46

Maintenance

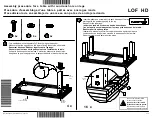

Cloth

Flathead

screwdriver etc.

Open the stop valves

(opened)

Stop valve

Loosen

Fasten

Strainer

Remove the strainer and drain the water while

holding a cloth under the filtered check valve.

5

Tools required: Flathead screwdriver

After cleaning the strainer, return it to the

original filtered check valve and fasten prop-

erly.

6

* Drain the water and clean both the water supply

pipe and hot water supply pipe.

Removing the strainer from the hot

water supply pipe may cause hot water

to spill out. Take extra care when

draining the hot water.

Caution

Water

leakage

Wipe any water that has spilled, and remove

the cloth used.

7

After checking that the strainers have been

fastened properly, open the stop valves.

8

Caution

- Fasten the strainers properly. Water

may leak if the strainers are loose.

- If waste water spills on to the floor,

wipe it dry immediately.

[Checking for water leaks]

Open the maintenance cover once per week (as a guide) and check that water is not leaking onto the

floor. If there is water leakage, the pipes within the basin body may be damaged.

Return the maintenance cover to its original

position, and attach the Urea screw (1) to

the main body.

9