Manual 0-2583

23

OPERATION

tance for optimum speed and cut quality. Clean spat-

ter and scale from the shield cup and the tip as soon

as possible. Spraying or dipping the shield cup in

anti-spatter compound will minimize the amount of

scale which adheres to it.

4.09 Recommended Cutting Speeds

Cutting speed depends on material, thickness, and the

operator’s ability to accurately follow the desired cut line.

The following factors may have an impact on system per-

formance:

• Torch parts wear

• Air quality

• Line voltage fluctuations

• Torch standoff height

• Proper work cable connection

NOTE

This information represents realistic expectations

using recommended practices and well-maintained

systems. Actual speeds may vary up to 50% from

those shown.

Refer to Appendix I, Cutting Speed Charts, for complete

chart data.

4.10 Gouging

WARNING

Be sure the operator is equipped with proper gloves,

clothing, eye and ear protection and that all safety

precautions at the front of this manual have been

followed. Make sure no part of the operator’s body

comes in contact with the workpiece when the torch

is activated.

CAUTIONS

Sparks from plasma gouging can cause damage to

coated, painted or other surfaces such as glass, plas-

tic, and metal.

Check torch parts. The torch parts must correspond

with the type of operation. Refer to Section 4.04,

Torch Parts Selection.

WARNING

Disconnect primary power to the system before

disassembling the torch, leads, or power supply.

A. Gouging Parameters

Gouging performance depends on parameters such

as torch travel speed, current level, lead angle (the

angle between the torch and workpiece), and the dis-

tance between the torch tip and workpiece (standoff).

B. Torch Travel Speed

Optimum torch travel speed for gouging is 20 inches

per minute (0.5 meters per minute) at 3/16 inch (4.7

mm) standoff. Travel speed is dependent on current

setting, lead angle, and mode of operation (hand or

machine torch).

C. Current Setting

Current settings depend on torch travel speed, mode

of operation (hand or machine torch), and the amount

of material to be removed.

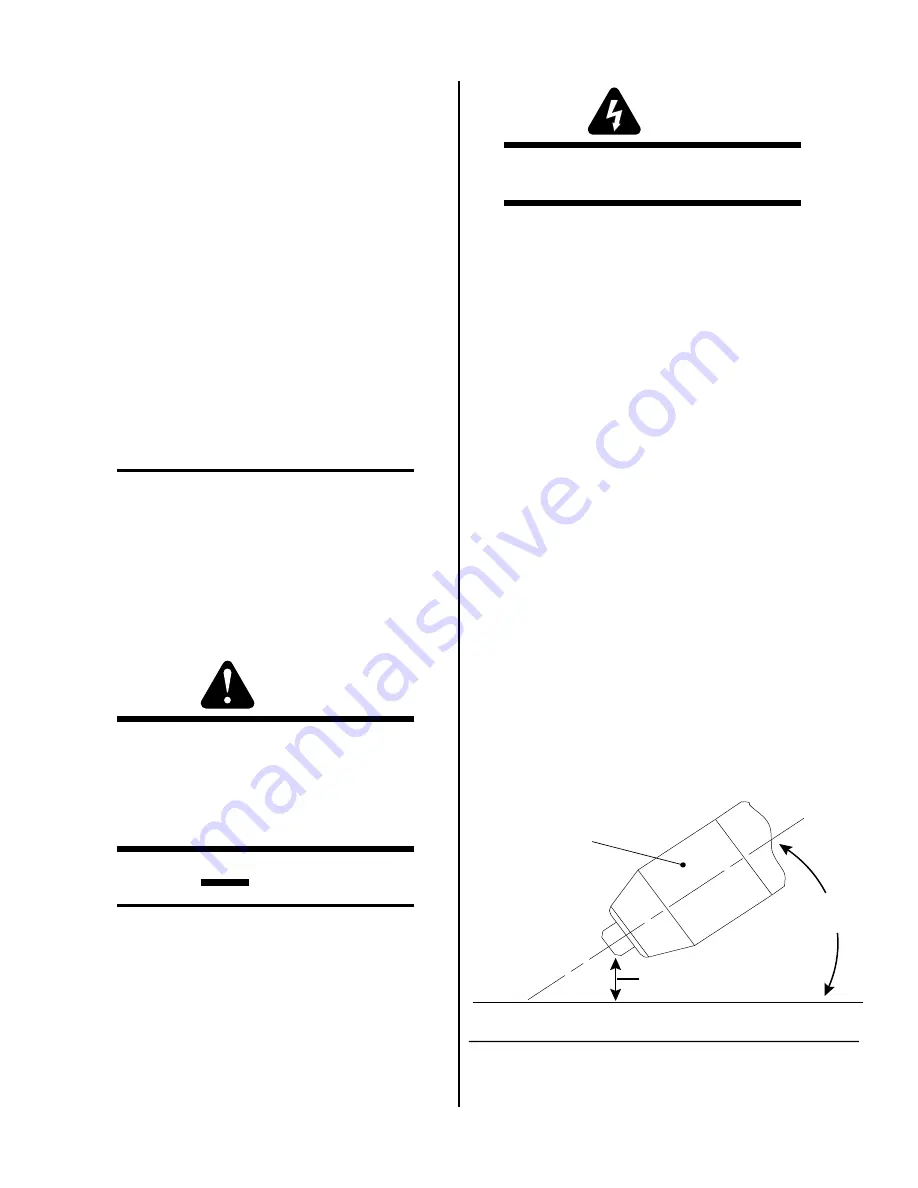

D. Lead Angle

The angle between the torch and workpiece depends

on the output current setting and torch travel speed.

At 70 amps, the recommended lead angle is 35° (refer

to Figure 4-9). At a lead angle greater than 45° the

molten metal will not be blown out of the gouge and

may be blown back onto the torch. If the lead angle is

too small (less than 35°), less material may be removed,

requiring more passes. In some applications, such as

removing welds or working with light metal, this may

be desirable.

35˚

Workpiece

Torch Head

Standoff Height

1/8 - 1/4"

A-00941

Figure 4-9 Gouging Angle and Standoff Distance

Summary of Contents for PCH-100XL

Page 2: ......

Page 6: ......

Page 18: ...INTRODUCTION DESCRIPTION 12 Manual 0 2583...

Page 22: ...INSTALLATION PROCEDURES 16 Manual 0 2583...

Page 38: ...SERVICE 32 Manual 0 2583...