- 20 -

Resistivity

Sensor

The controller displays and maintains resistivity between adjustable setpoints.

If the resistivity goes above the high setpoint, the line through the DI cartridge

closes. Flow through the DI cartridge resumes when the resistivity drops to the

low setpoint. If the resistivity drops below the low setpoint for more than one

hour, a fault is displayed, the REPLACE CARTRIDGE LED illuminates and a

remote signal is generated.

NOTE:

Every time the controller is energized, a four hour clock disables the

REPLACE CARTRIDGE fault.

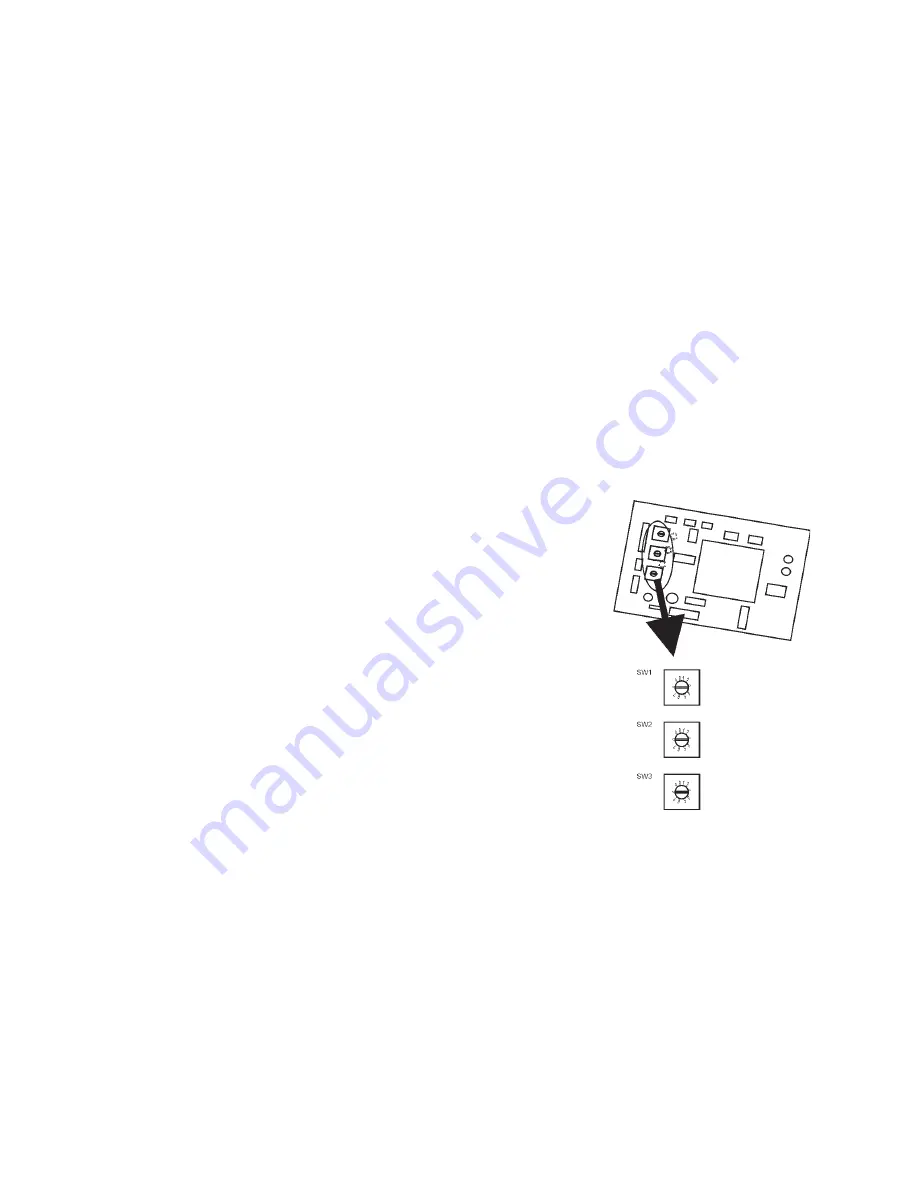

Devicenet

The Node Address and baud rate are all set with three rotary switches on the

devicenet board, see illustration below.

SW1 and SW2 are used to set the MAC ID. The MAC ID can be set from 1 to

63. It is factory set at 60. SW1 is the Most Significant Digit (MSD) and SW2 is

the Least Significant Digit (LSD). To set the device to a MAC ID of 60, set

SW1 to 6, SW2 to 0.

SW3 is used to set the baud rate. The baud

rate is factory set to 500K.

SW3 position

0 = 125K

1 = 250K

2 = 500K

3 = Blank

NOTE:

If the baud rate is changed, recycle

the controller for it to read the change.