IT

APPENDIX

6

6.1

MAINTENANCE

6.2

ACCESSORIES AND SPARE PARTS ON REQUEST

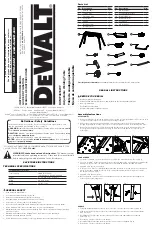

N.1 Digital program selector (mod. Ds2);

N.2 Ultra flat wall button;

N.1 Program selection knob (mod. KC1);

N.1 Program selection knob (mod. MS1);

N.2 Miniaturized photocells (mod. F1 and mod F2);

N.2 Infrared sensors (mod. IS1 and IS2);

Do not use spare parts and accessories that are not original as this could affect the safety and efficiency of the automation.

Original spare parts and accessories must be requested exclusively from the authorized retailer or directly from the

factory, communicating the type, model, serial number and year of construction of the automation:

Antipanic door opener (simple or complete);

System for glass door;

N.1 Electromechanical door block;

Lateral sensors.

Should arise the need to use accessories other than those mentioned, the installer can apply directly to our technical

support service.

N.2 Microwave sensors (mod. WS1);

if worn, replace the central gaskets and brushes on the doors.

Model K500

replace the glide belt.

replace the gearmotor and electronics

The words “Wheel replacement” appear on the digital switch

:

@

The duration of the battery pack is affected by the environmental and functional conditions of the automation.

Every 1,000,000 cycles (the words “Belt replacement ” appear on the digital switch)

:

Double wing door up 500kg : Every 300.000 cycles

with the automation powered, check the stability of the door ensuring that the movement is regular without friction;

disconnect the power supply and check that the emergency battery system opens the doors in the entirety of the

passageway;

Every 250,000 cycles or 1 year (the words “Rubber

replacement” appear on the digital switch)

:

/guides

replace the carriage wheels

Every 24 months (the words “Battery replacement” will appear on the digital switch):

replace the rubber stops and guides on the floor of the trolleys

Double wing door up 280kg: Every500.000 cycles

Every 500,000 cycles or 10 years (the words “gear motor/electr. ” appear on the digital switch)

:

replace the emergency battery system (after disconnecting the power supply).

In order for the automation unit to operate correctly, the user shall be carried out periodical maintenance on the same.

This maintenance activity may be carried out either by TOPP, in accordance with a specific agreement made with the

user, or by the installation technician or by other competent and qualified technical personnel in possession of all legal

requirements.

IMPORTANT! – During maintenance operations, the personnel shall be equipped with suitable personal protection

equipment (PPE) so as to perform the works required under safe conditions.

At the end of the cycles or data entered manually by the maintenance personnel, the '

hex wrench'

symbol will appear on

the display to indicate that maintenance is needed. This 'alarm' can be reset by the maintenance personnel.

The maintenance activities should in any case involve the periodical execution of at least the following operations:

Every 6 months (the words “Check/cleaning” will appear on the digital switch):

clean the glide surface of the carriages and wheels, using a cloth lightly moistened with solvent;

clean the glasses of the activation and safety sensors with a cotton cloth slightly moistened with water. Do not use

solvents or other aggressive products;

verify the correct operation of the sensors;

make sure there are no uncovered areas in the vicinity of the mobile doors that are not detected by the sensors;

check the correct alignment of the doors and position of the door on the jamb when closed;

verify the correct operation of the photocells, if any, the blocking system and their fastenings;

check the connections and electric wiring;

check the belt tension, the stability of the automation and the tension of all the screws;

39

INSTRUCTIONS FOR INSTALLATION AND USE

EN

K500