– 8 –

15-EN

16-EN

EN

FR

7

Refrigerant piping

WARNING

•

If the refrigerant gas leaks during installation, ventilate the room.

If the leaked refrigerant gas comes into contact with

fi

re, noxious gas may be generated.

•

After installation, check that the refrigerant gas does not leak.

If the refrigerant gas leaks into the room and comes into contact with

fi

re such as a fan heater, stove, or

kitchen range, noxious gas may be generated.

■

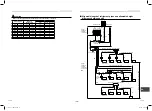

Connection of refrigerant pipe

• The service valves are inside the outdoor unit. To

access them, remove the front panel and the piping/

wiring panel. (M5: 9 pcs.)

• As shown in the illustration on the right, the hooks

are at the right and left sides of the front panel. Lift

up and remove the front panel.

• Pipes can be drawn out forward or downward from the

outdoor unit.

• To draw out the pipe forward, draw it out to the

outside via the piping/wiring panel, and leave a space

of 19.7" (500mm) or more from the main pipe

connecting the outdoor unit with the indoor unit,

considering service work or other work on the unit.

(For replacing the compressor, 19.7" (500mm)

or more space is required.)

• To draw out the pipe downward, remove the

knockouts on the base plate of the outdoor unit, draw

the pipes out of the outdoor unit, and perform piping on the right/left or rear side. Downward length of the balance

pipe should be 16.4 ft (5m) or less.

Ball valve of suction gas side

Ball valve of suction gas side

Ball valve of suction gas side

Ball valve of

discharge gas pipe

Ball valve of

discharge gas pipe

Ball valve of

discharge gas pipe

(MAP072)

(MAP096, 120)

(MAP144, 168)

Packed valve of liquid side

Packed valve of liquid side

Packed valve of liquid side

Packed valve of

balance pipe

Packed valve of

balance pipe

Packed valve of

balance pipe

REQUIREMENT

• For a brazing work of the refrigerant pipes, be sure to use nitrogen gas in order to prevent oxidation of the inside

of the pipes; otherwise clogging of the refrigerating cycle due to oxidized scale may occur.

• Use clean and new pipes for the refrigerant pipes and perform piping work so that water or dust does not

contaminate the refrigerant.

• Be sure to use two spanners to loosen or tighten the

fl

are nut. If a single spanner is used, the required level of

tightening cannot be obtained. Tighten the

fl

are nut with the speci

fi

ed torque. (If it is hard to loosen or tighten the

fl

are nut of the balance pipe or packed valve of the liquid side with two spanners, loosen or tighten the

fl

are nut

while holding the valve mounting plate with a spanner.)

Ball valve of discharge gas side

Do not clamp the service port

with two spanners, doing so may

damage the service port.

Do not apply refrigerating oil to the surface of

the flare.

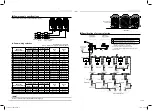

Unit: ft•lbs (N•m)

Outer dia. of

copper pipe

Tightening torque

Ø1/4 (6.4 mm)

10 to 13 (14 to 18)

Ø3/8 (9.5 mm)

24 to 31 (33 to 42)

Ø1/2 (12.7 mm)

37 to 46 (50 to 62)

Ø5/8 (15.9 mm)

50 to 60 (68 to 82)

Ø3/4 (19.1 mm)

74 to 88 (100 to 120)

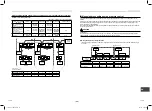

Pipe connection method (Example)

Draw-out forward

Draw-out downward

Suction-side gas

pipe

Cut the L-shaped pipe, then braze the

socket procured locally.

Suction-side gas

pipe

Cut the L-shaped pipe, then braze the

socket procured locally.

Discharge-side

gas pipe

Braze the supplied attachment pipe

and elbow procured locally.

Discharge-side

gas pipe

Braze the supplied attachment pipe

and socket procured locally.

Liquid pipe

Braze the supplied attachment pipe

and socket procured locally.

Liquid pipe

Braze the supplied attachment pipe

and socket procured locally.

Balance

pipe

Discharge-side

gas pipe

L-shaped

pipe

Suction-side

gas pipe

Pipe

Pipe

Pipe

Pipe

Socket

Socket

Elbow

Attachment

pipe

Attachment

pipe

Liquid pipe

Section

to be cut

Suction-side

gas pipe

Balance

pipe

Discharge-side

gas pipe

L-shaped

pipe

Suction-side

gas pipe

Pipe

Pipe

Pipe

Pipe

Socket

Socket

Socket

Attachment

pipe

Attachment

pipe

Liquid pipe

Section

to be cut

Suction-side

gas pipe

Hook

Front panel

Piping/wiring panel

(Rear piping)

(Right piping)

(Right

piping)

(Left piping)

(Left

piping)

19.7" (500mm)

or more

Drawing out forward

Drawing out

downward

1122001101_EN FR.indd 8

1122001101_EN FR.indd 8

6/27/16 4:58 PM

6/27/16 4:58 PM

•

After installation, check that the refrigerant gas does not leak.

If the refrigerant gas leaks into the room and comes into contact with fire such as a fan heater, stove, or

kitchen range, noxious gas may be generated.