8

TARGET ECO I FEEDING, rev.09

TARGET ECO I FEEDING

2.3.2

Feed Distribution Process

The feed delivery process starts at the

beginning of a feed cycle. At that moment,

the controller sends the first feed ration

to the proper drop(s). It then waits for the

drops to empty out (rest time) before clean-

ing out the feed line. When the cleaning

process is over, the controller starts deliv-

ering the following ration (if applicable).

1)

Step 1 – Feed Delivery

•

Opening of the Drops:

With an actuator:

At the start-up of a feed cycle, the con-

troller opens the actuator to the position

associated with the first ration.

Without an actuator

:

At the start-up of a feed cycle, the con-

troller opens all drops that are asking for

the first feed ration.

•

Feed Distribution:

With a proximity sensor to stop the feeder:

The feeder runs while drops are opened. It

keeps on running up until the drops are full.

(The controller knows the drops are full

when the proximity sensor associated with

the ration detects feed. If only one prox-

imity sensor is used, the controller consid-

ers drops to be full when this sensor de-

tects feed).

Note that if a proximity sensor is used, an

alarm is generated if the sensor does not

detect feed after the

“Max Run Time”

. This

type of alarm generally occurs when a bin

is empty.

Without a proximity sensor:

Once the drops are opened, the feeder runs

during the

“Max Run Time”

associated with

the ration and then stops.

FEED CYCLE

STEP 1

STEP 2

STEP 3

STEP 1

STEP 2

STEP 3

Feed

Rest

Clean

Feed

Rest

Clean

Ration #X

Ration #X +1

2)

Step 2 – Resting Time

When drops are full, the controller stops

the feeder during the

“Rest Delay”.

This

delay represents the period of time re-

quired to empty out the drops.

3)

Step 3 – Cleanout

Cleanout periods allow evacuating feed left-

overs from the feed line. To empty the feed

line, the controller restarts the feeder while

the drops are opened. An optional cleanout

auger can also be used to send feed left-

overs back to their original bin.

During the cleanout period, the feeder

motor and the optional cleanout auger are

activated in order to evacuate feed from

the line. This cleaning period can either end

after a user-defined delay or when a cer-

tain proximity sensor stops detecting feed

(enable the “Feed Gap Delay” in the In-

stallation Setup if you want to use a prox-

imity sensor to stop the cleaning period

(see sec. 5.3)).

The controller repeats step 1 to

3 for each ration to be delivered

during the cycle.

37

TARGET ECO I FEEDING, rev.09

TARGET ECO I FEEDING

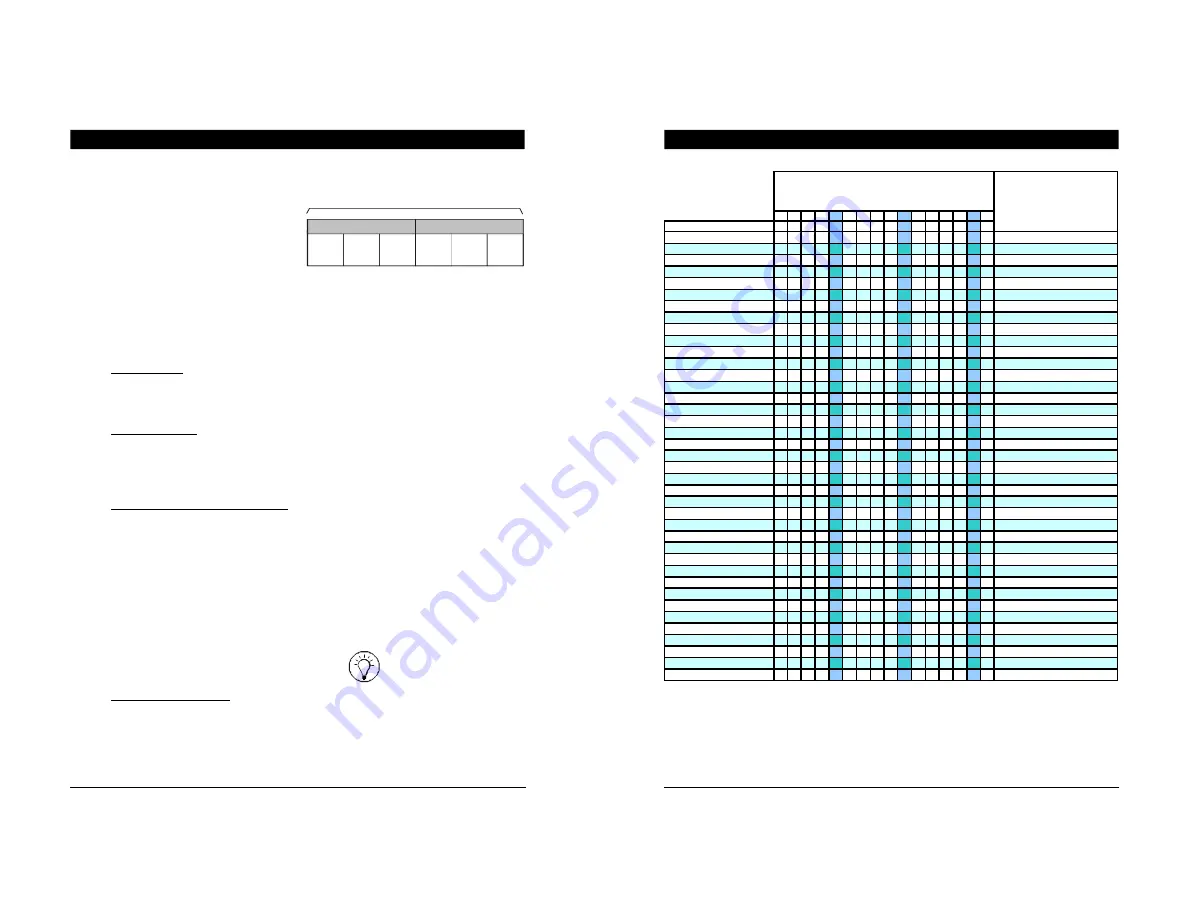

ID NUMBER

of the relay panel

(ID # 2 to ID #19)

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

OUTPUTS

1

2

3

4

5

6

7

8

9 10 11 12 13 14 15 16

Drop 19

_________ ( ID #2 to ID #19)

Drop 20

_________ ( ID #2 to ID #19)

Drop 21

_________ ( ID #2 to ID #19)

Drop 22

_________ ( ID #2 to ID #19)

Drop 23

_________ ( ID #2 to ID #19)

Drop 24

_________ ( ID #2 to ID #19)

Drop 25

_________ ( ID #2 to ID #19)

Drop 26

_________ ( ID #2 to ID #19)

Drop 27

_________ ( ID #2 to ID #19)

Drop 28

_________ ( ID #2 to ID #19)

Drop 29

_________ ( ID #2 to ID #19)

Drop 30

_________ ( ID #2 to ID #19)

Drop 31

_________ ( ID #2 to ID #19)

Drop 32

_________ ( ID #2 to ID #19)

Drop 33

_________ ( ID #2 to ID #19)

Drop 34

_________ ( ID #2 to ID #19)

Drop 35

_________ ( ID #2 to ID #19)

Drop 36

_________ ( ID #2 to ID #19)

Drop 37

_________ ( ID #2 to ID #19)

Drop 38

_________ ( ID #2 to ID #19)

Drop 39

_________ ( ID #2 to ID #19)

Drop 40

_________ ( ID #2 to ID #19)

Drop 41

_________ ( ID #2 to ID #19)

Drop 42

_________ ( ID #2 to ID #19)

Drop 43

_________ ( ID #2 to ID #19)

Drop 44

_________ ( ID #2 to ID #19)

Drop 45

_________ ( ID #2 to ID #19)

Drop 46

_________ ( ID #2 to ID #19)

Drop 47

_________ ( ID #2 to ID #19)

Drop 48

_________ ( ID #2 to ID #19)

Drop 49

_________ ( ID #2 to ID #19)

Drop 50

_________ ( ID #2 to ID #19)

Drop 51

_________ ( ID #2 to ID #19)

Drop 52

_________ ( ID #2 to ID #19)

Drop 53

_________ ( ID #2 to ID #19)

Drop 54

_________ ( ID #2 to ID #19)

Drop 55

_________ ( ID #2 to ID #19)

Drop 56

_________ ( ID #2 to ID #19)

Drop 57

_________ ( ID #2 to ID #19)

RELAY NUMBER

Relay 1-16 & Relay 17-32 = second 16-relay strip of 32

outputs relay panel