172-65451MA-04 (JH5RL-X) 3 Jul 2018

9

Disassembly/Reassembly

NEVER apply direct heat to the float. The float may explode due to

increased internal pressure, causing accidents leading to serious injury

or damage to property and equipment.

WARNING

Use hoisting equipment for heavy objects (weighing approximately

20 kg (44 lb) or more). Failure to do so may result in back strain or other

injury if the object should fall.

CAUTION

When disassembling or removing the product, wait until the internal

pressure equals atmospheric pressure and the surface of the product

has cooled to room temperature. Disassembling or removing the

product when it is hot or under pressure may lead to discharge of fluids,

causing burns, other injuries or damage.

CAUTION

Use the following procedures to remove components. Use the same procedures in

reverse to reassemble. (Installation, inspection, maintenance, repairs, disassembly,

adjustment and valve opening/closing should be carried out only by trained

maintenance personnel.)

Drain Plug (Option)

Part

During Disassembly

During Reassembly

Drain Plug

Remove with a socket

wrench

Consult the table of tightening torques and

tighten to the proper torque

Drain Plug

Gasket

Remove the gasket and

clean sealing surfaces

Replace with a new gasket; coat surfaces with

anti-seize

Detaching/Reattaching the Cover

Part

During Disassembly

During Reassembly

Cover Nut

Remove with a socket

wrench

Consult the table of tightening torques and

tighten to the proper torque

Cover

Remove by lifting up and

off

Make sure there are no pieces of the old

gasket left on the sealing surfaces of the

body and cover, align the arrows on the body

and cover and reattach

Connector

Remove the connector

Reinsert into the hole in the body

Connector

Gasket

Remove the gasket and

clean sealing surfaces

Replace with a new gasket

Cover Gasket

Remove the gasket and

clean sealing surfaces

Replace with a new gasket

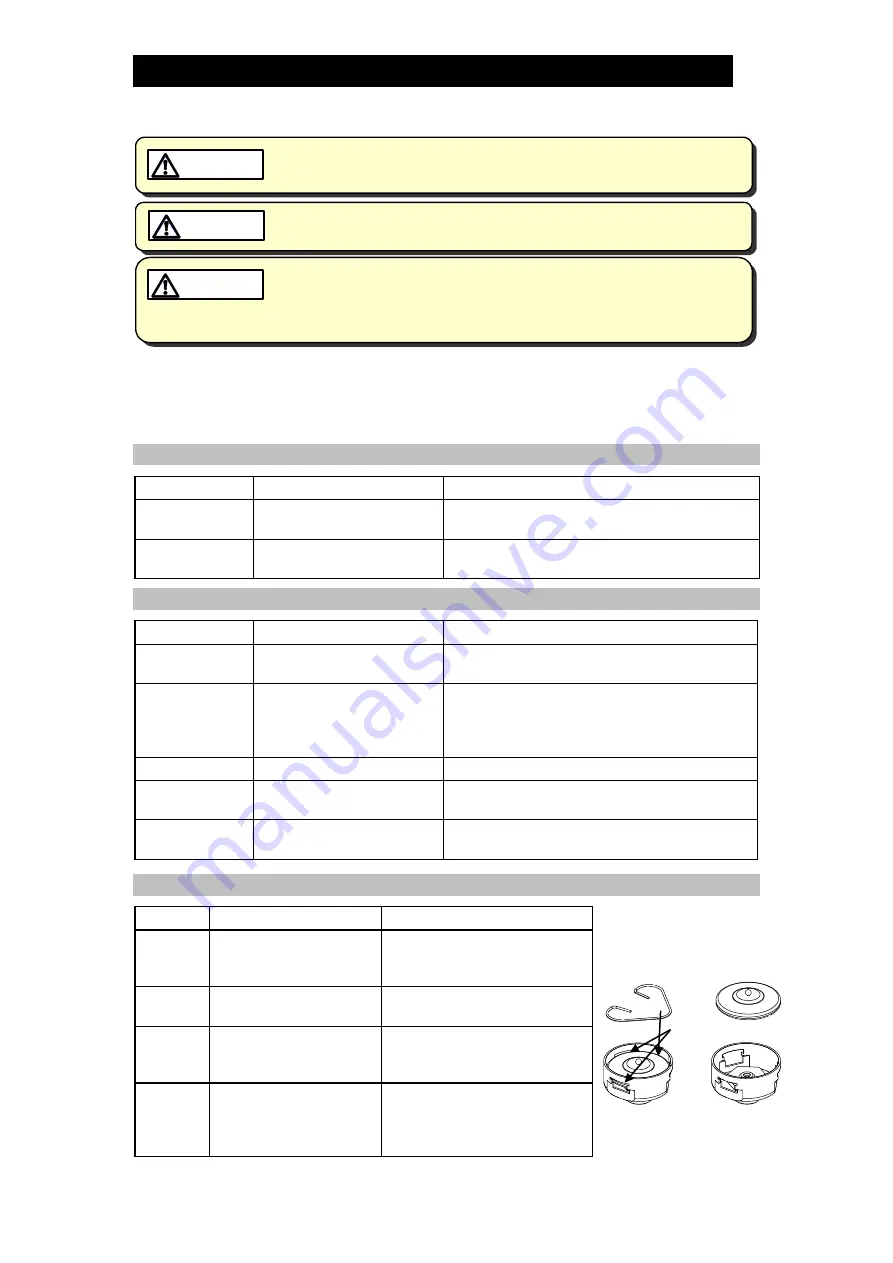

Disassembly/Reassembly of Components Inside the Cover

Part

During Disassembly

During Reassembly

Spring

Clip

Pinch the insides

together and remove

from the X-element guide

Insert securely into the groove

in the guide (fig. A)

X-element Remove from the

X-element guide

Insert after making sure of the

correct orientation (fig. B)

Air Vent

Valve

Seat

Remove with a socket

wrench

Consult the table of tightening

torques and tighten to the

proper torque

X-element

Guide

Remove without

bending

Fix with the Air Vent Valve

Seat and make sure that the

X-element can be inserted

smoothly

Figure A Figure B

Groove