5-2

USER INTERFACE

Model C706

User Interface

5

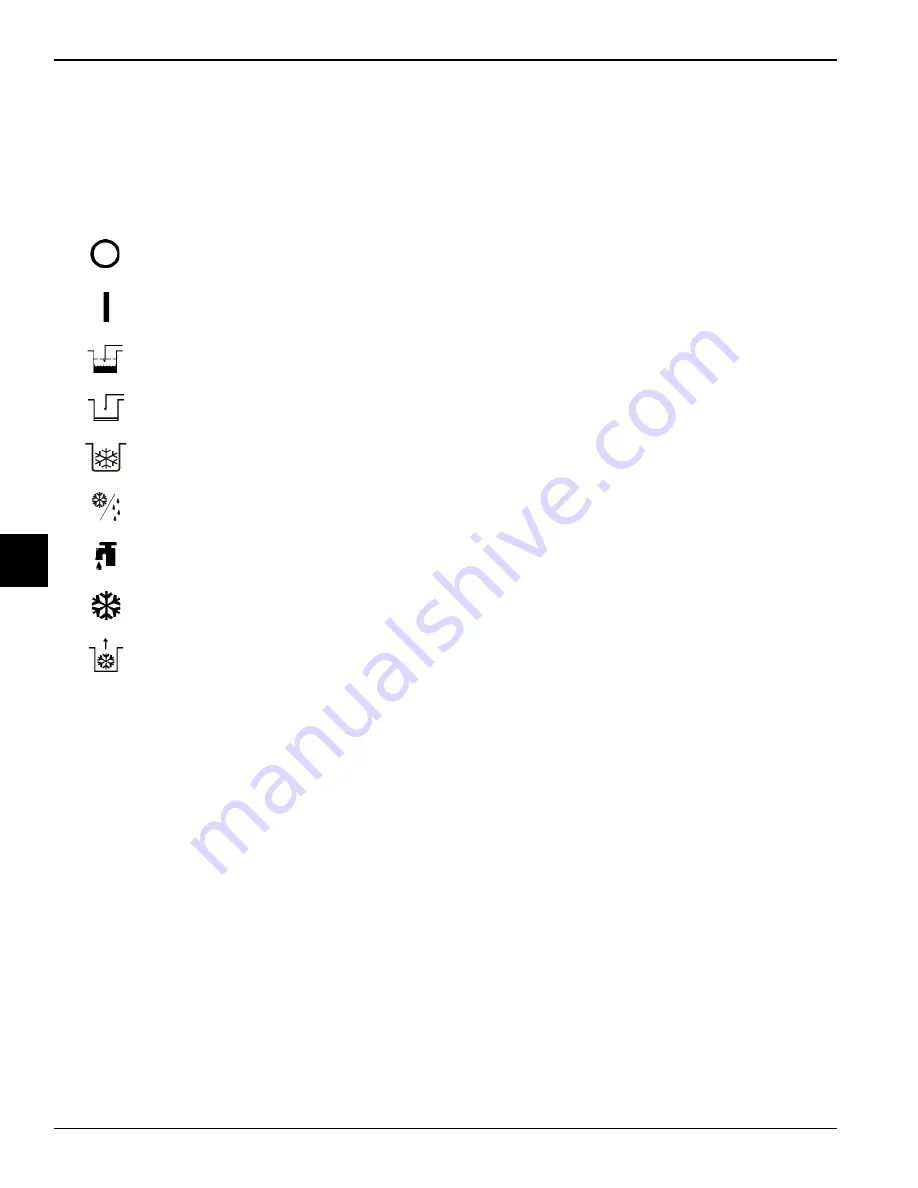

Symbol Definitions

To better communicate in the international arena,

symbols have replaced words on many of our operator

switches, function, and fault indicators. Your Taylor

machine is designed with these International symbols.

The following chart identifies the symbol definitions:

= OFF

=

ON

= MIX LOW

= MIX OUT

= MIX REF

= STANDBY

= WASH

= AUTO

= PUMP

Power Switch

When placed in the ON position, the power switch allows

Softech™ control panel operation.

Indicator Lights

When the MIX LOW indicator light flashes, the mix tank

has a low supply of mix and should be refilled as soon as

possible. When the MIX OUT indicator light begins to

flash, the mix tank has been almost completely

exhausted and has an insufficient supply of mix to

operate the freezer. At this time, the Standby and Auto

modes are locked out and the freezer shuts down. To

initiate the refrigeration system, add mix to the tank and

press the AUTO key. The freezer will automatically begin

operation.

MIX REF Key

When the MIX REF key is pressed, the indicator light

comes on and the mix hopper refrigeration system is

operating. The MIX REF function cannot be canceled

unless the Auto or Standby modes are canceled first.

STANDBY Key

The separate hopper refrigeration (SHR) system and the

cylinder temperature retention (CTR) system are

standard features. The SHR system uses a separate

small refrigeration system to maintain the mix in the

hopper below 40°F (4.4°C) to ensure bacteria control.

The CTR system works with the SHR system to maintain

a good quality product. During long no sale periods, it is

necessary to warm the product in the freezing cylinder to

approximately 35°F to 40°F (1.7°C to 4.4°C) to prevent

overbeating and product breakdown.

To activate the SHR system and CTR system, press the

STANDBY key. Remove the air orifice and place the feed

tube (end without the hole) into the mix inlet hole.

When the STANDBY key is pressed, the indicator light

comes on, indicating the CTR system has been

activated. In the Standby mode, the Wash and Auto

functions are automatically canceled. The Mix Ref

function is automatically locked in to maintain the mix in

the hopper.

To resume normal operation, press the AUTO key. When

the machine cycles off, the product in the freezing

cylinder is at serving viscosity. At this time, place the feed

tube

(end with the hole) into the mix inlet hole and install

the air orifice.

WASH Key

When the WASH key is pressed, the indicator light

comes on showing that the beater motor is operating.

The Standby or Auto modes must be canceled first to

activate the Wash mode.

Summary of Contents for C706

Page 8: ...1 4 TO THE INSTALLER Model C706 To the Installer 1 Notes ...

Page 14: ...3 4 SAFETY Model C706 Safety 3 Notes ...

Page 36: ...6 14 OPERATING PROCEDURES Model C706 Operating Procedures 6 Notes ...

Page 42: ...8 4 TROUBLESHOOTING GUIDE Model C706 Troubleshooting Guide 8 Notes ...

Page 44: ...9 2 PARTS REPLACEMENT SCHEDULE Model C706 Parts Replacement Schedule 9 Notes ...

Page 48: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C706 Limited Warranty on Equipment 10 Notes ...

Page 52: ...11 4 LIMITED WARRANTY ON PARTS Model C706 Limited Warranty on Parts 11 Notes ...