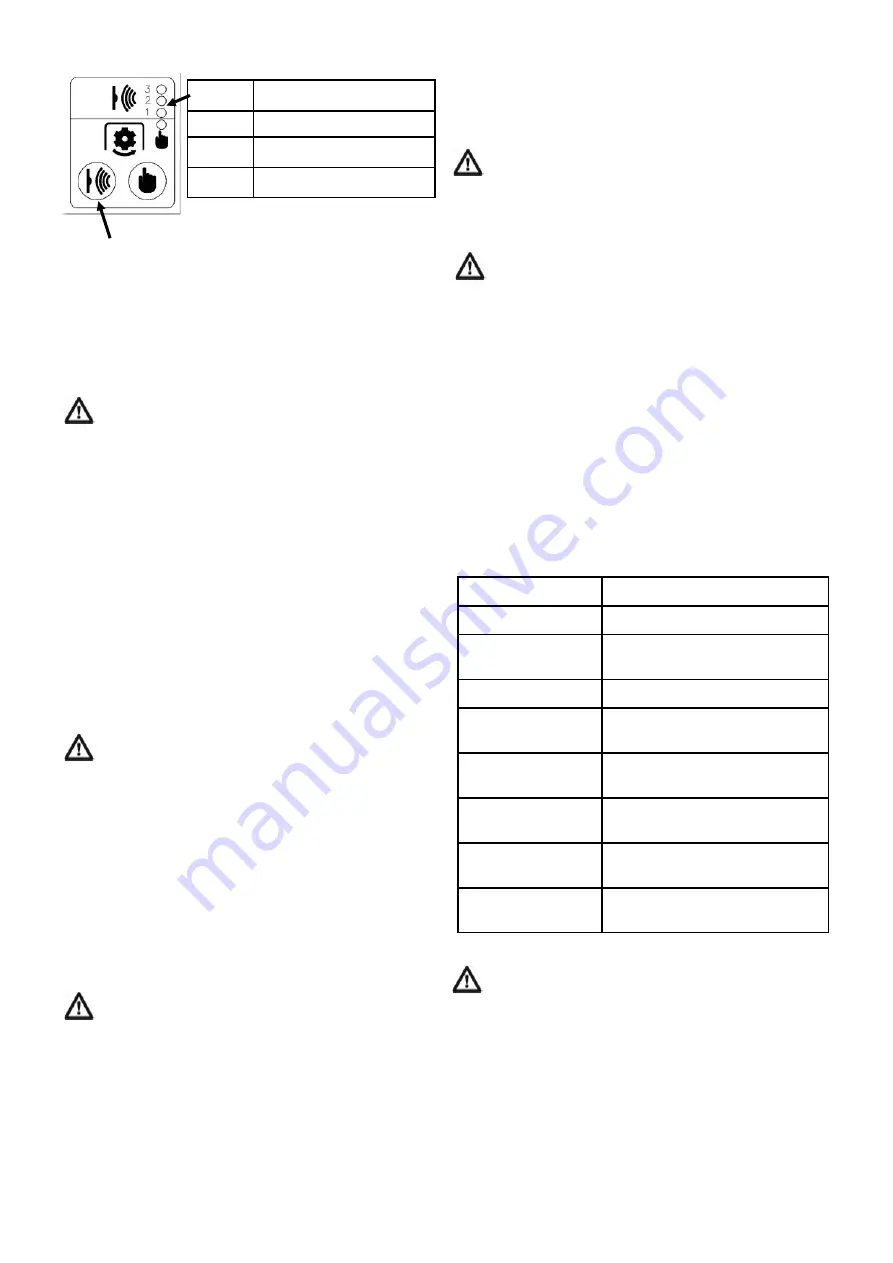

The mode is switched by repeatedly pressing the

automatic bale chamber control button.

However the optimum setting will vary depending on

material moisture content and density.

As the milled material builds up beneath the conveyor

discharge point it may be necessary to stop milling and

reposition the machine if the material can not be moved

away by the loading vehicle.

When it is necessary to stop milling part way

through a bale, always stop the bale chamber

rotation and put it in reverse for a few seconds

before stopping the mill rotor. This allows the material in

the area around the mill rotor to be removed by the

conveyor. Failure to do this may result in a blockage

when the machine is re-started.

To stop the machine without the control desk press the

auxiliary stop button on the side of the machine, this will

first stop the bale chamber rotation. After a short delay to

make sure the material is removed from the mill rotor

housing the conveyor will stop. The mill rotor will then

have to be stopped by disengaging the PTO drive in the

tractor driving the machine.

Occasionally materials may lodge against the side of the

bale chamber and not feed down into the mill. If this

occurs reverse the rotation of the bale chamber for 1 to 2

turns to dislodge the material and restart milling.

10.6 Blockage Removal

Never begin to unblock a machine until the PTO has

been disengaged, the engine stopped with the key

removed from the ignition, and the machine has

come to rest. Whilst power is connected to the machine

the red beacon will remain flashing until the rotor comes

to rest.

Should the mill rotor and housing become blocked, first

remove any material on the conveyor below the screen.

A short reverse rotation of the bale chamber is

recommended before attempting to restart the mill rotor.

Further access may be gained by removing the screen to

gain access to the rotor or by entering the bale chamber

to clear material from around the mill rotor.

10.7 Folding for Transport

Before folding the conveyor for transport ensure the

bale chamber is positioned so that the rubber stops

on the conveyor sit on the support pads on the bale

chamber. Arrows on the front of the bale chamber and

chain drive guard indicate this position.

11.0 MACHINE PROTECTION DEVICES

IMPORTANT:

The machine is fitted with a shear bolt on

the PTO shaft connecting the tractor to the machine. If

the PTO shaft is engaged harshly or after a blockage, the

shear bolt may fail and require replacement. See

paragraph 12.7 in the maintenance section.

Shearbolt

Grade 10.9

Bolt M12 x 55mm

12.0 MAINTENANCE

12.1 Safety

Never open the guards surrounding the driveline or

enter the bale chamber unless the PTO has been

disengaged, the engine has been stopped, the key

removed and the machine come to rest. Whilst power is

connected to the machine the red beacon will remain

flashing until the rotor comes to rest.

The mill rotor will take approximately 2 minutes to

come to rest from operating speed.

12.2 Lubrication and regular maintenance.

A regular visual inspection of the mill for parts showing

any excessive wear is recommended. Parts requiring

particular attention are the hammers/blades for wear and

elongation of the pivot hole. Also check the pivot rod

retaining pins are in place and there is no excessive wear

on the rods. The holes for the hammer pivot rods in the

discs of the mill rotor should be inspected for elongation

and wear.

Good quality semi-solid grease should be applied to the

grease points as shown on the relevant lubrication chart

on page 2.

The frequencies stated are hours of use.

Other maintenance points are shown in table 3 below

Table 3 Quick reference maintenance table

12.3 Wheel Changing

Serious accidents, including fatalities, have been

caused by unsafe practices during wheel/tyre

changing and when inflating tyres.

When using jacks to lift or support the machine:

a)

Use a jack capable of lifting 3 Tonnes for lifting the

machine. The jack should have a minimum height

of 470 mm and be able to extend to a length of

520 mm;

b)

Use the jacking point identified in the figure 3;

c)

Position axle stands to give additional support;

d)

Apply the handbrake to prevent movement.

10

Greasing

See separate chart on page 2

Hydraulic oil

Check oil level daily

Oil Cooler

Check / clean cooler screen

fins daily

Return line filter

Check gauge weekly

Bale chamber

chain tension

After first day then

weekly depending on use

Mill rotor belt

tension

Weekly

Hydraulic pump

drive belt tension

Monthly, depending on use

Tyre pressures &

wheel nuts

Weekly

Hydraulic oil

Analysis of oil condition

annually

3

120 - 150 (160-200)

2

104 - 120 (140 -160)

1

90 - 104 (120 -140)

Mode

Tractor power kW (hp)