GB

16

6. MAINTENANCE

W

W

W

W

A

A

A

A

R

R

R

R

N

N

N

N

II

II

N

N

N

N

G

G

G

G

!!

!!

!!

!!

!!

!!

THIS PROCEDURE MAY ONLY BE DONE

BY AN AUTHORISED TECNOMAC

INSTALLATION TECHNICIAN

Regular maintenance is limited to descaling or

replacing the boiler, together with annual

cleaning (generally done before seasonal

close-down).

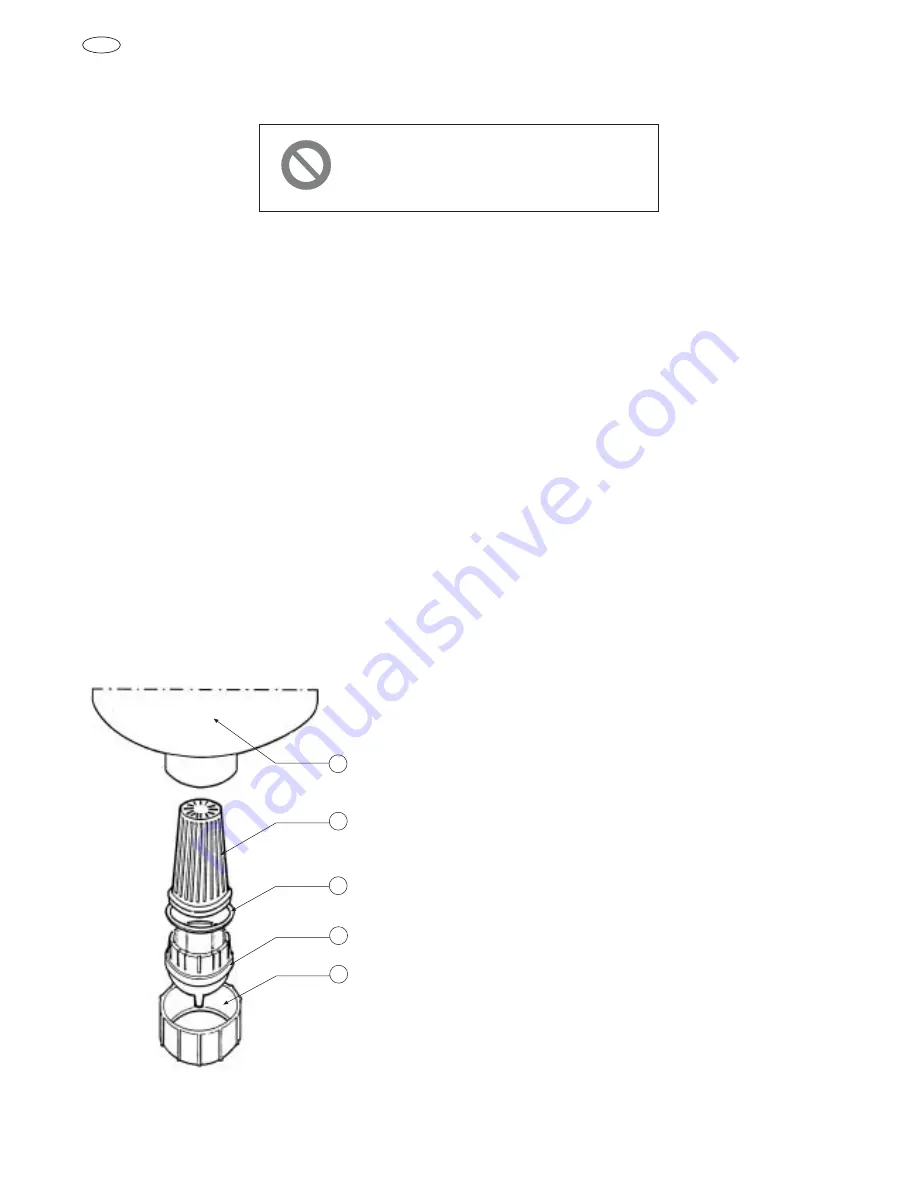

CYLINDER BOILER CLEANING

AND REPLACEMENT

This is necessary when scale on the active sur-

faces of the electrodes prevents the sufficient

passage of electrical current (alarms E08 and

E06).

To dismantle the cylinder boiler:

– drain water completely, by pressing MANUAL

DRAIN button 11) on the control panel;

– cut of power to the equipment by means of

switch or line fuses;

– remove steam pipe from the boiler;

– disconnect wiring to main electrodes and

unplug light level electrodes;

– unscrew fixing knob to free cylinder, lift boiler

to remove. The boiler may generally be used

again after descaling. Unscrew ring nut (see

figure) and extract bottom filter. Remove

scale and calcareous deposits under a jet of

water and clean grids mechanically or chem-

ically with a commercially available cleaner.

When electrode wear is such that regenera-

tion is insufficient, the boiler must be

replaced. Exchange only involves the body

of the boiler and the gasket. The ring nut,

connection piece and filer do not deteriorate

with use.

Reassemble the boiler in reserve sequence,

after, checking and if necessary the washer

between the threaded connection and the dis-

charge group.

CLEANING AND SEASONAL

CLOSE-DOWN

Annually, or before summer close-down,

inspect and clean the systems. Drain water

from the boiler by pressing the MANUAL

DRAIN pushbutton 11) on the control panel

and cutting off power.

The following is Recommended:

– dismantle and wash water intake valve, and

check that intake filter is clean;

– dismantle drain group, cleaning conduits and

nozzles and removing and solids from the

base of the syphon;

– inspect water intake, drain, steam and con-

densation pipes, and replace them it they are

worn out or fragile.

5

4

1

3

2

1. RING NUT

2. CONNECTION PIECE

3. GASKET

4. FILTER

5. CYLINDER BOILER