CM4 App Note 260424 issue 2.1.docx

Document No. 260424

Page 28 of 29

16. Output Modules

Refer to datasheet for output module ratings

Adjusting output voltages

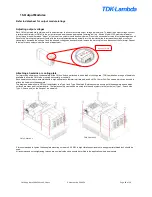

Each CM output module contains a built-in potentiometer to allow for accurate output voltage adjustments. To adjust the output voltage, connect

a calibrated voltmeter (or DMM) to the output terminals and insert an appropriate trimming tool (e.g. Bourns Model H-90, maximum diameter

3mm) through the hole

marked “Adjust” at the top of the output module as shown below. Do not use excessive force as this may damage the unit.

Ensure the trimming tool mates correctly with the internal potentiometer and slowly turn the tool clockwise to increase the voltage or counter-

clockwise to decrease the voltage. Once the desired voltage has been achieved, remove the trimming tool and disconnect the voltmeter. Repeat

this step for each output module in need of adjustment.

Attaching a heatsink or cooling plate

For improved performance, the baseplate of the CM4 unit can be attached to a heatsink or cooling plate. TDK-Lambda has a range of heatsinks

available to allow the CM4 to be mounted horizontally or vertically.

Each heatsink comes pre-assembled with a high performance thermal interface pad and 6 x M4 x 10mm Pozi Pan screws which can be used to

attach the heatsink to the baseplate.

The diagrams below show a CM4 unit attachment to a Type 1 and Type 2 heatsink. Before assembly ensure both the baseplate and heatsink

surfaces are clean and free from debris. The final assembly can then be mounted into the end system via the four holes (Type 1: 2 each side,

Type 2: 2 each end) on the flange of the heatsink.

It is recommended to tighten the baseplate mounting screws to 0.55 NM. In high vibration environments, an appropriate thread lock should be

used.

All recommended screw tightening torques are nominal values and should be verified in the application where appropriate.

CM4 Heatsink 1

CM4 Heatsink 2

Voltage Adjust