P a g e

|

5

26-1-16

Limited access to the control parameters is available. The operator can alter the

temperature set point and has access to a parameter used for calibration purposes.

4.

TO CHANGE THE SET TEMPERATURE:

•

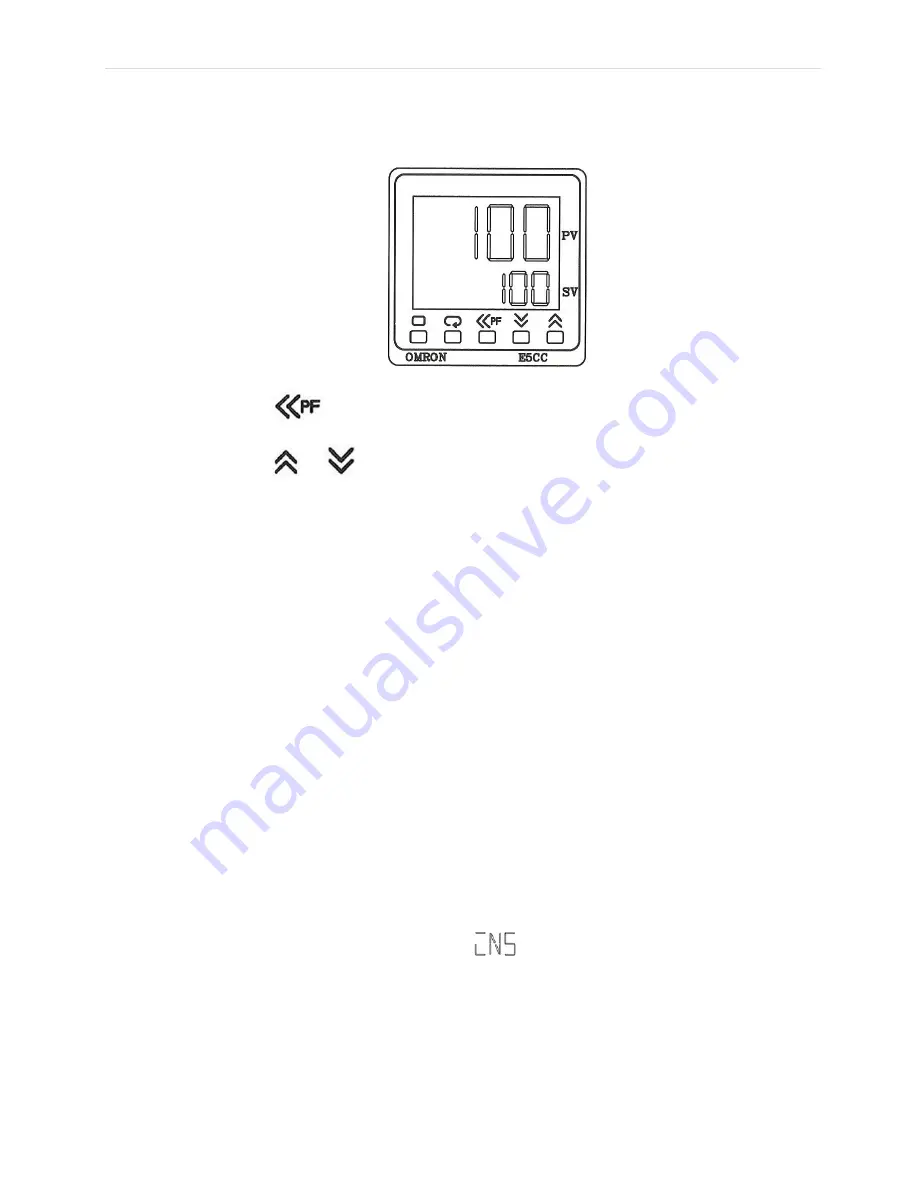

Use the

button to move the cursor, the digit will flash indicating that it can

be changed.

•

Use the

or

arrows to change the temperature. When the desired

temperature is set leave for a few seconds and the digits will stop flashing to

confirm entry.

5.

OVER TEMP LIGHT:

The temperature control has been configured with automatic over

temperature alarm. In case of a malfunction the alarm will turn off all forms of heating

when the oven temperature is more than 5ºC above the set temperature. In this

instance the red “over temp” alarm light will be illuminated.

6. These ovens are fitted with an air exhaust vent on the top for drying. Adjust the vent to

increase or decrease the drying rate, (fully open for maximum drying).

SENSOR CORRECTION:

There are a number of factors that will affect the accuracy of the temperature displayed in

relation to the actual temperature inside the oven, these include the following:

•

Product load inside the oven (the load should be distributed evenly across each shelf

with room for vertical air flow around the product).

•

Oven temperature (at higher temperatures the heat loss from the oven will be greater).

•

Location of the sensor (the temperature sensor can never be placed in the centre of the

oven because it could be damaged).

Because of the above factors it may be possible to have an error between the temperature

displayed and the temperature measured at the middle of the oven. For this reason the Omron

temperature control has a parameter that can be used to correct the temperature displayed.

This sensor correction parameter is displayed as

.

In simple terms this parameter adds or subtracts a correction value to the displayed

temperature to make it read the correct temperature. The calibration parameter can be

accessed as follows:

•

Prior to any calibration of the temperature display ensure that the equipment used to

measure the oven temperature has a current certificate of calibration to a traceable

source, and that you are confident that it is accurate.