l

Position the motor so that its cord points down when the

motor is engaged. Depending on the operational position

(horizontal or vertical), you may have to reposition the motor

with respect to the motor mount.

l

Make sure that the paint is maintained on the motor body —

in particular, the magnetic laminations in the center.

l

Examine the oil view port for a milky fluid or raw coolant.

To remove coolant from the rotary table:

1. Drain the coolant from the rotary table.

2. Refill with one of the following:

l

AGMA 2 gear oil

l

SAE 30 weight motor oil

About the Rotary Table and Coolant

The rotary table is designed to operate in the presence of coolant,

but not when it's submersed in coolant. It's rarely a problem is

coolant is dripping over the edge. However, it is a problem if there's

a serious external coolant flow that submerses the joint between

the rotating table and the base casting.

The electric motor is sealed against cutting fluids. Do not allow the

following components to be subject to constant coolant flow or

high-pressure coolant jets:

l

Motor

l

Motor cable

l

The joint between the rotating table and the base casting

About the Rotary Table Lubrication System

There is an oil distribution system internal to the rotary table. As the

table turns, it carries oil over the worm gear.

Note:

The distribution system does not cover the sliding

joint between the rotating table and the base casting,

which is similar to the slideways of a mill and has a large,

flat surface supported by an oil film.

The oil port on the edge of the rotary table (and on the base casting

itself) provides oil to the sliding surfaces. It's important to

occasionally oil the ports to maintain an oil film, which is essential

to keep water and coolant away from the sliding joint. If you're

using coolant, and you do not oil the ports, coolant will enter the

rotary table.

Note:

Coolant contains anti-corrosion agents which protect

the table surfaces. A small amount of coolant and oil

generally forms an emulsion, which you can see as a milky

fluid inside the oil view port.

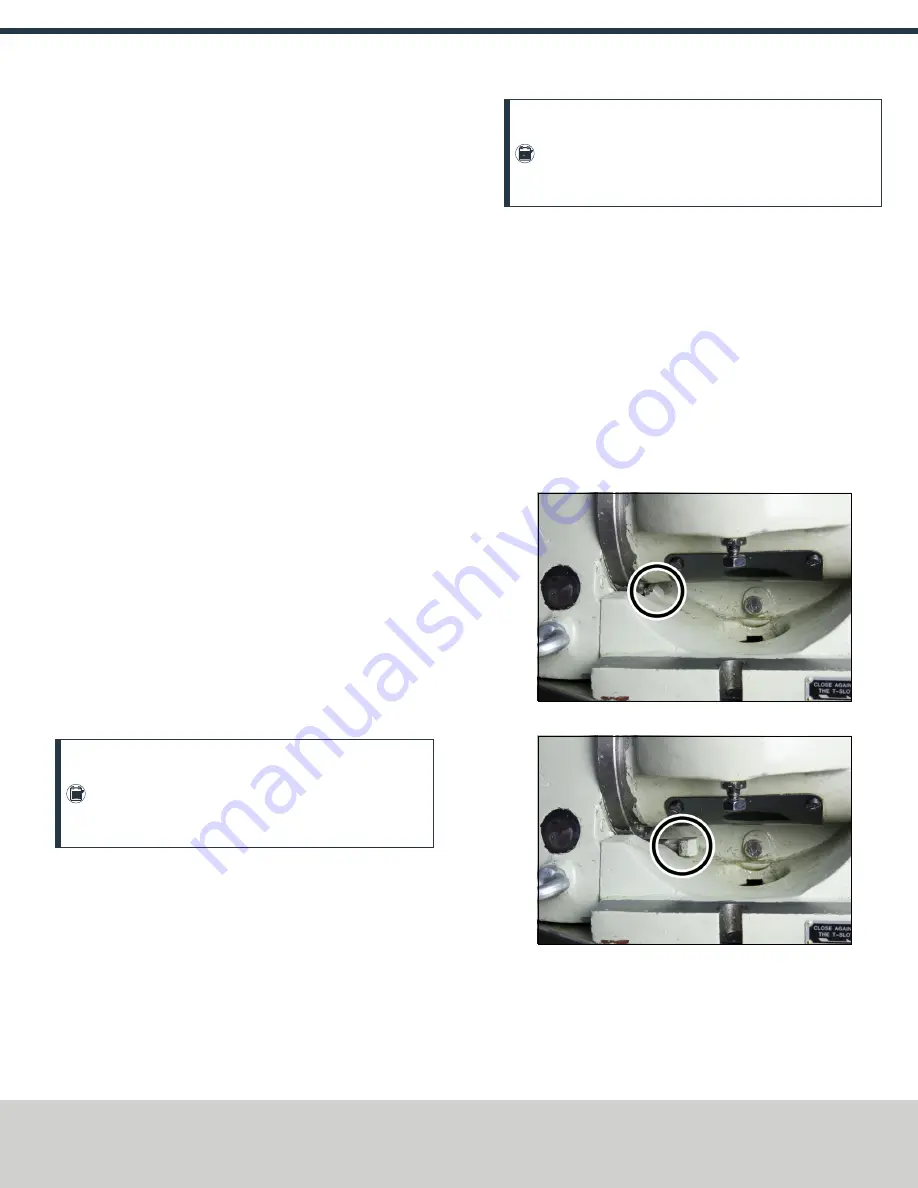

5.1.5 Examine the Locking Lugs

The 8-in. Tilting Rotary Table and 6-in. Tilting Rotary Table each

have two locking lugs. When they are moved out of position (either

intentionally or unintentionally), the rotary table will not tilt within

the full range of motion. The more interior locking lug is difficult to

realign with the recessed groove.

To manually align the interior locking lug:

1. Manually crank the handle and move the table to a position

that allows access to the displaced part.

2. Use your fingers (or a small tool) to move the locking lug back

into place. In its correct position, you should only see the cap

of the locking lug.

Figure 5-7: Example of the locking lug in the In position.

Figure 5-8: Example of the locking lug in the Out position.

5.1.6 Examine the Motor Coupling

If a motor coupling is loose or cracked, the table will slip relative to

motor rotation and, subsequently, lose position.

Page 11

©Tormach® 2019

Specifications subject to change without notice.

tormach.com

TD10552: Owner's Guide: 4th Axis (0919A)

TECHNICAL DOCUMENT