6-4

OPERATING PROCEDURES

Model C706

Operating Procedures

6

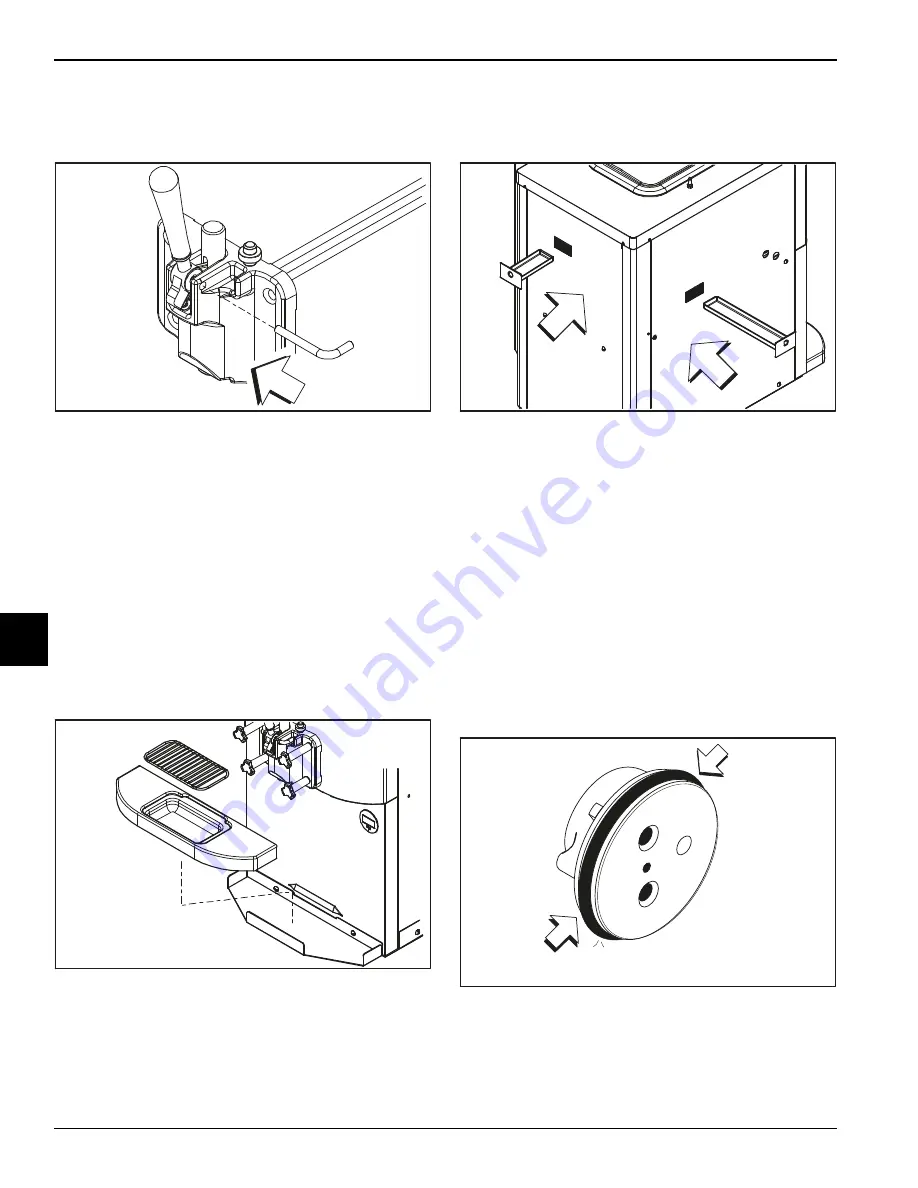

15. Install the adjustable draw handle. Slide the fork over

the bar in the slot of the draw valve. Secure it with the

pivot pin.

Figure 6-11

Note:

This machine features an adjustable draw

handle to provide the best portion control. The draw

handle can be adjusted for different flow rates. See

page 5-3 for more information on adjusting this

handle.

16. Insert the baffle rod through the opening in the beater

and seat the door flush with the freezing cylinder.

With the door seated on the freezer studs, install the

handscrews. Tighten them equally in a crisscross

pattern to ensure the door is snug.

17. Install the front drip tray and the splash shield under

the door spout.

Figure 6-12

18. Slide the rear drip pan into the hole in the side panel.

Slide the pump drip pan into the hole in the back

panel.

Figure 6-13

Mix Hopper Assembly

1. Inspect the rubber and plastic pump parts. The

O-rings, check rings, and gaskets must be in 100%

good condition for the pump and machine to operate

properly. They cannot work properly if nicks, cuts, or

holes are present. Inspect the plastic pump parts for

cracks, wear, and delamination of plastic. Replace

any worn or damaged parts immediately and discard

the old parts.

2. Assemble the mix inlet assembly. Slide the O-ring

into the groove of the valve body cap.

Do not

lubricate the O-ring.

Figure 6-14

10503

10504

10357

15109

Summary of Contents for C706

Page 8: ...1 4 TO THE INSTALLER Model C706 To the Installer 1 Notes ...

Page 14: ...3 4 SAFETY Model C706 Safety 3 Notes ...

Page 36: ...6 14 OPERATING PROCEDURES Model C706 Operating Procedures 6 Notes ...

Page 42: ...8 4 TROUBLESHOOTING GUIDE Model C706 Troubleshooting Guide 8 Notes ...

Page 44: ...9 2 PARTS REPLACEMENT SCHEDULE Model C706 Parts Replacement Schedule 9 Notes ...

Page 48: ...10 4 LIMITED WARRANTY ON EQUIPMENT Model C706 Limited Warranty on Equipment 10 Notes ...

Page 52: ...11 4 LIMITED WARRANTY ON PARTS Model C706 Limited Warranty on Parts 11 Notes ...