BEARINGS

: All the bearings on your Tarco® 3000 Combination Dump Body/Spreader are sealed

and self-aligning. The bearings are designed to operate at high speed under continuous operation.

Since the bearings on your spreader operate as low as 20 RPM, more harm will be done to them by

over greasing than by under greasing. When lubrication is required, use a hand-operated grease gun

and light bearing grease. It is a good idea to keep the bearing race and any shafts protruding through

the bearing heavily coated with grease. This coating will retard corrosion on the shaft and allow for

easier shaft removal should it become necessary.

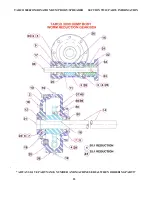

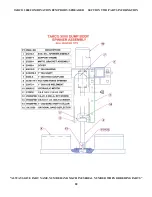

RIGHT ANGLE 20:1 & 50:1 WORM GEARBOX

: The worm gear reducer has been properly

filled with the factory and should be checked periodically during the season. At the end of each

season, fill the gearbox to the top for off-season storage. At the beginning of the next season

completely drain the gearbox and refill with fresh lube to the oil level plug. Lightly grease the

fittings. Utilize SAE 85W-90 Gear Lubricant only in the 20:1 & 50:1 reduction gearbox.

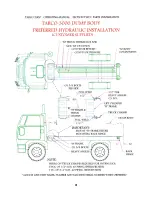

HYDRAULIC SYSTEM

: The truck mounted hydraulic pump and reservoir should be checked once

each week and refilled to 1” from the top with Chevron AWISO 46 or equal Hydraulic Oil.

DUMP BODY

: Grease fittings are provided throughout the dump body. The following items should

be greased:

Hoist cylinder upper and lower mounting blocks

Rear hinge block assembly

All tailgate latch linkage assemblies

Main center hinge for side dump operations

Flow gate jack

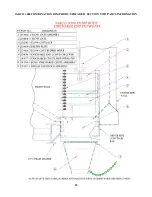

CONVEYOR SYSTEM

: Conveyor chain should be lubricated with a heavy weight oil. This will

prevent unnecessary binding and premature wear. The conveyor chain should be inspected and

adjusted periodically, apply grease to the take up grease cylinders so that the distance between the

centerline of the idler drum to the point where the chain contacts the return strips is 18” x 22”.

14

Summary of Contents for T-3000

Page 9: ...8...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

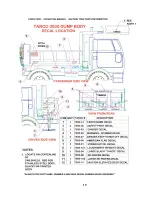

Page 23: ...TARCO 3000COMBINATION DUMP BODY SPREADER SECTION TWO PARTS INFORMATION 22...

Page 25: ...24...

Page 26: ...TARCO 3000 COMBINATION DUMP BODY SPREADER SECTION TWO PARTS INFORMATION 25...

Page 27: ...TARCO 3000COMBINATION DUMP BODY SPREADER SECTION TWO PARTS INFORMATION 26...

Page 28: ...27...

Page 31: ...30...

Page 32: ...31...

Page 33: ...TARCO 3000COMBINATION DUMP BODY SPREADER SECTION TWO PARTS INFORMATION 32...

Page 34: ...33...

Page 39: ...TARCO 3000 COMBINATION DUMP BODY SPREADER SECTION TWO PARTS INFORMATION 38...