Page 8

CL-B101D40RPM(d0097) manual

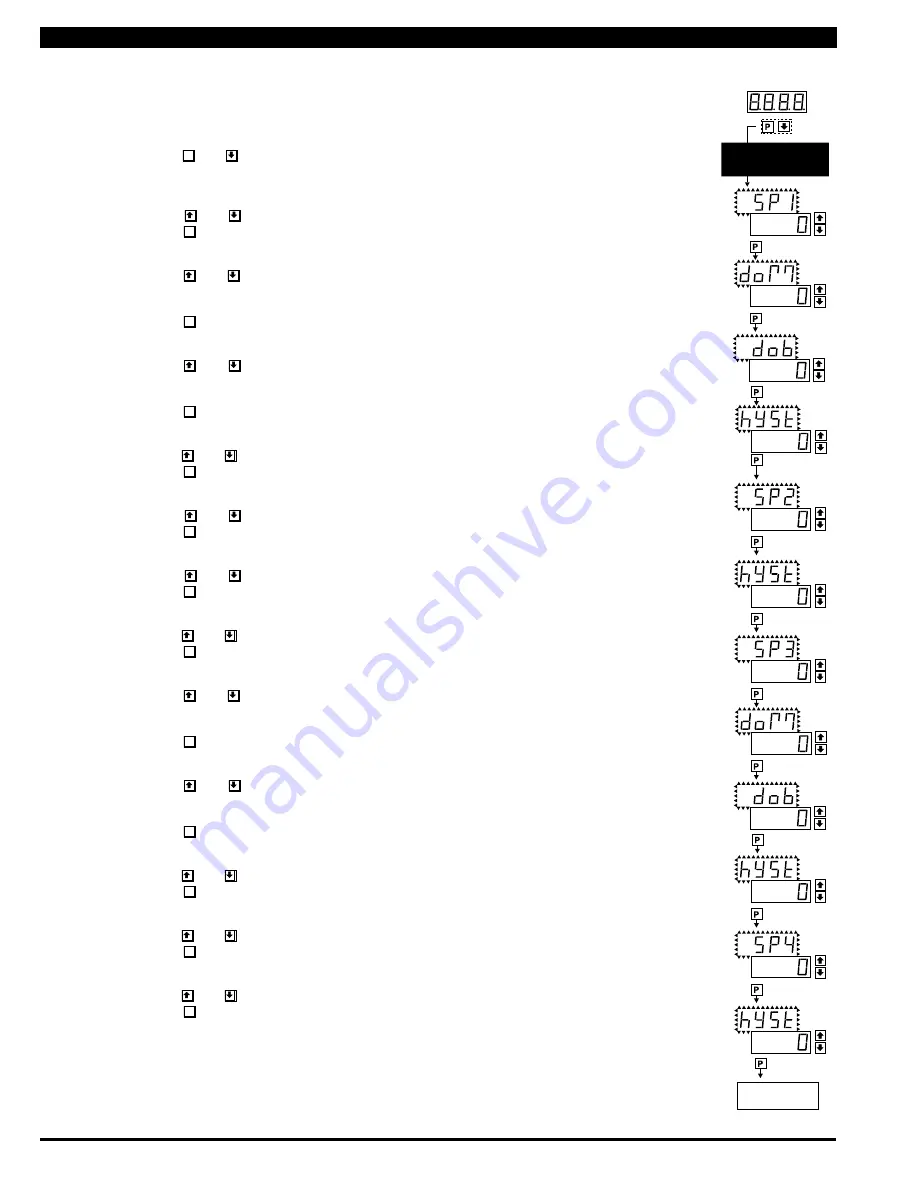

Operational Display

SETPOINT SETTING

AND RELAY

CONFIGURATION MODE

STEP A

STEP B

STEP C

STEP D

STEP E

STEP F

STEP G

STEP H

STEP I

STEP J

STEP K

STEP L

STEP M

To Step N of Setpoint

Setting and Relay

Configuration Page 9

0 to 9999

seconds

0 to 9999

seconds

0 to 9999

seconds

0 to 9999

seconds

The following programming steps are required to enter the setpoint values and configure the relay functions

in a meter with four relays using four setpoints. Generally if less than four relays are installed, the setpoints

without relays are operational in software for tri-color control or display only purposes. To remove unwanted

setpoint indications, set them to 9999 or -1999 depending on the relay activation mode selected.

STEP A Enter the Setpoint Mode

1) Press the

P

and buttons at the same time. Display toggles between [SP1] and the previous

SP1 setting.

STEP B Set Setpoint 1 [SP1]

1) Using the and buttons, adjust the display to the desired SP1 value.

2) Press the

P

button. Display toggles between [doM] and the previous [doM] setting.

STEP C Set the SP1 Delay-on-Make [doM] Delay Time Setting

1)

Using the and buttons, adjust the display to the desired [doM] value (0 to 9999 seconds).

The reading must continuously remain in an alarm condition until this delay time has elapsed before

the relay will make contact (energize).

2) Press the

P

button. Display toggles between [dob] and the previous [dob] setting.

STEP D Set the SP1 Delay-on-Break [dob] Delay Time Setting

1)

Using the and buttons, adjust the display to the desired [dob] value (0 to 9999 seconds).

The reading must continuously remain in a non-alarm condition until this delay time has elapsed

before the relay will break contact (de-energize).

2) Press the

P

button. Display toggles between [hYSt] and the previous [hYSt] setting.

STEP E Set the Hysteresis [hYSt] Setting for Setpoint 1

1)

Using the and buttons, adjust the display to the desired hysteresis [hYSt] value.

2) Press the

P

button. Display toggles between [SP2] and the previous [SP2] setting.

STEP F Set Setpoint 2 (SP2)

1) Using the and buttons, adjust the display to the desired SP2 value.

2) Press the

P

button. Display toggles between [hySt] and the previous [hySt] setting.

STEP G Set the Hysteresis [hYSt] Setting for Setpoint 2

1) Using the and buttons, adjust the display to the desired hysteresis [hYSt] value.

2) Press the

P

button. Display toggles between [SP3] and the previous [SP3] setting.

STEP H Set Setpoint 3 (SP3)

1)

Using the and buttons, adjust the display to the desired SP3 value.

2) Press the

P

button. Display toggles between [SP3] and the previous [SP3] setting.

STEP I Set the SP3 Delay-on-Make [doM] Delay Time Setting

1) Using the and buttons, adjust the display to the desired [doM] value (0 to 9999 seconds).

The reading must continuously remain in an alarm condition until this delay time has elapsed before

the relay will make contact (energize).

2) Press the

P

button. Display toggles between [dob] and the previous [dob] setting.

STEP J Set the SP3 Delay-on-Break [dob] Delay Time Setting

1)

Using the and buttons, adjust the display to the desired [dob] value (0 to 9999 seconds).

The reading must continuously remain in a non-alarm condition until this delay time has elapsed

before the relay will break contact (de-energize).

2) Press the

P

button. Display toggles between [hYSt] and the previous [hYSt] setting.

STEP K Set the Hysteresis [hYSt] Setting for Setpoint 3

1)

Using the and buttons, adjust the display to the desired hysteresis [hYSt] value

2) Press the

P

button. Display toggles between [SP4] and the previous [SP4] setting.

STEP L Set Setpoint 4 (SP4)

1)

Using the and buttons, adjust the display to the desired SP4 value.

2) Press the

P

button. Display toggles between [hySt] and the previous [hySt] setting.

STEP M Set the Hysteresis [hYSt] Setting for Setpoint 4

1)

Using the and buttons, adjust the display to the desired hysteresis [hYSt] value

2) Press the

P

button. Display toggles between [rLYS] and the previous relay setting.

Please Continue On Next Page.

Setpoint Setting and Relay Configuration Mode