TK 56433-5-MM-EN

37

Fuel Return Line Replacement

The fuel return lines (hoses) and end cap on the fuel

injection nozzles should be changed every 10,000

engine operating hours. The return line kit (P/N 10-373)

contains new return lines, clamps, an end cap, and a

decal like the one shown below. The decal is located

near the unit serial plate. The date and engine hours

must be entered on the decal when the fuel return lines

are changed.

Figure 16.

Fuel Return Line Replacement Decal

Use the following procedure to replace the fuel return

lines and end cap.

1. Remove the clamps, the end cap, the short fuel

return lines between the injection nozzles, and the

long fuel return line from the injection nozzle to the

banjo fitting on the injection pump.

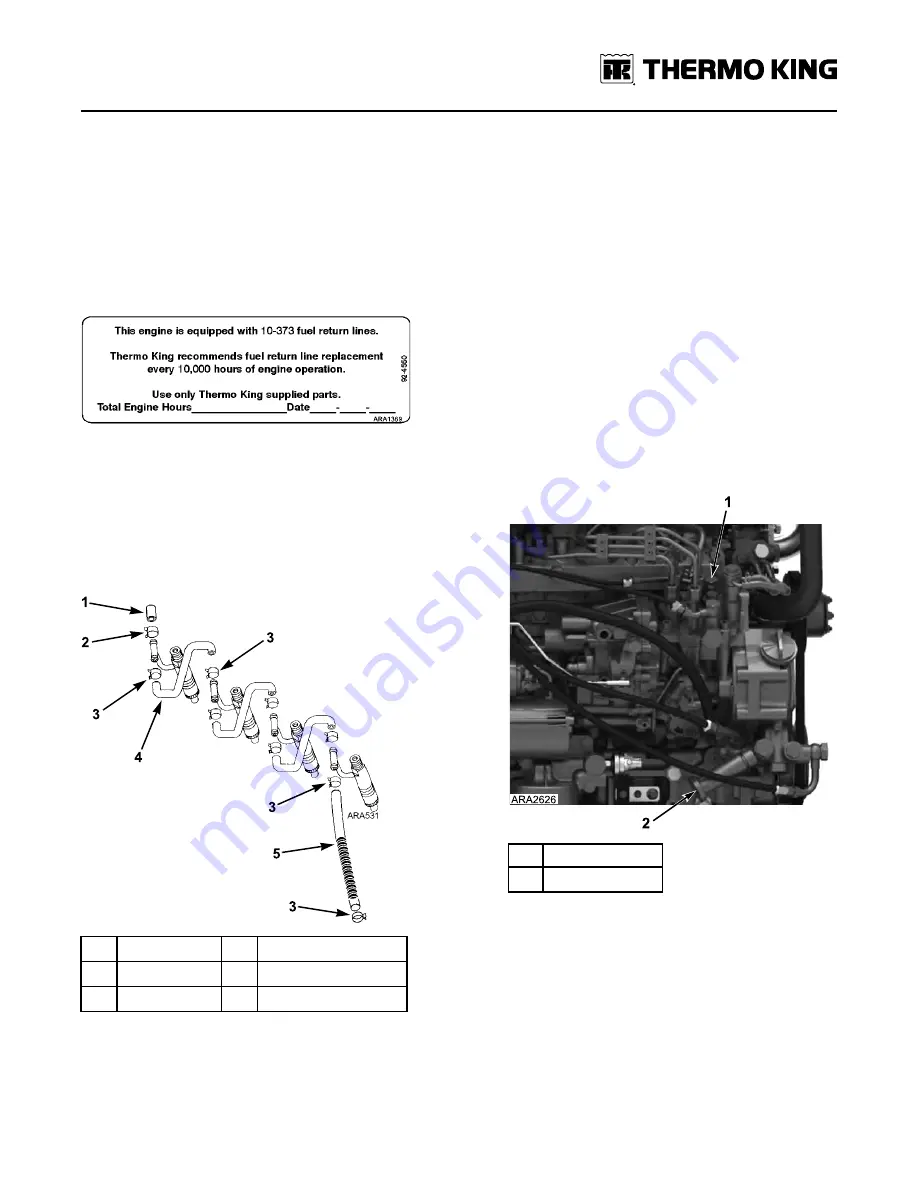

Figure 17.

Fuel Return Line Replacement

1.

End Cap

4.

Short Fuel Return Lines

2.

Larger Clamp

5.

Long Fuel Return Lines

3.

Smaller Clamps

2. Discard the old clamps, end cap, and fuel return

lines.

3. Install the end cap and clamp. Note that the end cap

has a larger OD than the other hoses and requires

the larger clamp.

4. Install the fuel return lines and clamps. It may be

necessary to adjust the banjo fitting slightly to

obtain the straightest routing for the long return

line.

5. Be sure all the fittings are tight and check for leaks.

6. Write the date and engine hours on the decal.

Bleeding the Fuel System

If the engine runs out of fuel, repairs are made to the

fuel system, or if air gets into the system for any other

reason, the air must be bled out of the fuel system.

N

No

otte

e:: Make sure the fuel tank vent is kept open. If the

vent becomes clogged, a partial vacuum

develops in the tank, and this increases the

tendency for air to enter the system.

To bleed air from the fuel system:

1. Loosen the bleed screw about one turn.

Figure 18.

Injection Pump

1.

Bleed Screw

2.

Priming Pump

2. Unscrew the priming pump handle and manually

prime the fuel system until air bubbles are no

longer visible in the fuel coming out of the bleed

screw.

3. Tighten the bleed screw and screw the priming

pump handle back in.

4. Loosen the injection lines at the injection nozzles.

5. Crank the engine until fuel appears at the nozzles.

6. Tighten the injection lines.

7. Start the engine and observe the engine run for a