Operating Manual 0-2682

19

DRAG-GUN Plasma Cutter

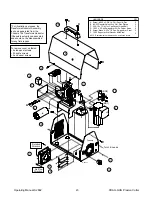

Torch Head Assembly

Electrode

Tip

Standard

Shield Cup

Gas

Distributor

PCH-10

A-02007

Figure 6-2 Consumable Torch Parts

2. Remove the tip. Check for excessive wear (indicated

by an elongated or oversized orifice). Replace the tip

if necessary.

NOTE

The following may also indicate a worn torch tip:

• reduced speed

• voltage drop

• crooked cut

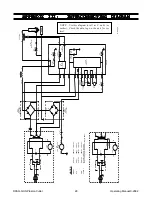

3. Remove the electrode. Refer to Figure 6-3 and check

the electrode for excessive wear. The face of the elec-

trode should not be recessed more than 1/8" (3.2 mm).

If the electrode is worn beyond this point it must be

replaced.

New Electrode

Worn Electrode

A-01270

;

Figure 6-3 Electrode Wear

4. Install the electrode, gas distributor, tip, and shield

cup in the torch body.

CAUTION

Do not overtighten the shield cup.

5. Hand tighten the shield cup using a slight twisting

motion until it is properly seated on the torch head. If

resistance is felt when installing the cup, check the

threads and parts configuration before proceeding.

7.0 PARTS

7.0 PARTS

7.0 PARTS

7.0 PARTS

7.0 PARTS

R E P L A C E M E N T

R E P L A C E M E N T

R E P L A C E M E N T

R E P L A C E M E N T

R E P L A C E M E N T

NOTE

All major parts troubleshooting, repairs, or parts

replacement should only be conducted by a quali-

fied service technician. All repairs are subject to

warranty - tampered parts may void warranty.

WARNING

Disconnect primary power to the system before dis-

assembling the torch & leads, or power supply.

7.1 Torch & Leads Replacement

7.1 Torch & Leads Replacement

7.1 Torch & Leads Replacement

7.1 Torch & Leads Replacement

7.1 Torch & Leads Replacement

NOTE

Prior to removing leads, note all leads connections

inside the unit.

To remove the leads from the unit:

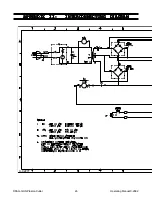

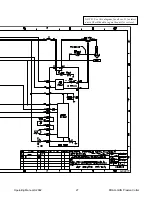

1. Disconnect the following torch lead connections in-

side the unit (see Appendix I):

a. 2-pin Connector

b. Faston Connector to Resistor (red)

c. Faston Connector to CD Coil (white)

2. Loosen the 90° nylon fitting nut and remove the brass

lead fitting. Remove the torch leads from unit. (Cut

lead if necessary).

3. Remove 90° nylon fitting from unit Air Compressor.

(You may need to pull the sheet metal back slightly to

do this.)

To install replacement leads:

4. Remove the securing nut from the strain relief sup-

plied on the end of the replacement torch leads.

5. Feed the end of the replacement torch lead through

the hole in the front panel.

6. Tighten the strain relief and securing nut against the

sheet metal, allowing approximately 1 inch between

the end of the lead and the strain relief nut.

7. Apply teflon thread sealant to the threads of the re-

placement 90° nylon fitting and install in correct ori-

entation as shown in Appendix I.

Summary of Contents for Drag-gun

Page 2: ......