33

V

alue

S

erieS

V-710DM M

anual

Feed belts are

operating, but ma-

terial not feeding

(continued)

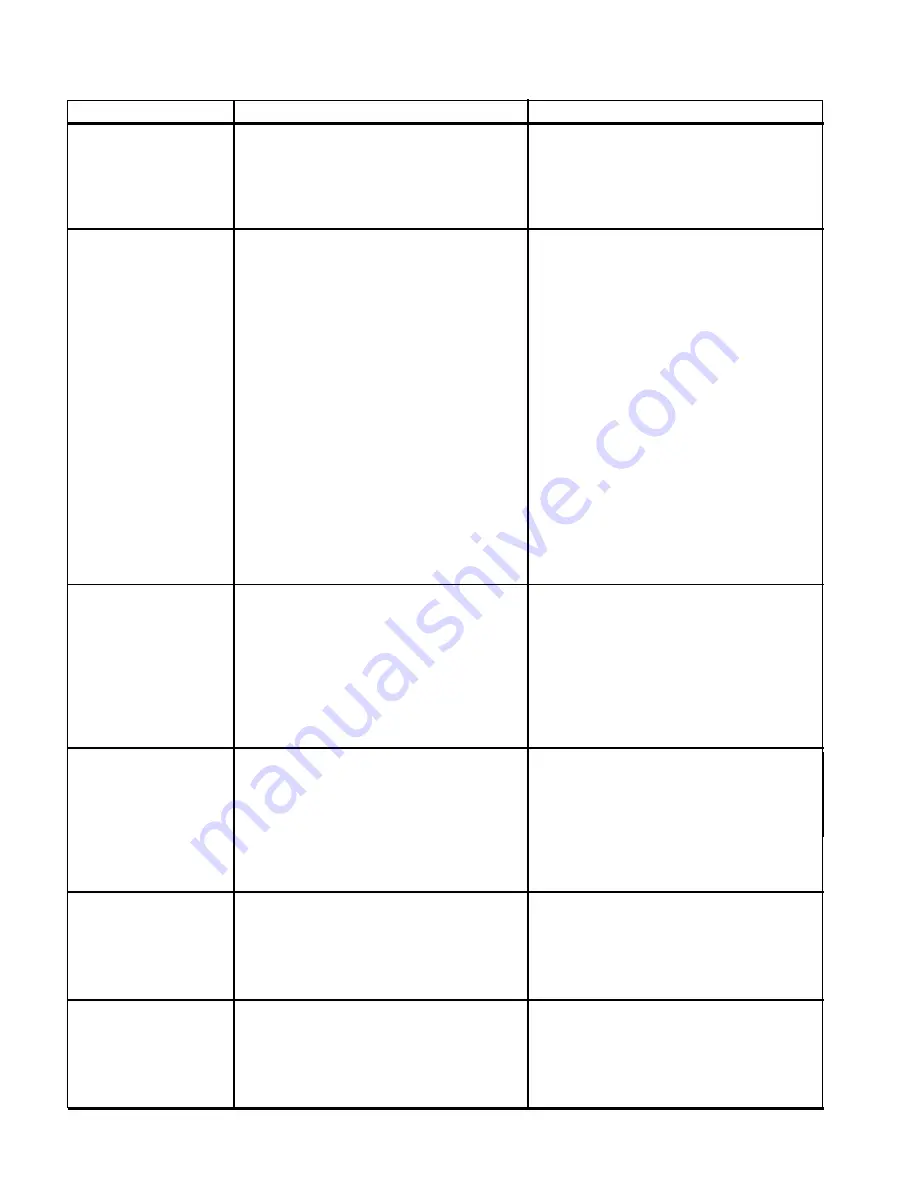

Problem

Cause

Solution

5. Gate assembly may be down too tight.

6. Too much weight in hopper.

1. Excessive weight in hopper.

2. Excessive down pressure on gate as-

sembly.

3. Off-centered product from center point

of machine.

4. Stack is bearing down on edge of belt.

5. Belt wear.

6. Rollers out of adjustment.

1. Improperly adjustment in one or more

of the following:

• gate assembly

• back wedge

1. Back wedge not aligned properly.

2. Hold down spring tension too tight or

too loose.

3. Improperly adjusted gate horizon.

1. Photo sensor "staging" leading edge of

material too far from hopper plate.

2. Gripper jaw adjusted too far from edge

of hopper plate.

1. Photo sensor "staging" leading edge of

material too far past hopper plate.

2. Gripper jaw adjusted too close to lead-

ing edge of hopper plate.

Review gate assembly adjustment

procedure.

Remove material from stack. Test

again.

Reduce weight. Test again.

Rotate gate adjustment 1/8 turn to

increase gap and manually test. Review

gate assembly adjustment procedure.

Review side guide setting procedure.

Move stack away from belt, even if this

causes stack to be off center from cen-

ter line of feeder.

Review gate assembly adjustment

procedure. Also review inspection and

care procedures. If wear is excessive,

consult with a qualified technician.

Consult with a qualified technician.

1. Turn the Power switch to "Off" by

pressing the circle (O).

2. Remove jammed material from

feeder. While doing so, try to deter-

mine the cause of the jam.

3. Verify each adjustment by reviewing

the "Preparing for Operation" section

of the manual.

Review back wedge adjustment proce-

dure.

Review hold-down spring installation

procedure.

Review gate assembly adjustment

procedure.

Review photo sensor adjustment proce-

dure.

Adjust gripper jaw as required per in-

serter owner's manual.

Review photo sensor adjustment proce-

dure.

Adjust gripper jaw as required per in-

serter owner's manual.

Feed belt(s) not

tracking on rollers

Material skewing

Material too far

from gripper jaw

(Inserter Applica-

tions only)

Table 5-1.

Quick-Look Troubleshooting (continued)

Jamming occurs

during operation

Material too deep

in gripper jaw (In-

serter Applications

only)

Summary of Contents for Streamfeeder V-710DM

Page 1: ...Manual Value Series V 710DM ...

Page 7: ...v Value Series V 710DM Manual ...

Page 47: ...40 Value Series V 710DM Manual 7 Mechanical Components BASE FEATURES ...

Page 49: ...42 Value Series V 710DM Manual BASE FEATURES ...

Page 51: ...44 Value Series V 710DM Manual CARRIAGE ASSEMBLY Assembly 10501102 ...

Page 55: ...48 Value Series V 710DM Manual HOLD DOWN ASSEMBLY Assembly 10501109 ...

Page 57: ...50 Value Series V 710DM Manual GATE PLATE ASSEMBLY Assembly 84111006 ...

Page 59: ...52 Value Series V 710DM Manual TRIANGLE WEDGE ASSEMBLY Assembly 63311018 ...

Page 61: ...54 Value Series V 710DM Manual 8 Electrical Components ...

Page 62: ...55 Value Series V 710DM Manual ...

Page 63: ...56 Value Series V 710DM Manual ...

Page 64: ...57 Value Series V 710DM Manual ...

Page 71: ...64 Value Series V 710DM Manual ...

Page 72: ......