18

• Mandatory

• Obligatorio

• Prohibition

• Prohibición

• Indication

• Indicación

• Warning Triangle

• Triángwulo De

Advertencia

These signs will give advice for your safety

Before leaving our factory every machine

is thoroughly tested.

Follow our instructions strictly and your machine

will give you long service in normal operating

conditions.

1. Features

Use: Surface grinding of concrete or other types of

flooring. For repairing horizontal surfaces that

have been damaged by the weather, or by

improper finishing methods, or that require

removal of deteriorated coatings, overlays, or

buildups.

Tools:

1) 2 x 2 x 4” (50 x 50 x 100 mm) size, Six (6) per unit.

In any of the types shown below:

a) Grinding Stones [FIG. 14]

b) Tungsten Carbide Segment Block

[FIG. 16].

c) Tungsten Carbide Impregnated Grinding

Block (Not Shown)

d) Scarifier Blocks (Star, Beam, TC wheels)

[FIG. 27 & FIG. 28].

e) Wire Brushes [FIG. 26].

f) Diamond Blocks [FIG. 15].

2) Multi-Segmented Diamond Disks: Two (2) disks per

unit, 10” (250 mm) diameter, 10 or 20 diamond

segments on each disk [FIG. 24 & FIG. 25].

3) Tool Holding Pad, with “hook-and-loop” type of tool

attachment, holds the following [FIG. 19]:

a) Scrubbing Pad [JJ] [FIG. 19]: Two (2) pads

per unit, 10” (250 mm) diameter, Nylon

mesh Impregnated with Silicon Carbide.

(For information contact your Dealer)

Depth of Cut (Maximum):

See Section 4 (Tool Installation & Application)

Maximum material Size: N/A

Nominal & Operating Weight: See “Specifications”.

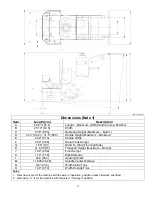

Dimensions, Grinding Width, Spindle Shaft RPM:

See “Saw Dimensions”.

Before starting up machine make sure you

read these instructions and are familiar

with the operation of this machine.

The working area must be completely clear,

well lit and all safety hazards removed (no

water or dangerous objects in the vicinity)

The operator must wear

protective clothing

appropriate to the work he

is doing.

We recommend hearing,

respiratory and eye

protection.

Any persons not involved in the work,

should leave the area.

Only work of flat horizontal areas.

Working on steep slopes or hills could

cause the operator to lose control of the

machine. This could result in injury or

death to the operator or other persons in

or near the work area!

2. Assembly

When unpacked, this unit is fully assembled,

except for installation of the grinding “tools”. For

tool installation See Section 4 of this document.

The dealer or end user must do the installation of

optional or accessory items, such as a water tank

kit.

3. Check Before Operating

All Models:

Take into account the working conditions from a

health and safety point of view.

For start up refer to the engine, or motor manual.

Summary of Contents for DT11H

Page 7: ...7...

Page 8: ...8...

Page 9: ...9...

Page 10: ...10...

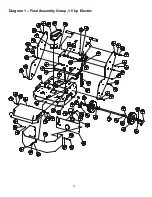

Page 28: ...28 Diagram 1 Final Assembly Group 1 5 hp Electric...

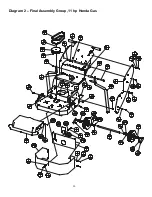

Page 30: ...30 Diagram 2 Final Assembly Group 11 hp Honda Gas...

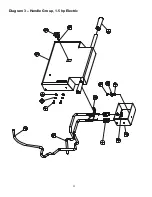

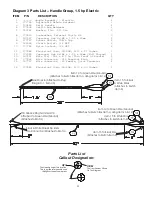

Page 32: ...32 Diagram 3 Handle Group 1 5 hp Electric...

Page 36: ...36 Diagram 5 Motor Group 1 5 hp Electric...

Page 38: ...38 Diagram 6 Engine Group 11 hp Honda...

Page 40: ...40 Diagram 7 Gearbox Assembly All Models...

Page 42: ...42 Diagram 8 Water Tank Kit Optional P N 177855 Complete Kit...

Page 50: ...50 Diagram 15 Wiring Diagram 1 5hp Electric Model...