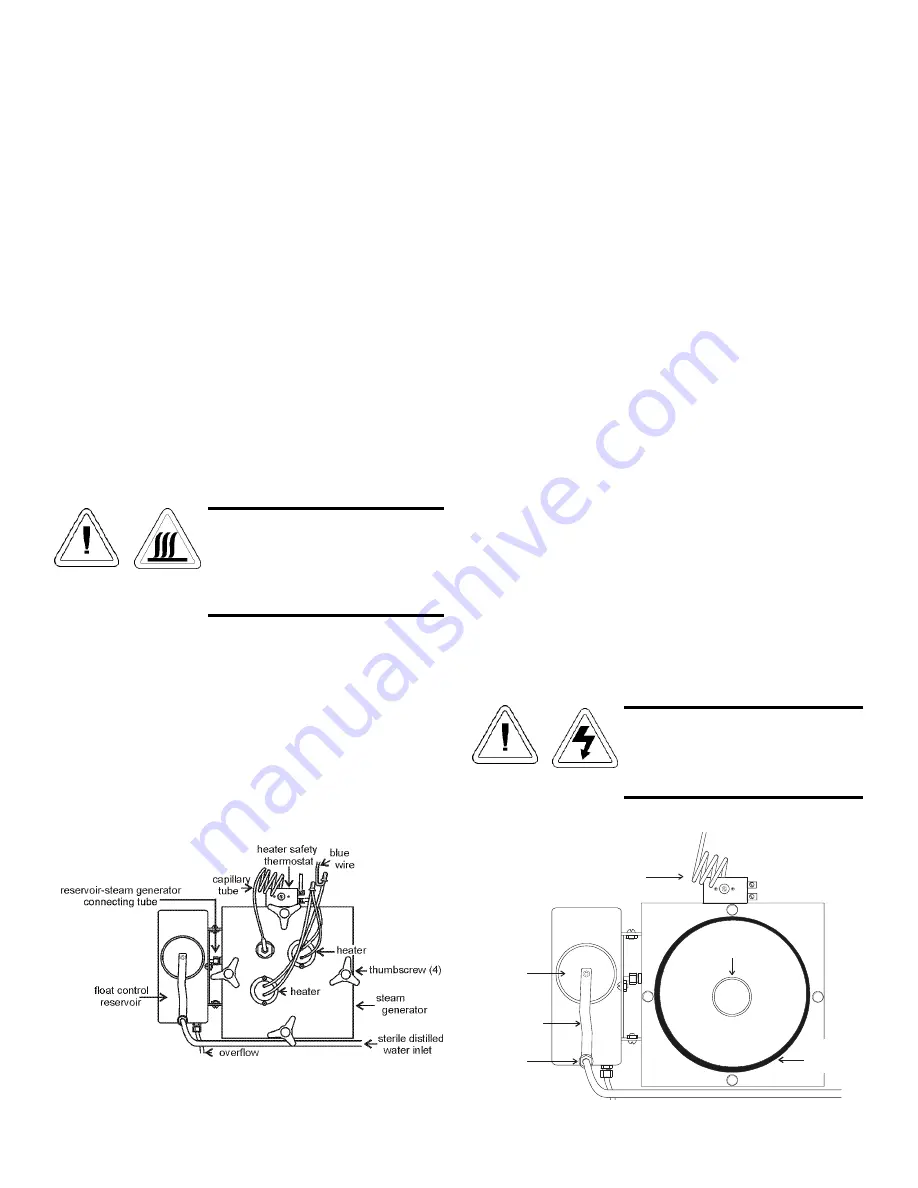

5.7 Cleaning and Adjusting the Humidity Steam

Generator, P/N 505087

Depending upon the quality of water used in the humidifi-

cation system, it may be necessary to clean the humidity gener-

ator and immersion heaters every 2 to 3 months.

Materials Required:

6-foot stepladder

Flat and Phillips screwdrivers

Clamp-on style Ammeter

Laboratory disinfectant

Siphon, sponge, & cleaning materials

1.

Remove all contents from the incubator, shut it off, and

disconnect the power.

2. Turn off the valve supplying the sterile distilled water.

3. From the stepladder, remove the eight Phillips screws

securing the top of the incubator cabinet.

4. When the steam generator has cooled, remove the four

thumbscrews.

The internal temperature of the

steam generator is hot enough to boil

water. Make certain sufficient time is

given to allow the unit to completely

cool before removing the top.

5. Lift the top off of the steam generator and lay it to the

side taking care to not crimp the copper capillary tube.

6. Siphon all of the water out of the steam generator and

clean it with a good quality laboratory detergent and dis-

infectant. Do not use any type of chloride cleaner. A

bristle brush may be needed for stubborn rust and scale.

Also clean the inside of the standpipe using a test tube

brush. Siphon and sponge the wash water out of the

boiler. Repeat cleaning with soap and water as neces-

sary.

7. Carefully pry off the brass top of the float control reser-

voir. Clean and disinfect it and the connecting tube

between the reservoir and the steam generator being

careful to not damage the float assembly.

8. Clean the two heater elements and the part of the copper

capillary tube attached to them.

9. When all surfaces are clean, rinse with sterile distilled

water until all soap and disinfectant are removed.

10. Open the distilled water valve and allow the reservoir to

fill. Measure the water level. The limit is three inches,

plus or minus one-quarter of an inch. The water level is

raised and lowered by carefully bending the float arm.

When set, replace the cover.

11. Replace the top of the steam generator and alternately

tighten the four thumbscrews to evenly compress the

rubber gasket.

a. Checking the Steam Generator Safety

Thermostat Calibration

1. Turn the slotted rheostat shaft of the temperature control

on the back of the steam generator fully clockwise.

2. Remove all tools and cleaning materials from the top of

the incubator. Reconnect power to the unit and turn it

on.

3. Set the RH level to 100% and open the incubator door.

This will cause the heaters in the steam generator to be

continuously energized.

The next step requires working in the

top section of the incubator where

high voltages are present. This should

only be done by qualified persons.

Models 3940 and 3949 _____________________________________________________________________________Service

5 - 3

Figure 5-2

float

valve

float

float

arm

capillary

tube

rubber

gasket

standpipe

Figure 5-3