Page 7

CL-B101D40RPM(d0097) manual

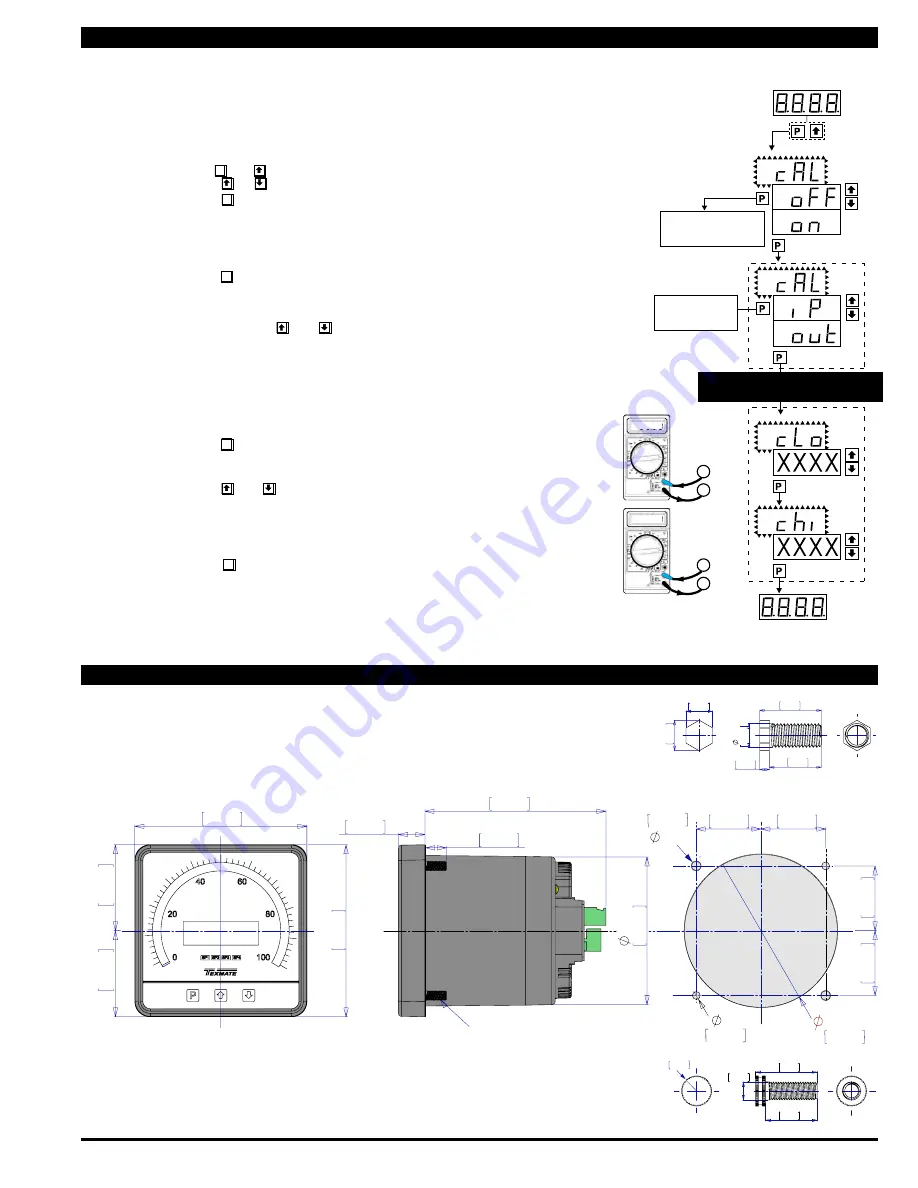

Case Dimensions

Operational Display

Sub-menu

MODE

STEP A

Calibration

Mode

STEP B

Calibration

Mode

STEP E

Calibrate

Analog

Output

Lo

STEP F

Calibrate

Analog

Output

Hi

Will only appear if the analog

output option is installed

To Digital Span Selection

for Bargraph Display

See Page 5

To Two Point Digital

Calibration Mode

See Page 4

Operational Display

TWO POINT ANALOG OUTPUT

RANGE SETTING AND CALIBRATION

+

x

–

x

4.00

+

x

–

x

20.00

Determine if the Analog Output Selection Header is in the 4 to 20mA (0-20mA) position or the 0

to 10VDC position. If necessary, the module may have to be removed and the header position

changed (see Component Layout below).

Note: Always disconnect power from the meter before removing the analog output module to

adjust the mA or Volts output selection header and reinstalling it. When power is reconnected, the

meter’s software will automatically detect the presence or absence of the analog output module.

STEP A Enter the Calibration Mode

1) Press the

P

and buttons at the same time. Display toggles between [cAL] and [oFF].

2) Press the or button. Display changes from [oFF] to [on].

3) Press the

P

button. Display toggles between [cAL] and [out] input calibration.

Note

: If at this point the display skips directly to toggle between Zero and the previous Zero

setting, the software is detecting that the optional analog output hardware is NOT installed.

STEP B

Enter the Two Point Analog [ouT] Output Range Setting and Calibration Mode

1) Press the

P

button. Display toggles between [cLo] and an internal scale factor.

STEP E

Set or Calibrate [cLo] the Low Analog Value of the Analog Output Range

1) Connect a multimeter to analog output pins 17 and 18 (see Rear Panel Pinouts

on page 10). Using the and buttons, adjust the analog output to the desired

low value as measured on the multimeter. cLo may be adjusted to any value from

–0.3 mA to 18 mA (mA output selected) or from –0.6 V to 8 V (volt output selected).

However, the output of cLo must always be less than the value selected for chi. If

a reversed analog output is desired, the values selected to establish the Digital

Span can be reversed (see top of page 6). For digital readings outside the Digital

Span selected, the analog output will not go any lower than the calibrated value set

for cLo. However, the analog output will linearly rise above the value set for chi, up

to the the maximum analog output capability (see chi below).

2) Press the

P

button. Display toggles between [chi] and an internal scale factor.

STEP F

Set or Calibrate [chi] the High Analog Value of the Analog Output Range

1) Using the and buttons, adjust the analog output to the desired high value

as measured on the multimeter display. chi may be adjusted to any value from 18

mA to 24 mA (mA output) or from 8 V to 10.3 V (volt output). However, the value

must be higher than the value selected for cLo. For digital readings outside the

Digital Span selected, the analog output will linearly rise above the value set for chi,

up to the maximum analog output capability.

2) Press the

P

button. The meter exits the calibration mode and returns to the

operational display.

Note:

The analog output range established by the values selected for cLo and chi will occur, auto-

matically scaled, between the two digital values selected for AnHi and AnLo. However, the analog

output can linearly rise above the chi value set for digital readings outside the digital span

selected. See Digital Span Selection on page 6.

Two Point Analog Output Range Setting and Calibration

Two Point Analog Output Range Setting and Calibration

101.60

4.000

42.85

1.687

42.85

1.687

42.85

1.687

42.85

1.687

6.50

0.256

113.79

4.480

113.79

4.480

56.90

2.240

56.90

2.240

17.50

0.689

97.77

3.849

119.70

4.713

13.70

0.539

1/4"-28UNF

Panel Cutout

5.0

0.197

R4

0.157

16.30

0.642

13.70

0.539

4.80

0.189

screw-10-32 UNF

8

0.315

7

0.276

16.30

0.642

13.70

0.539

2.60

0.102

6.32

0.249

screw-1/4”-28 UNF