CM4 App Note 260424 issue 2.1.docx

Document No. 260424

Page 27 of 29

15. Reliability

The CM4 series has undergone extensive testing, including HALT and Environmental testing. Reliability data is collected on an ongoing basis.

Please contact TDK-Lambda for the most up to date reliability data.

The reliability data quoted in the datasheets are the calculated

failures per million hours

(FPMH) using the Telcordia SR-332, issue 2 standard.

The procedure defined in SR-332 allows several different techniques to be used for calculating MTBF and when evaluating competing MTBF

figures it is important that only the same techniques are compared.

The quoted CM reliability figures use Method I Case 3, Ground, Fixed, Controlled which specifies an ambient temperature of 30°C and an upper

confidence level of 90%. It is also assumed that the product is operated at 100% duty cycle, has an input voltage of 220V

RMS

, an output power of

600W and that the baseplate temperature is the same as the ambient temperature.

The table below shows a summary of the FPMH & MTBF for all system components and for a typical fully assembled system.

Assembly

Failure Rate (FPMH)

MTBF (Hrs)

Input module

0.962972

1038452

Transformer

0.371919

2688754

S1

0.415368

2407499

S2

0.397808

2513774

S3

0.398170

2511487

S4

0.405630

2465300

CM4 with 4 S1 modules

2.996363

333737.934

To calculate the MTBF of any CM system,

Add the FPMH figures for each system component to give the total FPMH.

Get the MTBF by dividing 1,000,000 by the total FPMH.

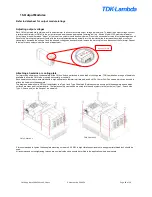

The variation in FPMH is shown in the graph and table below.

Temp

Input module

Transformer

S1

S2

S3

S4

CM4 with 4 S1 modules

0

0.41329578

0.127619

0.192619

0.185396

0.186105

0.186243

1.291276945

10

0.54688976

0.178886

0.245347

0.235357

0.235992

0.2362

1.678671789

20

0.72397837

0.255159

0.316147

0.302737

0.30326

0.305183

2.206465072

30

0.96297168

0.371919

0.415369

0.397808

0.39817

0.40563

2.951868534

40

1.29407059

0.555049

0.560829

0.538309

0.538452

0.559393

4.046103211

50

1.76616217

0.846405

0.782692

0.754326

0.754185

0.803972

5.707742381

60

2.46010898

1.315415

1.130884

1.095712

1.095216

1.202005

8.299340054

70

3.50420104

2.067304

1.686039

1.643019

1.642101

1.855247

12.39791075

80

5.09894211

3.266645

2.575169

2.523173

2.52177

2.925702

18.91140128

90

7.55815578

5.160517

3.995269

3.93316

3.931214

4.659641

29.23795696

100

11.3495991

8.112606

6.236851

6.163284

6.160733

7.430093

45.4531658