7

/

24

2.8

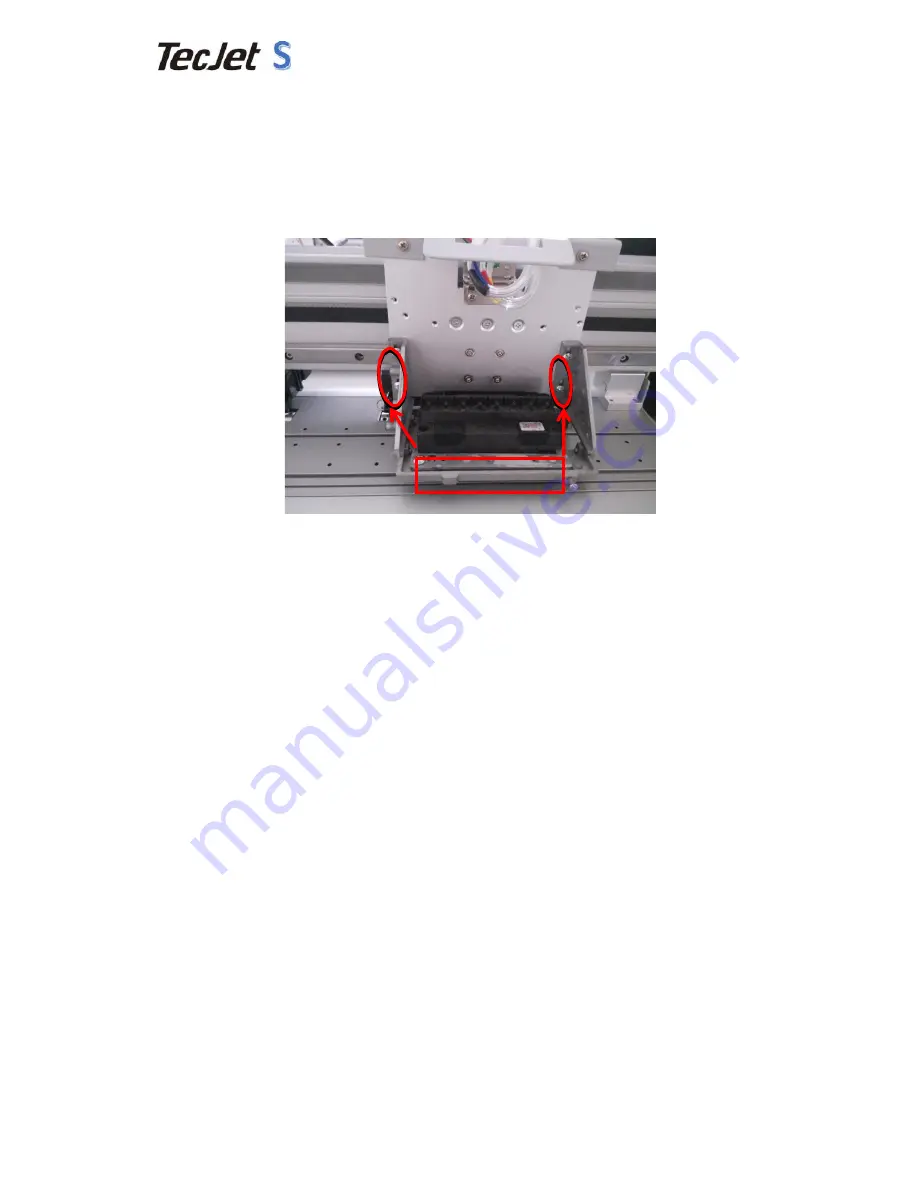

Distance between Printhead and Media

Printhead base can be adjusted according to Media thickness. The best distance

between printhead and media is 1.5mm, not more than 2mm. Media should be

smooth. Adjust the M4X8 bolts as image shows, the distance will be changed

accordingly.(Example at DX5 Head)

2.9

Ink Installation

1)

Keep ink out of the reach of Children. If it enters your eyes or splash on your

clothes, please flush with plenty of water.

2)

Clean ink tube with our clean flush.

3)

The temperature of ink should be better kept between 18

℃

—28

℃

.

4)

After open the inks, it should not be kept for a long time. Please use it ASAP.

5)

Don’t shake the ink bottles. Don’t pollute environment by throwing ink, ink

bottle at your will.

6)

Add ink as image below shows. Connect ink tube as the image shows.

M4X8 Bolt

Summary of Contents for S Series

Page 12: ...9 24 DX5 1 DX5 2 DX7 1 DX7 2 XP600 1 XP600 2 ...

Page 15: ...12 24 For 5113 printhead it s the order as below ...

Page 17: ...11 24 For 5113 printhead it should be connected as below ...

Page 27: ...24 24 7 Control panel 8 Carriage connection instruction Mainboard ...

Page 30: ...27 24 ...

Page 34: ...21 24 4 11 Step Eleven Press Set As Default Printer and press OK then finish ...