LYCOMING OPERATOR’S MANUAL

SECTION 5

O-360 AND ASSOCIATED MODELS

MAINTENANCE PROCEDURES

(7) Hold the magneto in this position and install gasket and magnetos. Secure with clamps, washers

and nuts tightened only finger tight.

(8) Using a battery powered timing light, attach one positive lead to left switch terminal, one positive

lead to right switch terminal and the ground lead to the magneto housing.

(9) Turn the entire magneto in direction of rotation until the timing light comes on, then slowly turn

it in the opposite direction until the light goes out. Bring the magneto backslowly until the light

just comes on.

(10) Back off the crankshaft a few degrees, the timing lights should go out. Bring the crankshaft

slowly backin direction of normal rotation until the lights just come on. Both lights should go on

2°of No. 1 engine firing position.

NOTE

Some timing lights operate in the reverse manner as described. The light comes on when the

breaker points open. Check your timing light instructions.

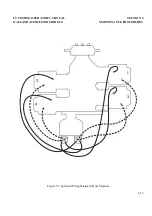

c. Internal Timing – Dual Magneto –

Checkthe magneto internal timing and breaker synchronization in

the following manner.

(1)

Main Breakers –

Connect the timing light negative lead to any unpainted surface of the magneto.

Connect one positive lead to the left main breaker terminal and the second positive lead to the

right main breaker terminal.

(2) Backthe engine up a few degrees and again bump forward toward number one cylinder firing

position while observing timing lights. Both lights should go out to indicate opening of the main

breakers when the timing pointer is indicating within

the width of the L or R mark. If breaker

timing is incorrect, loosen breaker screws and correct. Retorque breaker screws to 20-25 in.-lbs.

(3)

Retard Breaker –

Remove timing light leads from the main breaker terminals. Attach one

positive lead to retard breaker terminal, and second positive lead to the tachometer breaker

terminal, if used.

(4) Backthe engine up a few degrees and again bump forward toward number one cylinder firing

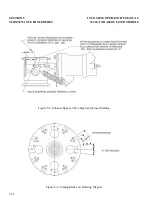

position until pointer is aligned with 15°retard timing mark. See Figure 5-6. Retard breaker

should just open at this position.

(5) If retard timing is not correct, loosen cam securing screw and turn the retard breaker cam as

required to make retard breaker open per paragraph c (4). Retorque cam screw to 16-20 in.-lbs.

(6) Observe the tachometer breaker is opened by the cam lobe. No synchronization of this breaker is

required.

(7) Check action of impulse coupling (D-2000/3000 series only). With the ignition switch off

observe breaker cam end of rotor while manually cranking engine through a firing sequence.

Rotor should alternately stop and then (with an audible snap) be rotated rapidly through a retard

firing position.

5-3