page 33

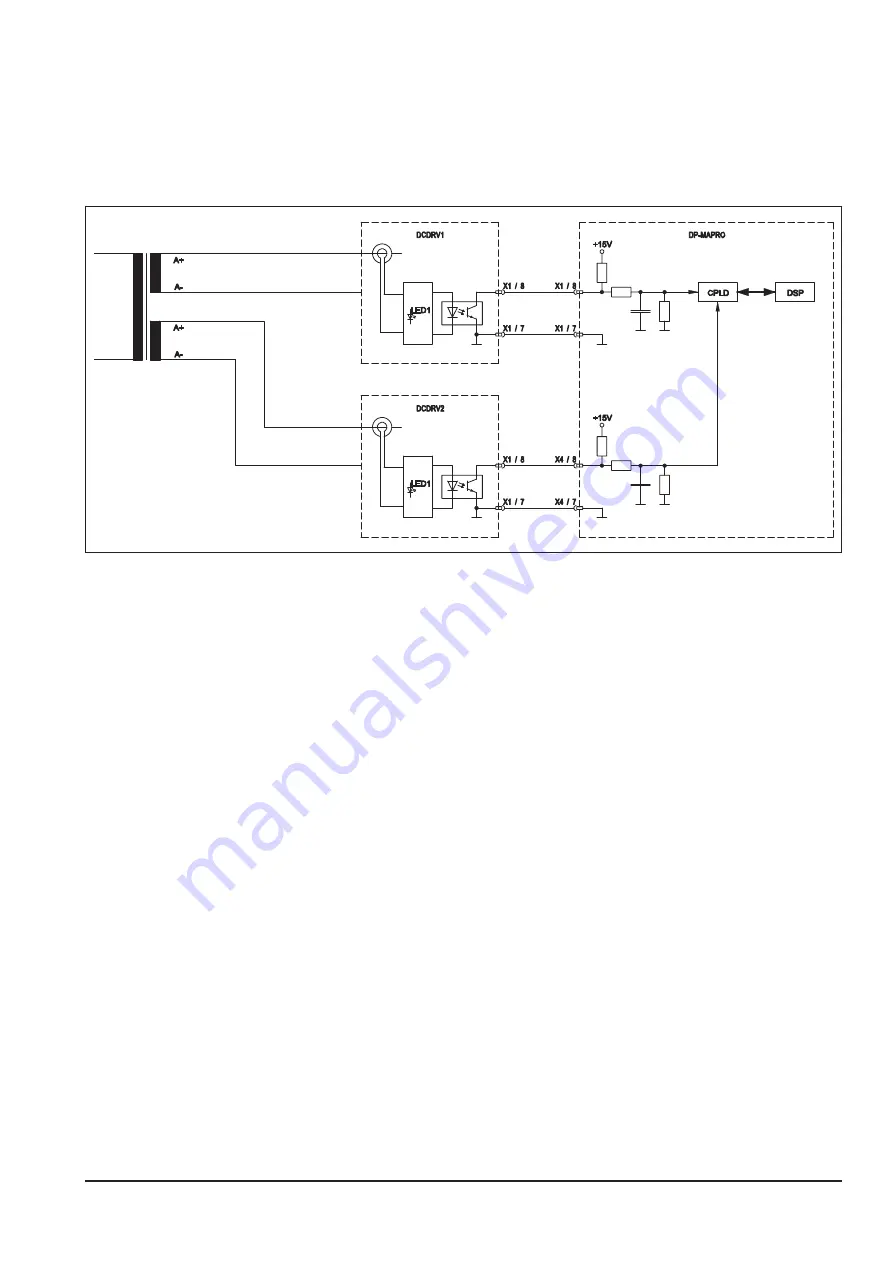

Monitoring primary current

The input current of the power units is monitored at the DCDRV pcb. The current is measured with an internal

current sensor, located on the pcb.As soon as the current is exceeding the maximum value, the CPLD (= Complex

Programmable Logic Device) shuts down the power unit immediately. At the 400SP and 500SP, the weld energy is

generated with two power units at the same time. The 320SP has only one power unit.

Schematic

If power unit 1 draws too much current, the machine will stop and displays

E16

(primary overcurrent protection1).

If power unit 2 draws too much current, the machine will stop and displays

E24

(primary overcurrent protection2).

For example:

E16

(primary overcurrent protection1)

possible reasons could be:

power unit 1 is broken (hardware defect, like broken MOSFET)

-

power unit 2 is not active (if driver signals for the second power unit are missing or the DCDRV pcb of power

-

unit 2 is malfunctioning)

In this case power unit 1 has to generate all the weld energy by itself. Which is possible to a certain amount of

power (200A to 250A) but beyond that, the unit will stop with

E16

malfunction at DCDRV pcb of power unit 1 (e.g. optocoupler output malfunction)

-

bad

fl

at ribbon cables between MAPRO pcb and power units

-

There is a simple way to

fi

nd out if the power unit itself is bad or not (only possible at 400SP or 500SP):

exchange the

fl

at ribbon cables at the MAPRO pcb against each other (connectors X1 and X4) so that power

unit 1 becomes power unit 2 and vice versa. If the machine now shuts down with

E24

(Overcurrent protection 2)

instead of

E16

, the power unit itself is faulty.

If the

E16

should still remain, it is very likely that the MAPRO pcb is faulty.

Summary of Contents for POWERMASTER 320SP

Page 1: ...Service Manual PowerMaster 320SP 400SP 500 SP 999 9997 9 97...

Page 38: ...page 38 Inside Diagram Diodes...

Page 39: ...page 39...

Page 40: ......