HALO Users Manual

Revision G

44

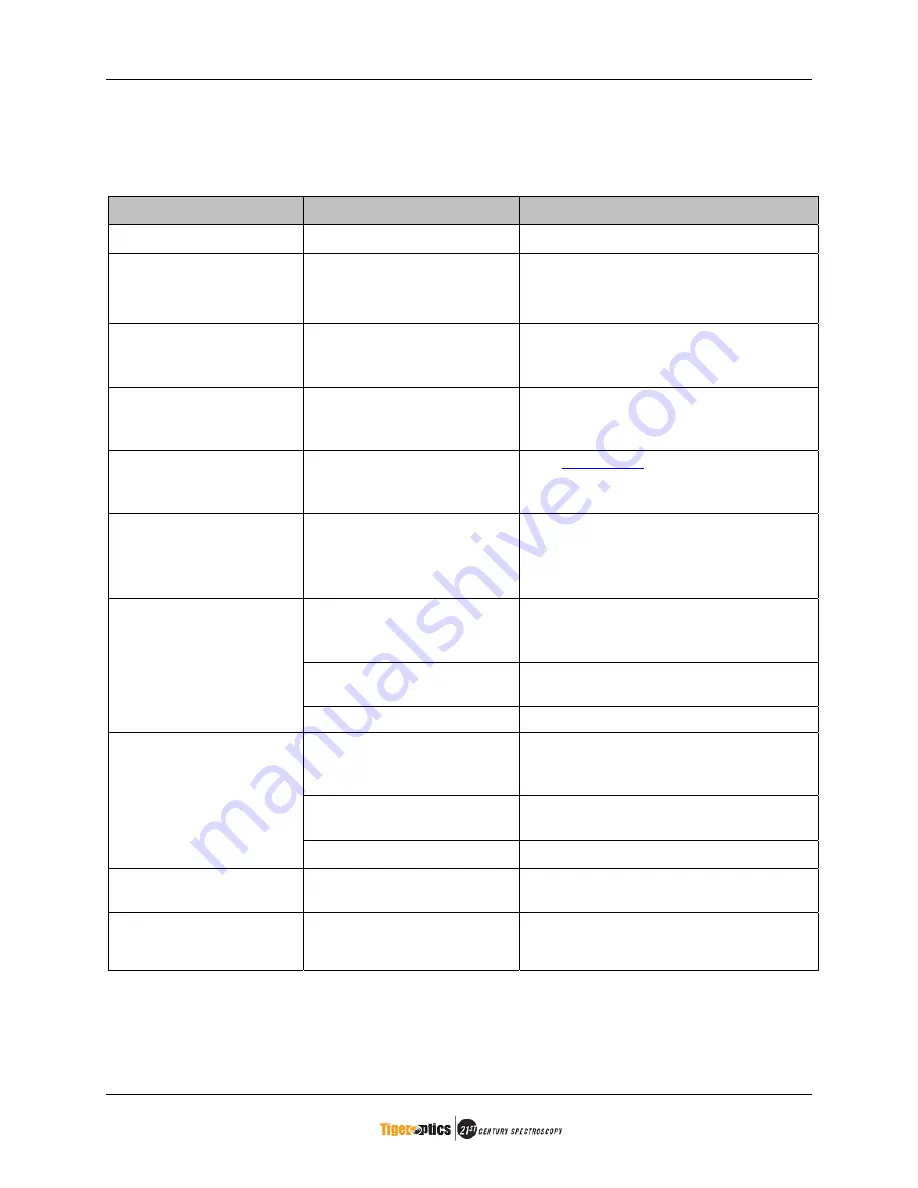

7.3 Troubleshooting Guide

Table 7-1 contains a troubleshooting guide of the most common problems associated with the

unit’s operation. System Fault alarms are included in the Table. If none of these step helps to

resolve the problem, contact trained Tiger Optics service personnel immediately.

Table 7-1 Troubleshooting

Circumstance

Probable Cause

Corrective Action

No display

Unit not powered up

Check fuse and plug.

Reading higher than

expected

Dead-legs, leaks, or

moisture traps in the

sampling system

Follow the “Preparing the Sample

Line” and “Leak Check” procedures.

Slow response time

Dead-legs, leaks, or

moisture traps in the

sampling system

Follow the “Preparing the Sample

Line” and “Leak Check” procedures.

Reading continues to

decrease

Reading not yet stable

Purge with dry gas then reapply the

sample. Repeat as often as required

until the reading stabilizes.

Not reading correct

concentration of a span

gas

Incorrect gas type chosen. See

Section 4.2

Reading is erratic

Contaminated optics

Consult with factory.

Fine air leaks in sample

line

Leak test the sample line and

connections following the procedure in

Table 3-3.

Fine air leaks in sample

cavity

Leak test following the procedure in

Table 3-3.

Reading is noisy

Optics need re-alignment

Consult with factory.

Above the maximum ring-

down value, too much

water.

Stop and purge the unit with a dry gas

until on scale.

Optical bench out of

alignment

Consult with factory.

Ring-down Alarm

Detector failure

Consult with factory.

Ring-down Fault and

Laser Current Fault

Laser is not operating

Check that there is current. If not,

consult factory.

Ring-down Fault and

Laser Temperature

Fault

Temperature controller has

failed

Consult with factory.