Installation Guide

eX-Series

Networked Door Controllers

To Register your Product, Visit

http://www.tdsi-product-registration.co.uk

UM0022_GB Issue 1 10/07

NOTICES

Manufacturers Details

Time and Data Systems International Ltd (TDSi)

Unit 10 Concept Park

Innovation Close

Poole

Dorset

BH12 4QT, UK

T:

+44 (0)1202 723535

F:

+44 (0)1202 724975

E:

W:

http://www.tdsi.co.uk

Sales:

+44 (0)1202 724999

Support

(UK Only):

0871 2262318

Copyright Notice

Copyright © 2007 Time and Data Systems International Ltd

(TDSi). This document or any software supplied with it may

not be used for any purpose other than that for which it is

supplied nor shall any part of it be reproduced without the

prior written consent of TDSi.

TDSi Policy

Time and Data Systems International Ltd operate a policy of

continuous improvement and reserves the right to change

specifications, colours or prices of any of its products without

prior notice.

Compliance

This product complies with the following European Directives:

Low

Voltage

73/23/EC

89/68/EC

EMC

89/336/EC

WEEE

2002/96/EC

1 OVERVIEW

Thank you for purchasing this eX-series product from TDSi. This product features a fully featured,

high quality power supply unit providing a regulated 13.8 VDC output supplying continuous full rated

current to the access control unit and locks and an additional 0.5 A for trickle charging a standby

battery. The load output features full electronic short circuit protection under mains operation.

LEDs are provided to indicate mains present and fault conditions.

For fully-detailed installation instruction, please refer to the Installation Manual on

the accompanying CD-ROM.

2

INSTALLING THE CONTROLLER

Note: It is essential to observe anti-static precautions when working inside the cabinet.

Note: This product is NOT SUITABLE for external installation and must be installed

according to all relevant safety regulations applicable to the application.

2.1 MAINS

INSTALLATION

This product must be fed from a mains power source having a separate (approved) disconnect

device and fitted with a fuse or other over-current protection device rated at 3 A maximum. Ensure

that the disconnect device used has appropriate earth fault protection to the applicable standard.

Fix the PSU to the wall or other support structure in the correct orientation i.e. with the

transformer and space for the standby battery at the bottom of the unit using the screws

supplied. Allow clearance to for the lid of the product to be fitted and removed.

Note: The

product is to be installed in an area with free air movement and with a minimum of

100 mm clearance between the sides and lid of the power supply case and any adjacent

surface (wall, ceiling or other partition).

This

equipment

MUST

be earthed.

Knock-outs (12) are provided in the case for mating with external trunking or conduit.

The mains input cable must be to the applicable standard with a 3 A or greater current

capacity, i.e. 0.5 mm

2

nominal conductor area, having a minimum operating voltage of

300/500 Vac.

The mains cable should be routed to use different entry/exit holes (4) in the case to those used

for other connected equipment (e.g. readers, locks, network cables, inputs, outputs etc.)

Grommets should be used to protect cable sheaths from chaffing. These should meet a

minimum flammability specification of UL94 HB and should be correctly sized i.e. close fitting

with respect to the cable sizing.

The mains input cable should be securely fastened to the case saddle (1) in position using a

cable tie.

2.2

INSTALLATION OF OTHER SERIVES

Refer to the tables in this guide for connection of other items e.g. readers, locks,

communications, inputs, outputs, etc.

Solder and tape all connections. DO NOT use crimps, B-connectors, wire nuts or punch-

down blocks.

All cable runs must be at least 2 m in length to allow any induced static to dissipate before it

readers the controller electronics.

The screen braid of the cables must be terminated to the earthing clamps (11) on the side

of the chassis plate unless the peripheral is connected to ground. Any portion of the

unscreened cable should be kept as short as possible and not be allowed to protrude into

the area of the electronics.

Screen braids of cables are to be connected at one end only, usually at the controller end.

Exceptions to this are if the equipment (reader, lock etc.) are metal cased and mounted on

a metal surface (such as a door frame) and in this case the screen should be connected at

the equipment end.

When

using

RS-485

It is the responsibility of the installer to follow all local and national electrical codes that may

apply.

Never install any access control system until approval has been obtained from the local fire

authority. IN particular note that the use of an exit (egress) button may not be legal.

Single-actions exit may be required.

2.3

CONTROLLERS WITH IN-BUILT ETHERNET PORTS

Some models are supplied with a Ethernet (TCP/IP) port. When installing these models, please

note the following points.

If you are connecting the eXcel

4

to an existing network, contact the network administrator to

be allocated a suitable IP address.

Before connecting the Ethernet port, reposition the 5 DIP-switches accordingly. Switch 1

should be ON (in the up position). Switches 2, 3, 4 and 5 provide RS-485 end of line

termination. Termination is required when connecting multiple controllers using RS-485

from the IP connected controller.

Note: Only one controller needs to have it’s

termination switches set for the entire RS-485 communication line.

Install the ferrite core (supplied) to the Ethernet patch lead, fitted as closely as possible to

the plug as possible (see picture below).

Connect the eXcel

4

to the network or computer, using a lead with a ferrite sleeve installed.

If there is more than one eXcel

4

, they can be connected at this stage.

Note the UID number of each controller and each unit to assist in the identification during

commissioning.

During commissioning, you may find it useful to observe the diagnostic lights on the

Ethernet port. A steady light shows that a connection exists. A flashing light shows that

there is data on that communications line (although this does not necessarily mean that this

data is directed at the controller).

For communications using a separate serial to Ethernet converter or serial to RS-485

converter, please refer to the documentation supplied with those devices.

3 COMISSIONING

Caution: Risk of explosion if the battery fitted is of an incorrect type.

Note: Dispose of used batteries in accordance with the battery manufacturer’s

instructions and to comply with all local and national regulations.

Disconnect the plug connector that supplies power to the controller circuit board.

Make the mains connection to the fused mains terminal block observing the wiring

information on the (yellow) label next to the terminal block. Ensure that the mains isolator

(disconnect device) is open.

Apply mains voltage to the input. Ensure that the green

MAINS ON

LED is illuminated.

Disconnect the mains by opening the mains isolator.

Reconnect the plug connector that supplies power to the controller circuit board.

Reconnect the mains by closing the mains isolator. Ensure that the green

MAINS ON

LED

is illuminated.

Connect the standby battery (not supplied), red cable to the +ve (red) terminal and black

cable to the –ve (black) terminal and fit the battery into the space provided.

If the battery has little or no charge, allow it to charge for a short period of time. Refer to

section

8 for battery recharge times.

Disconnect the mains by opening the mains isolator. Ensure that the green

MAINS ON

LED is extinguished and the amber

BATTERY STANDBY ON

LED is illuminated.

Reconnect the mains by closing the mains isolator. Ensure that the green

MAINS ON

LED

is illuminated and the amber

BATTERY STANDBY ON

LED is extinguished.

With the unit still powered up, remove the PCB output fuse () and ensure that the red

FAULT

LED is illuminated. Also the red LED on the distribution PCB will be extinguished.

Refit the output fuse and check that the red

FAULT

LED is extinguished and the red LED

on the output distribution board (2) is illuminated.

Ensure that the Memory Battery Link

(9) jumper is fitted.

Note all UID Numbers (10) of the controllers to assist with set-up of the controllers

Perform a final check on the security of all wiring

Close the case ensuring that all 4 lugs are located correctly in their respective cut-outs in

the case saddle.

Secure the cover in place using the screws provided.

4 OPERATING

INSTRUCTIONS

Once all connections have been correctly made, there are no further operations required. All

configuration of the door controller is achieved through either the use of eXguard eXpress or

eXguard PRO PC software. In addition, eXpert

2

master controllers allow the connection of a

local programming device to the 25-way port on the front of the controller.

The

green

MAINS ON

LED will be illuminated whilst the mains supply is present. Should

mains fail and a backup battery with sufficient charge be fitted, the amber

BATTERY

STANDBY ON

LED will illuminate. In the event of a failure, the red

FAULT

LED will be

illuminated.

5 MAINTENANCE

Note: Reference should be made to the battery manufacturer’s documentation to determine

typical/expected battery life with a view to periodic replacement of the battery.

There is no regular maintenance required other than periodic testing and replacement of the

standby battery.

If the output of the PSU fails (indicated by the red

FAULT

LED being illuminated) the cause of

the failure should be investigated e.g. short circuit load etc. The fault should be rectified

before restoring the power to the PSU. The fuses may need to be replaced. Ensure that the

replacement fuse is of the correct type and rating.

6

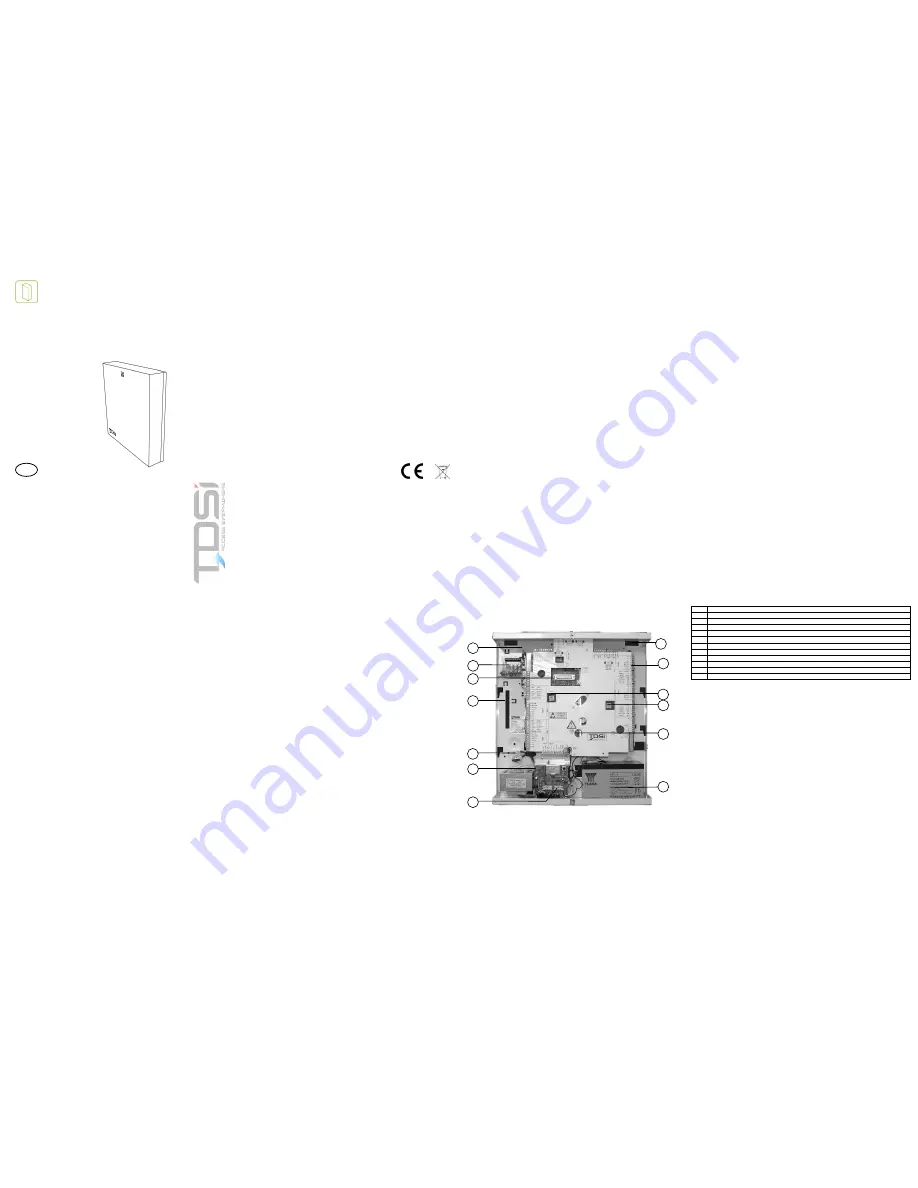

LAYOUT OF EX-SEIRES ACCESS CONTROL UNITS

The following diagram shows the layout of the controller. Please familiarise yourself with the layout

of the product before attempting installation.

Figure 1 - Layout of eX-Series (eXpert

4

Shown)

*certain models only

1 Saddle

2

Output Distribution Board and Fuses

3 Local

programming

port*

4 Cable

Entry/exit

holes

5

Fused Mains Terminal Block

6

Status Indication LEDs (green, amber and red)

7 Output

Fuse

8

Standby Battery (not supplied)

9 Memory

Battery

Link

10 Controller

UID

Numbers

11

Cable Screen Braid Earthing Clamps

12 Trunking

Knock-Out

GB

1

2

3

5

4

6

7

8

9

10

10

11

12