9

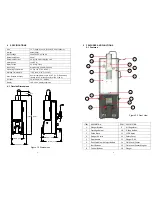

5.2 Operation Function

DESCRIPTION FUNCTION

1 Plunger

Bracket

•

Holds plunger assembly when not in use

2 Cartridge

Holder

•

Holds cartridge kit

•

Operates with the plunger assembly and

guide block to drive the cartridge up and

down for mixing

3 Guide

Block

•

Operates with the plunger assembly and

cartridge holder to drive the cartridge up

and down for mixing

4

Air Plunger Inlet

•

Provides air to plunger

5 Door

Handle

•

Secures cover and disengages door

6

Drive Spindle with

Injection Rod

•

Rotates mix rods during mix cycle

•

Injects the hardener into the resin

7

Start Buttons

(Green)

•

Starts the unit

•

Press green buttons simultaneously to

start

8 Control

Buttons

•

Input buttons (see Fig. 5)

9 Air

Regulator

•

Regulate the air pressure to the unit

10

Emergency Stop

button (Red)

•

Stops the Unit in an Emergency

•

Press to Engage

•

“E-Stop!” will be displayed,

•

To reset, rotate the E-Stop knob a

quarter turn clockwise

11 LCD

Display

•

Displays unit status, operation and error

messages.

12

Protective (Safety)

Cover

•

Protect operators when machine in use

13 Plunger

Disk

•

Part or Plunger Assembly

14 Fluid Level Sensor

•

Senses the fluid level at the top of the

cartridge

10

15

Fluid Level

Magnet

•

Work with Fluid Level Sensor

16 Plunger

Assembly

•

Locks cartridge in place

•

Applies steady pressure to prevent air

entrapment

17

Flow Control; Main

Cylinder

•

Controls the speed of the Main Cylinder

•

Rotate the flow control screw clockwise

to increase the speed.

•

Rotate the flow control screw

counterclockwise to decrease the speed

18

Flow Control;

Injection Rod

•

Controls the speed of the injection rod

•

Rotate the flow control screw clockwise

to increase the speed.

•

Rotate the flow control screw

counterclockwise to decrease the speed

19

Voltage Select

Switch

•

Select 115V or 230V

20

Power Input

Socket with Fuse

Box

•

Input power connection

21 Air

Filter

•

Provide air filtration

22 Wrench

•

Use to install Air filter assembly and

Drive spindle assembly

23

Accessories

Bracket

•

To hold wrench or other accessories

24

Cartridge Holder

Bracket

•

To hold extra Cartridge Holder