Maintenance

Lubricating the Machine

Regularly lubricate the 6 grease fittings of each cutting unit

(

) with No. 2 lithium grease.

There are 2 lubrication points on the front roller, 2 on the

rear roller, and 2 for the reel bearing.

Note:

Lubricating the cutting units immediately after

washing helps purge water out of the bearings and

increases bearing life.

1.

Wipe each grease fitting with a clean rag.

2.

Apply grease until clean grease comes out of the roller

seals and the bearing relief valve.

3.

Wipe any excess grease away.

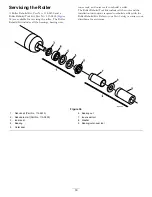

Figure 22

Grease fitting locations on left side

Relief-Grinding the Reel

The reel has a land width of 1.3 to 1.5 mm (0.050 to 0.060

inch) and a 30-degree relief grind.

When the land width gets larger than 3 mm (0.120 inch) wide,

do the following:

1.

Apply a 30 degree relief grind on all reel blades until

the land width is 1.3 mm (0.050 inch) wide (

and

).

Figure 23

Model 036321

1.

30 degrees

2.

1.3 mm (0.050 inch)

Figure 24

Model 03623

1.

1.3 mm (0.050 inch)

2.

30 degrees

2.

Spin grind the reel to achieve <0.025 mm (0.001 inch)

reel run-out.

Note:

This causes the land width to grow slightly.

Note:

To extend the longevity of the sharpness of the edge

of the reel and the bedknife—after grinding the reel and/or

the bedknife—check the reel-to-bedknife contact again after

cutting 2 fairways, as any burrs will be removed, which may

create improper reel-to-bedknife clearance and thus accelerate

wear.

14

Summary of Contents for 03621

Page 20: ...Notes 20 ...

Page 21: ...Notes 21 ...