User manual

3-6

DSC/DSCT Series

3.7. GETTING

STARTED

1.

Verify that the connections are well done, that the terminals are well tighten and that the correct resolver

cable is used (see par 5.1).

2.

Disconnect the power terminals of the motor.

3.

Supply the drive and after a laps of time it will appear at the display the stable term “ stop” if there are no

alarms, light blinks if there are.

4.

Configure the drive parameters: inputs (

c1

-

c5

), outputs(

c7

-

c8

), and the motor parameters, motor

current (

P56

), motor poles (

P53

), resolver poles (

P54

), ecc.

5.

Set at a low value (5%) the internal limits,

P35

,

P36

, and set to zero the velocity reference.

6.

Reconnect the power terminals of the motor and start running (L.I.2).

7.

If no alarm appears, on the display will appear the motors speed in RPM.

8.

The motor must be in stillstand the reference is digital or moving very slowly if analog.

9.

Setup the limits

P35 P36

and calibrate if necessary the speed offset with the

P4

parameter.

10.

Give some reference and verify the correct working, in particular for a correct speed and eventually tune

the controller parameters (

P23, P24

) for a better dynamical response of the drive.

11.

Execute motor cycles and see that everything is correct.

12.

Save the parameters in EEPROM.

ADVISING

: If during the operativity just explained, in particular at points 8 and 10, the motor goes over

cycles or it doesn’t move or it moves in kicking way, verify the correct execution of the electric cables.

The drive is already tuned to the motor specified at the ordering.

3.8.

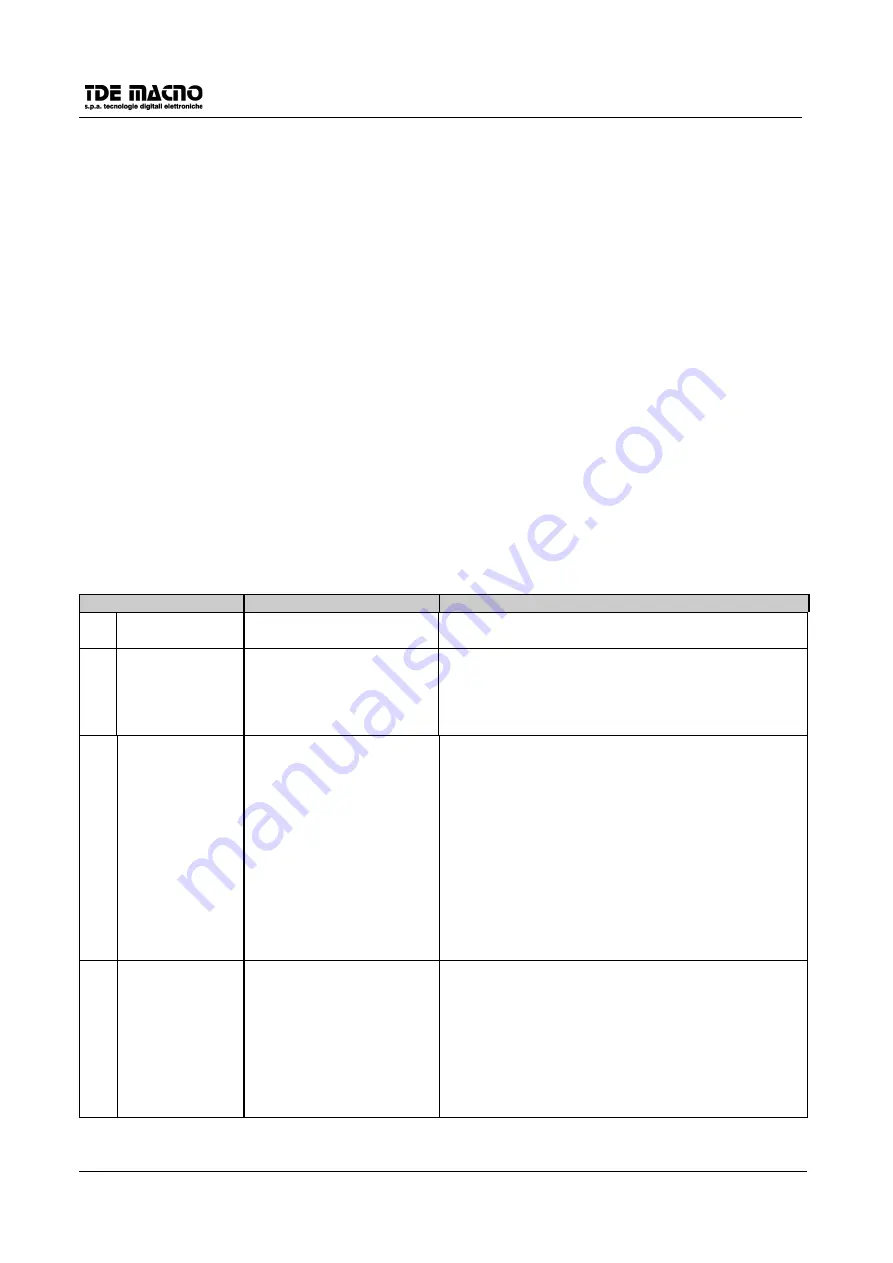

MALFUNCTIONING WITH ALARM SIGNAL : DIAGNOSIS

SAFETY ACTIVE

DESCRIPTION

REMEDIES

A1

Internal supply

error

The internal voltages are

incorrect

Check the +24V in the pin J1-9 and J1-10

A2

RAM , EEPROM

alarm

The drive reads wrong

parameter values

If the problem remains after turning on/off the drive, it

is necessary to make the C41 configuration

(reloading default values) or C42 (reloading EEPROM

values) and than use C43 (EEPROM writing). See

par. 3.5

A3

Power alarm

The output current from the

drive has reached such

levels that the saturation

control circuit of the

I.G.B.T. has intervened;

this may be caused by an

overcurrent due to

dispersion in the cables or

in the motor or to a short

circuit between the drive

output phases. Or it may be

due to a breakdown in the

regulation.

Check the connection cables particularly on the motor

side of the terminal block to remove any dispersion or

short-circuiting; check the insulation of the motor

itself, doing a dielectric rigidity test, and if necessary

replace it.

Check that the drive power circuit is working by

making it run after disconnecting the motor; if the

safety device intervenes the power circuit is

damaged.

If the safety device only intervenes during working it

could be a matter of regulation (replace it along with

the current transducers) or vibrations causing voltage

transients.

A4

Radiator thermal

switch alarm

The radiator temperature

sensor has switched on

because the radiator

temperature is too high.

Check the drive cooling circuit ; the ventilator, its feed

and the slits and filters for the entry of air into the

cabinet ; if necessary replace them or clean them

and ensure that the ambient temperature (near to the

drive) is within the permitted limits for the technical

characteristics.

If everything is in order and the alarm continues even

when the drive is cold check the connecting wires to

the thermal switch.