20

Component List of Brake Control Cabinet

NO Label

Description

Specification

Qty.

1 BOX

Electrical brake control cabinet

470mm x 320mm

1

2 NFB1

No fuse breaker

20A/2P/300VAC

1

3 NFB2,NFB3 No fuse breaker

50A/3P/600VAC

2

4 RY1~RY6

Electromagnetic Brake main relay

35A(above)/220VAC(main contact)

drive voltage 220V

6

5 RY7,RY8

Electromagnetic Brake aux. relay

5A(above)/220VAC(main contact)

drive voltage 12Vdc

2

6 TB

Terminal block

12x2P 600V/main contact 30A (above)

1

7 WH

Wattmeter

220V/10(30)A/(50/60HZ)

1

8 C1,C2

AC capacitance

X capacitor/0.22uF/275VAC

2

9 R1~R3

Power resistor 3

Ω

/1KW 3

10 PS

DC power supply

Input 200V~260V/Output 12Vdc; 1A

(above)

1

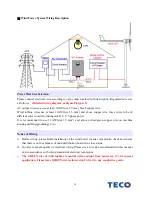

Installation Procedure of Electrical Wire Brake control cabinet

(1)

When wiring, it is not necessary to open top cover of wind power inverter, ensure wiring is fixed

well and there is no danger of coming loose.

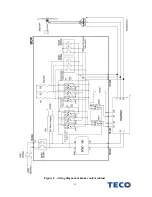

(2)

As shown on Figure 8, there are nine wires from wind power inverter, they are

R,S,T,L,N(12AWG), and al, a2(12AWG) short brake signal contact and b1,b2(12AWG)

resistor brake contact.

(3)

Wind turbine output R,S,T wire is connected respectively to manual brake switch, automatic

brake switch and three relays’ C contact then finally connected to wind power inverter.

(The

GREEN wire of wind turbine is neutral wiring output from generator, it’s for special

application. Please leave GREEN wire isolated, don’t wire it to any conductive goods.)

(4)

The terminal block (European type) as attachment is connected respectively to a1, a2, b1, b2

contact.

(5)

a1 and a2 connected to signal of automatic short circuit brake switch, b1 and b2 connected to

signal of automatic resistor brake switch.

(6)

AC output is a spiral exclusive socket connected to domestic utility distribution board, then

connected to utility through bi-directional wattmeter.

(7)

Grounding wire (PE) connected to wind power inverter and system grounding, please avoid

connecting grounding wire with main line and ensure grounding is properly done.

(8)

When adopting the third kind grounding, grounding resistor must be less than 10

Ω

.

(9)

Brake Resistor consists of three 3

Ω

/1KW; Y connection is connected to three relay b contact