Page 6

CL-B101D40RPM(d0097) manual

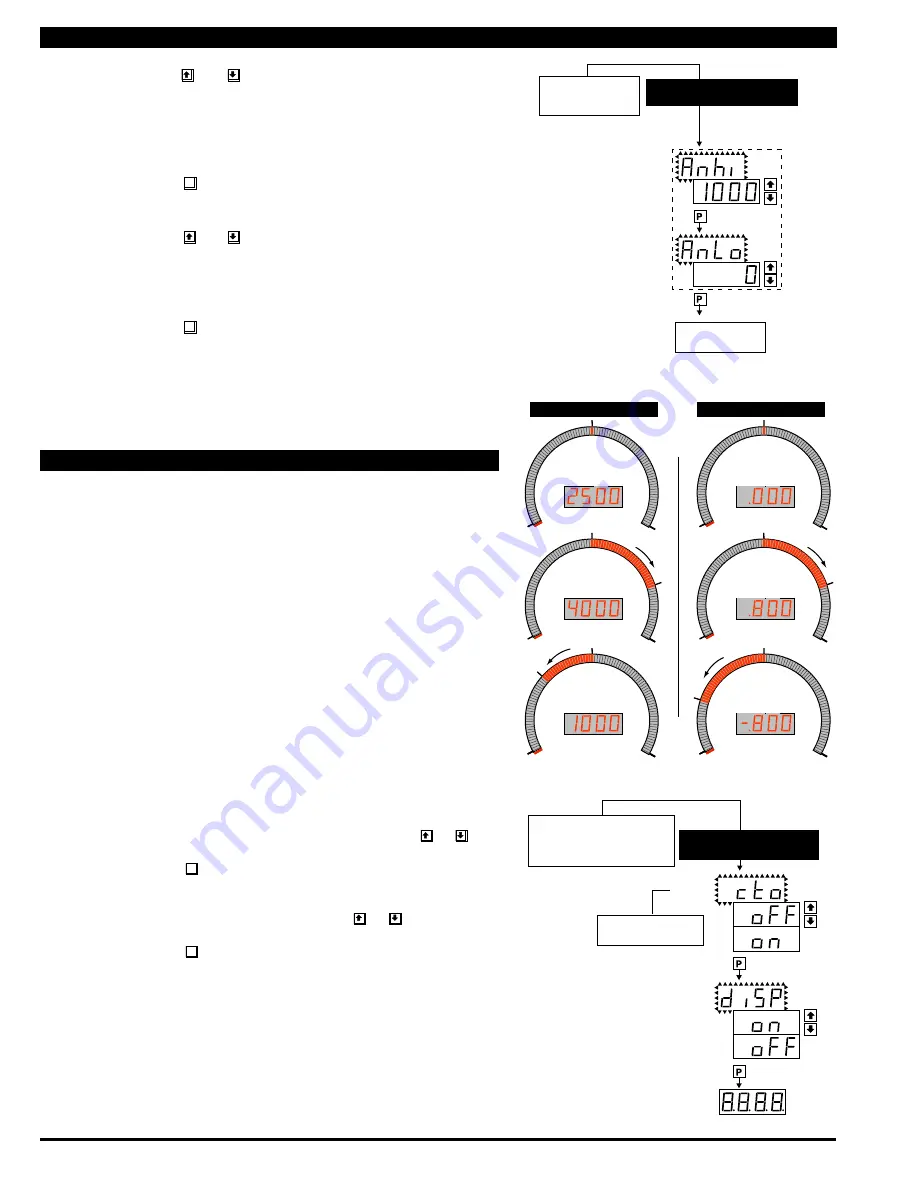

STEP C Selecting the [Anhi] Digital Value for Analog High Output

1) Using the and buttons, adjust the display to the desired

digital value at which the [chi] Calibrated Analog High output will

occur. For digital readings outside the digital span selected, the

analog output will linearly rise above the value set for chi, up to the

maximum analog output capability. However, the analog output will

not go lower than the calibrated value set for cLo (see below).

2) Press the

P

button. Display toggles between [AnLo] and

previous [AnLo] setting.

STEP D Selecting the [AnLo] Digital Value for Analog Low Output

1) Using the and buttons, adjust the display to the desired

digital value at which the [cLo] Calibrated Analog Low output will

occur. For Digital readings outside the Digital Span selected, the

analog output will not go lower than the calibrated value set for

cLo.

2) Press the

P

button. The display toggles between [cto] and

[oFF].

Note:

Any two digital span points from –1999 to 9999 can be selected. The digital

values for [Anhi] analog high and [AnLo] analog low can be reversed to provide a 20 to

4mA output. The digital span selected can be as small as two counts, when using the

analog output to function as a Control or Alarm Driver. Small digital spans will cause

the high resolution 16 bit D to A to increment digitally in stair case steps.

Digital Span Selection for Analog Range Output

Digital Span Selection for Analog Range Output

Bargraph Center Point Display Mode Selection

STEP E Bargraph Center Point Mode Selection (See example above)

1) To select bargraph center point mode, press the or

button. Display changes from [oFF] to [on].

2) Press the

P

button. Display toggles between [diSP] and

[on] or [oFF].

STEP F Digital Display ON/OFF Selection

1) To set the display to [oFF], press the or button.

Display toggles between [diSP] and [oFF].

2) Press the

P

button. The display exits the calibration mode

and returns to the operational display. Only the bargraph

display is on and the digital display is off.

If the digital display is selected to be off, pressing any button to

make programming changes or to view setpoints activates the digital display.

When the procedure is complete, the digital display will then automatically

switch off.

The Display/Bargraph settings are now complete.

Operational Display

STEP E

STEP F

See Example of Bargraph

Center Point Display Mode

Selection Above

From Digital Span Selection

for Analog Range Output Above

or Direct From Digital Span Selection

for Bargraph Display Page 5

if Analog Output Option is Not Present

BARGRAPH CENTER POINT

DISPLAY MODE SELECTION

STEP C

STEP D

This branch will only

appear if the analog

output option is installed

To Bargraph Center

Point Display Mode

Selection Below

From Digital Span

Selection for Bargraph

Display

See Page 5

DIGITAL SPAN SELECTION

FOR ANALOG RANGE OUTPUT

Example of Using the Center Point Bargraph Display Mode

with a Unipolar Input

If the meter's full scale range is set to 5000 counts, the midpoint would

be 2500 counts. If a signal of 2500 counts is applied only one segment at

the 2500 count mark will light up. If a signal of 4000 counts is applied the

segments between the center segment (2500 counts) and the 4000 count

mark light up.

If a signal of 1000 counts is applied, the segments between the center seg-

ment (2500 counts) and the 1000 count mark will light up.

Example of Using the Center Point Bargraph Display Mode

with Bipolar Signal Inputs

The

meter

may also be calibrated to display symmetrical bipolar signals such

as ± 1 V or ± 10 V. When the center point display mode is selected, it will

then function as a center zero meter. When positive signals are applied, the

bar will go up from the center point, and when negative signals are applied,

the bar will go down from the center point.

-1V

+1V

0V

-1V

+1V

0.800

-0.800

0V

-1V

+1V

0V

Center Point

Single Bar Lit

Center Point

As signal

increases

Digital display

Digital display

Center Point

As signal

decreases

Digital display

0

5000

5000

2500

2500

4000

0

5000

2500

1000

0

Center Point

Single Bar Lit

Center Point

As signal

increases

Digital display

Digital display

Center Point

As signal

decreases

Digital display

Unipolar Signal Input

Bipolar Signal Input