21

13 MAINTENANCE

The TS6500 Mixer is designed and built to be relatively maintenance

free. To assure trouble free operation, the following

recommendations should be followed:

1. Make certain the air supply is clean and dry.

2. Avoid connecting the unit to excessive moisture or solvent

saturation.

3. Use only Amyl Alcohol to clean outside surface of the main

housing.

4. Use only soft cloth to clean the LCD.

5. Clean the injection rod regularly with cleaning solvent

6. Clean the tray regularly with cleaning solvent

14 LIMITED WARRANTY

OK International warrants this product to the original purchaser for a

period of one (1) year from date of purchase to be free from material

and workmanship defects but not normal wear-and-tear, abuse and

faulty installation.

Defective product or subassembly and

components under warranty will be repaired or replaced (at OK

International's

option) free of charge. Customer with defective

product under warranty must contact the nearest OK International

office or distributor to secure a return authorization prior to shipping

the product to the assigned OK International authorized service

center. For nearest OK International office or distributor contact

information, please visit www.okinternational.com. OK International

reserves the right to make engineering product changes without

notice.

22

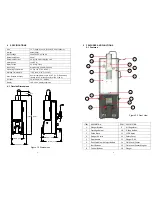

15 APPENDIX

15.1 Spare Parts List

ITEM PART

NUMBER

DESCRIPTION

QTY

1

7091-9010

CARTRIDGE HOLDER ASSEMBLY, 2.5oz/6oz/8oz

1

7091-9030

CARTRIDGE HOLDER ASSEMBLY, 20 oz

1

2

7091-9040

PLUNGER ASSEMBLY, 2.5oz/6oz/8oz

1

7091-9060

PLUNGER ASSEMBLY, 20 oz

1

3

7091-0420

HOLDER, PLUNGER ASSEMBLY

1

4 7091-0120

SPINDLE

EXTENSION

1

5

7091-0530

WRENCH, THIN HEAD, 19mm

1

6

7091-9080

AIR FILER ASSEMBLY

(Filter only = TSD800-6)

1

7 6002-0703

POWER

CORD

1

8 7091-0430

TRAY

1

9

5100-0079

START PUSH BUTTON

1

10 TSD500-29

AIR

REGULATOR

1

11 5100-0078

E-STOP

SWITCH

1

12 7091-0510

LCD

COVER

1

13 7091-9070

SPINDLE

ASSEMBLY

1

14 7091-0430

SAFTY

DOOR

1

15 5100-0077

INTERLOCK

SWITCH

1

Figure 18.0 Main Assemly