11

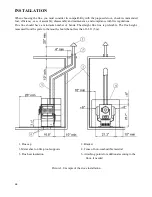

The interior diameter of the flue must be identical to the stove's smoke exhaust. A flue which is too small

may cause draft problems, while a large flue favors the rapid cooling of the gas, deposition of creosote and a

risk of fire.

The height of the flue, measured from the roof, should be:

a) not less than 20” (500 mm) over a flat roof

b) not less than 20” (500 mm) over the ridge of the roof or parapet - when the flue is located within 5 ft (1.5

m) of the ridge or parapet

c) not below the ridge of the roof or parapet - when the flue is located within 5 - 10 ft (1.5 – 3 m) of the

ridge or parapet

d) not below a line, drawn from the ridge down at 10° angle to the horizon, - when the flue is located at a

distance of more than 10 ft (3 m) from the ridge or parapet.

The top of flue should be higher than the roof of adjacent buildings.

It’s recommended to install metal spark catchers with meshes of less than 0.2” (5 mm).

Attention

!

To prevent leakage of smoke into the heated room all the joints between the sections of the

flue and between the flue and the stove must be sealed with a heat-resistant sealant, ensuring

the integrity of flue joints.

When installing the flue through the ceiling it’s necessary to perform cutting for a fire block. The fire block

must exceed the thickness of the ceiling by 2.75” (70 mm). You should not rest or rigidly connect the fire

block with building elements.

Spacing between the ceiling and the fire block should be filled with non-combustible materials (expanded

clay, slag, basalt wool, sand etc.).

The distance from the outer surface of the flue without insulation to the rafters, roof battens and other parts

of the roof of combustible and semi-combustible materials should be not less than 10” (250 mm). And for a

non-combustible flue insulation – not less than 5” (130 mm).

The space between the flue and roof structures of combustible and semi-combustible materials should be

covered with non-combustible roofing materials.

It is not recommended to incline the axis of the flue from the vertical by more than 45°.

The distance between the vertical axis of the stove’s flue collector and the vertical axis of the flue should not

be more than 3.2 ft (1 m).

It is strictly forbidden to perform non-separable connections of the stove with a flue pipe.

Caution

!

The section of flue, located in the zone of sub-zero temperatures (32° F), must always be

insulated with materials, which can withstand temperatures up to +750° F (+400° C)

Make sure that the temperature of flue walls in the zone of sub-zero temperatures is at least 210° F (100° C).

This will prevent condensation of moisture, from flue gases.

For the flue line the manufacturer recommends to use a modular thin-walled stainless steel flue pipe with a

diameter of 2.5” (63 mm). We highly recommend to use finished heat-resistant flue pipes “sandwich”, which

can withstand the temperatures up to 850—1000°F (450—550°С).

They are efficient, durable and require minimal labor for installation and operation Flue pipes are connected

in the following way: «the lower one goes inside the top one».In this case, an additional draft will be created

and it will not allow the leakage of smoke through the joints of the flue system into the room.