Manual 0-2583

31

SERVICE

4. Remove the torch head from the leads (refer to Sec-

tion 5.06, Servicing Machine TorchComponents or

Section 5.07, Servicing Hand Torch Components).

5. With the torch head disconnected from the leads,

measure the resistance between negative cathode

body of the torch head (where the electrode seats)

and the positive anode body of the torch head (the

outer threads where the shield cup seats).

Infinite resistance (no continuity) should be mea-

sured between negative and positive sections of

the torch head.

If any current can flow through the center insula-

tor, the torch head is faulty and must be replaced.

If the torch head is okay, the problem is in the leads

assembly. Proceed to paragraph "B' to check torch

lead assembly.

B. Checking Torch Lead Assembly

Check the torch leads by measuring the resistance be-

tween the positive pilot lead connector and the negative/

plasma lead fitting.

If continuity is found, replace the torch leads.

If no continuity is found, the torch leads are probably

good. The torch leads should be tested further for insu-

lation breakdown if no other fault can be found. To test

the torch leads for insulation breakdown use the follow-

ing procedure:

WARNINGS

This procedure should be performed only by a quali-

fied electronic technician.

a. Remove the shield cup, tip, gas distributor, and

electrode from the torch head assembly if not al-

ready done.

b. Connect a Hi-Pot Tester capable of producing

2500VAC between the positive pilot lead and the

plasma (negative) lead fittings.

c. Increase the output of the Hi-Pot Tester to a maxi-

mum of 2500VAC.

If the voltage drops to 0VAC then the insulation be-

tween the torch leads is breaking down and the leads

must be replaced.

Carefully reassemble the components and recheck the

completed assembly per paragraph 'A', Step 3 to confirm

that the components have been properly assembled.

This completes the checks for the proper operation of the

center insulator of the torch head and leads. Proceed to

paragraph 'C' to check pilot and switch control wires..

C. Checking Pilot and Switch Control Wires

1. Disassemble the torch head and leads to expose

the torch head connections. Refer to Section 5.06,

Servicing Machine Torch Components or Section

5.07, Servicing Hand Torch Components.

2. Visually check that the PIP wires, torch switch wires,

pilot lead connection, and negative/plasma lead

connections are properly connected and in good

condition (no shorts or arcing).

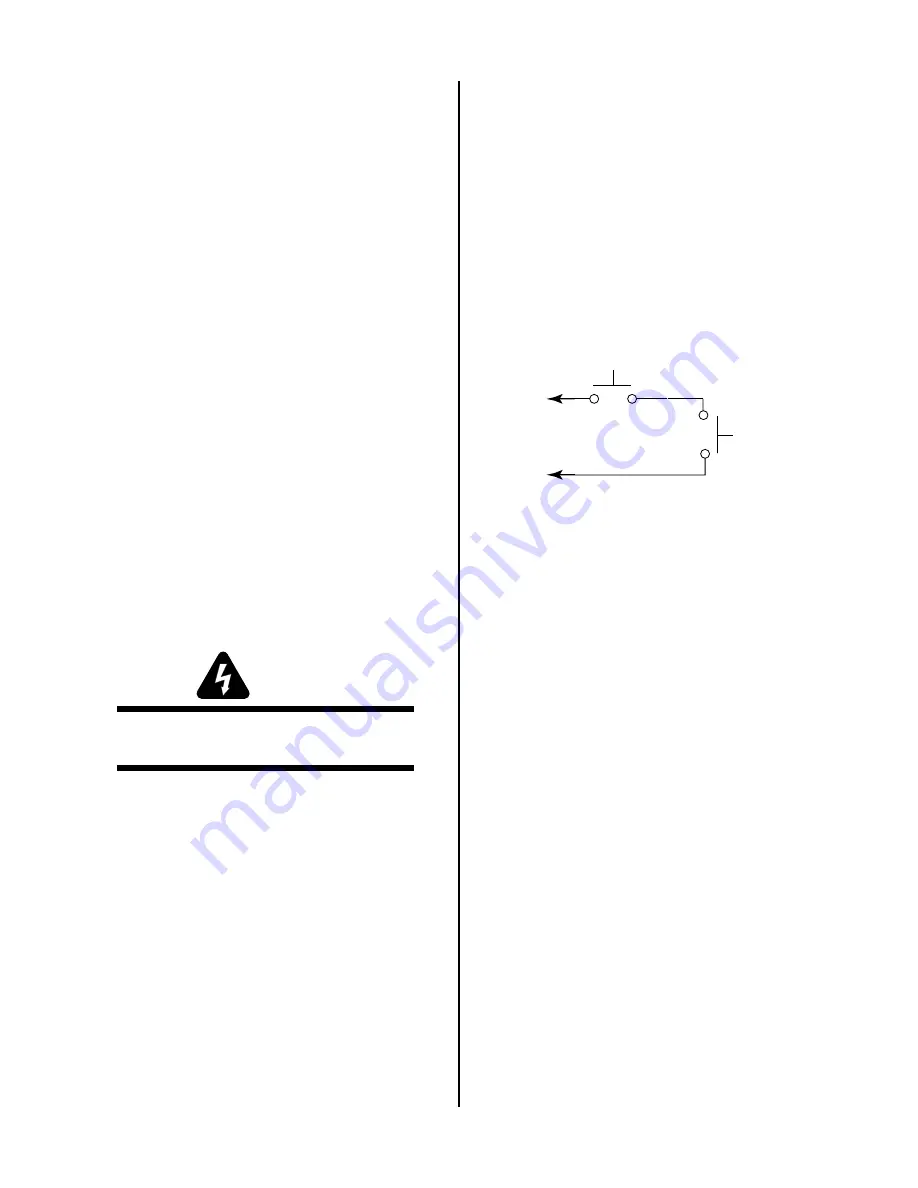

A-00458

Torch Switch

PIP Pin

PIP Pin

Shield Cup

To Control

Cable Wiring

Figure 5-9 Torch Switch and PIP Schematic

If problems are evident, repair or replace as re-

quired.

If there are no visual problems then proceed to

Step 3.

3. Check the pilot and switch control wires for opens

from one end of the torch leads to the other.

If open replace torch leads.

4. Check the pilot and switch control wires for shorts

to other components in the torch leads.

If shorted then replace torch leads.

5. Carefully reassemble the torch and leads.

D. Torch Leads Replacement

1. Disconnect the torch gas, pilot control wire and

torch control cable connections from the power

supply.

2. Pull the defective leads from the power supply.

3. Remove the torch head assembly as described Sec-

tion 5.06 Servicing Machine Head Components,

or Section 5.07 Servicing Hand Torch Components.

5. Connect the replacement torch lead gas, pilot con-

trol wire and torch control cable connection to the

power supply.

7. Install the torch head assembly onto the replace-

ment leads.

Summary of Contents for PCH-100XL

Page 2: ......

Page 6: ......

Page 18: ...INTRODUCTION DESCRIPTION 12 Manual 0 2583...

Page 22: ...INSTALLATION PROCEDURES 16 Manual 0 2583...

Page 38: ...SERVICE 32 Manual 0 2583...