WARNING

The blade is sharp; contacting the blade can result

in serious personal injury.

Wear gloves when servicing the blade.

1.

Disconnect the spark plug wire from the spark plug.

Refer to Preparing for Maintenance (page 13).

2.

Tip the machine onto its side, with the dipstick down.

3.

Use a block of wood to hold the blade steady

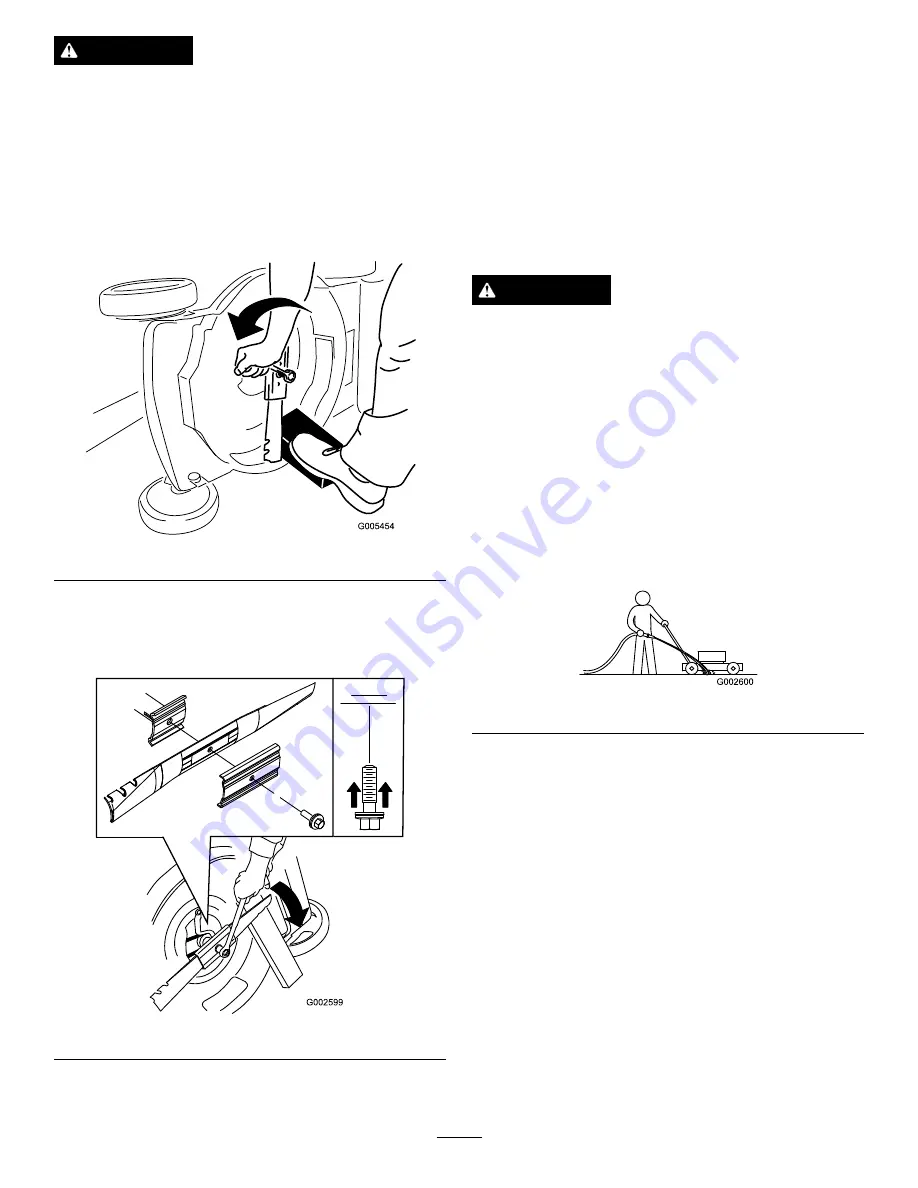

(Figure 39).

Figure 39

4.

Remove the blade, saving all mounting hardware

(Figure 39).

5.

Install the new blade (turn the blade bolt clockwise)

and all mounting hardware (Figure 40).

Figure 40

Important:

Position the curved ends of the blade

to point toward the machine housing.

6.

Use a torque wrench to tighten the blade bolt to

82 N-m (60 ft-lb).

Important:

A bolt torqued to 82 N-m (60 ft-lb) is

very tight. While holding the blade with a block

of wood, put your weight behind the ratchet or

wrench and tighten the bolt securely. This bolt is

very difficult to overtighten.

Cleaning the Machine

Service Interval:

Before each use or daily

WARNING

The machine may dislodge material from under the

machine housing.

•

Wear eye protection.

•

Stay in the operating position (behind the

handle).

•

Do not allow bystanders in the area.

1.

With the engine running on a flat paved surface, spray

a stream of water in front of the

right

rear wheel

Note:

The water will splash into the path of the blade,

cleaning out the clippings.

Figure 41

2.

When no more clippings come out, stop the water and

move the machine to a dry area.

3.

Run the engine for a few minutes to dry the housing

to prevent it from rusting.

Emptying the Fuel Tank

1.

Stop the engine and wait for it to cool down.

2.

Disconnect the wire from the spark plug.

3.

Remove the cap from the fuel tank.

4.

Use a hand pump to syphon the fuel into a clean

approved gasoline container.

5.

Connect the wire to the spark plug.

6.

Run the engine until it stops.

7.

Start the engine again to make sure that all the gasoline

is out of the carburetor.

17