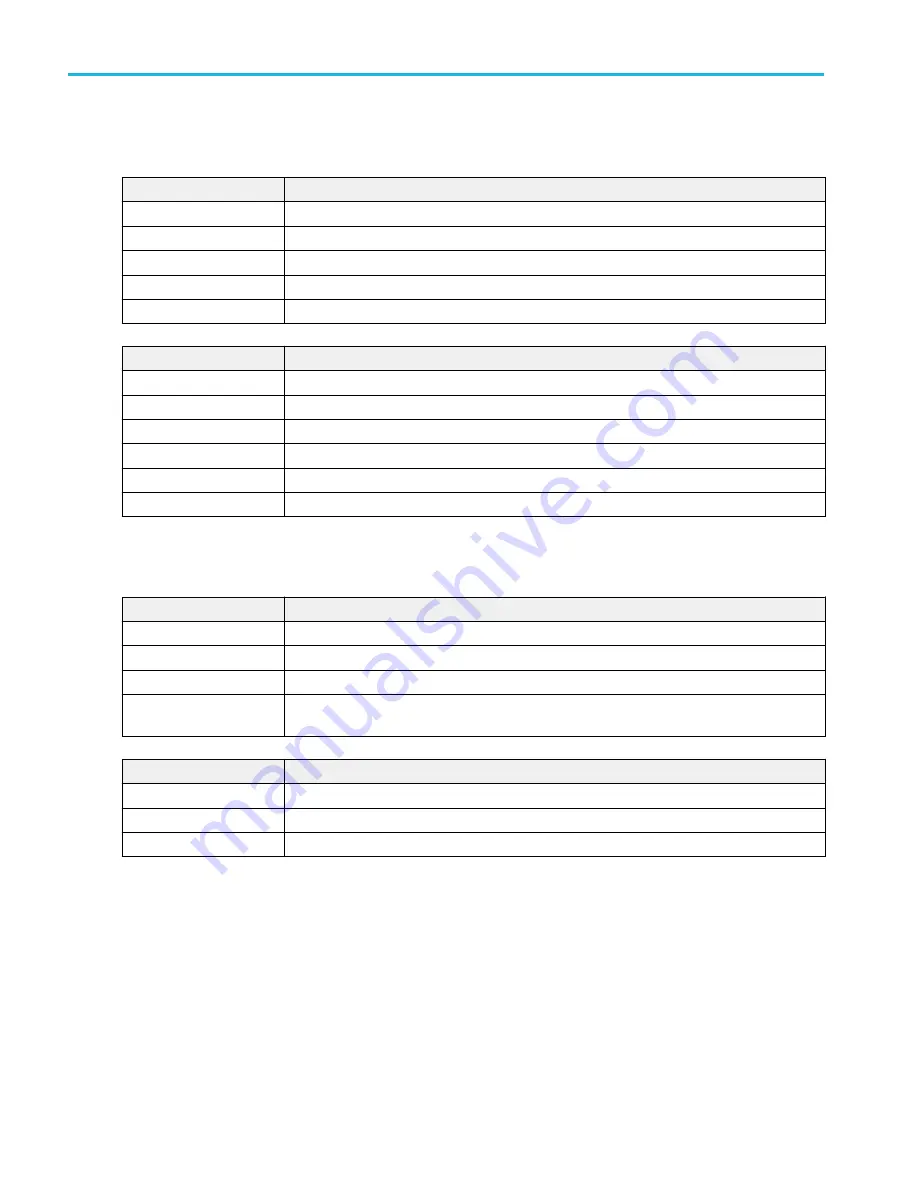

Models

AWG70001B

10 bit, 2 GSamples record length, 1-channel arbitrary waveform generator

AWG70000-150

50 Gs/s Sample Rate

AWG70000-MEM

Waveform record length expansion to 32 GSamples

AWG70001B-AC

Adds a single-ended AC coupled output connector with additional amplification and attenuation

AWG70001B-SEQ

Adds Sequencing

AWG70000-STRID

Adds Streaming Waveform ID (Streaming WID) (requires AWG70001B-SEQ)

AWG70002B

10 bit, 2 GSamples record length, 2-channel arbitrary waveform generator

AWG70000-208

8 Gs/s Sample Rate

AWG70000-216

16 Gs/s Sample Rate

AWG70000-225

25 Gs/s Sample Rate

AWG70000-MEM

Waveform record length expansion to 16 GSamples per channel

AWG70002B-SEQ

Adds Sequencing

AWG70000-STRID

Adds Streaming Waveform ID (Streaming WID) (requires AWG70002B-SEQ)

Product upgrades

AWG70001B upgrades

Description

AWG70001B STRID

Adds Streaming Waveform ID (Streaming WID) (requires AWG70001B-SEQ)

AWG70001B SEQ

Adds sequencing

AWG701BUP SSD

Provides an additional (or replacement) preprogrammed solid state drive

AWG701BUP AC

Adds a single-ended AC coupled output connector with additional amplification and attenuation

(factory installation only)

AWG70002B upgrades

Description

AWG70002B STRID

Adds Streaming Waveform ID (Streaming WID) (requires AWG70002B-SEQ)

AWG70002B SEQ

Adds sequencing

AWG702BUP SSD

Provides an additional (or replacement) preprogrammed solid state drive

Install the instrument

4

AWG70000B Series Installation and Safety Instructions

Summary of Contents for AWG70001B

Page 2: ......

Page 6: ......

Page 12: ...Important safety information vi AWG70000B Series Installation and Safety Instructions ...

Page 16: ...Compliance Information x AWG70000B Series Installation and Safety Instructions ...

Page 32: ...Install the instrument 16 AWG70000B Series Installation and Safety Instructions ...