3

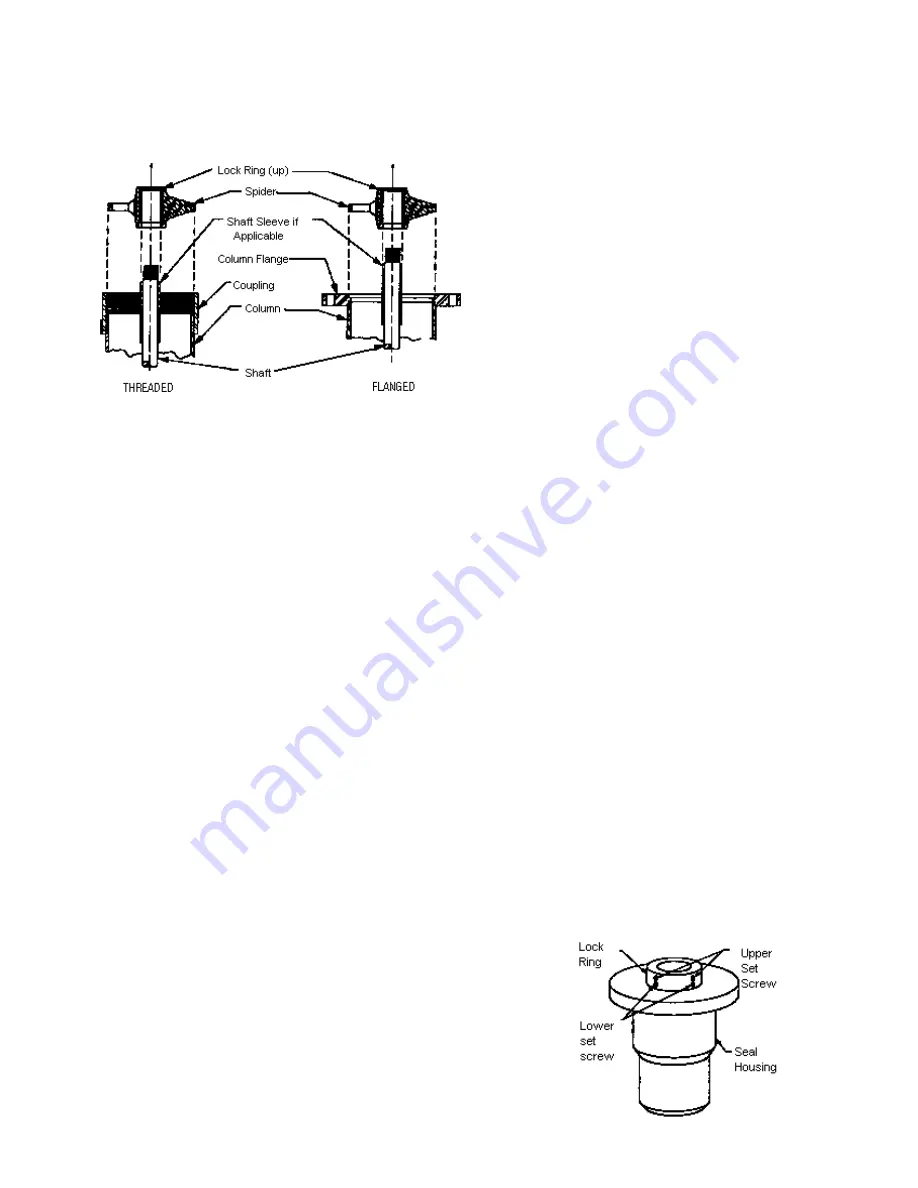

9.a If there is more than one section of threaded column, a center-

ing spider may be used. Slip the spider over the lineshaft with

lock ring on top. Screw the centering spider into the column

coupling until it butts against the column pipe. See Figure

A5.3.9 (THREADED).

Note: Some spiders may not have lock rings.

9.b If column is flanged, clean flange and the O.D. of the spider.

Slip the spider over the lineshaft with lock ring on top and

seat into spider recess. See Figure A5.3.9 (FLANGED).

10. Clean all lineshaft threads and faces thoroughly. Screw the

coupling on half of its length. Cover the coupling with a rag to

prevent foreign matter from dropping into the entrance.

11. If there is more than one section of column, repeat Section

A5.3, steps 1 through 10, for each additional section until all

of the column is assembled. Clean the thread/flange face of

the column pipe and the lineshaft projection thoroughly. Do

not attach the shaft coupling to the top piece of shaft.

A5.4: PUMP HEAD

1. Wipe a thin layer of joint compound on the top column

threads, or, if connection is flanged, on the top flange face.

Remove the packing gland assembly from the discharge

head or motor stand. Clean all machined faces of the dis-

charge head/motor stand thoroughly. Attach a sling to the

discharge head/motor stand, hoist and center over the col-

umn. Lower the discharge head/motor stand being careful

not to damage the top section of shafting, known as the

head shaft, or the stretch tube (if applicable).

2.a Set the discharge head on the top section of threaded col-

umn pipe. Screw the discharge head onto the column pipe.

2.b Align the holes of the discharge head/motor stand with the

holes of the column pipe flange, then lower until head is

resting squarely on flange. Install bolts and tighten.

3. If there is an underground outlet, place the head as close as

possible to the final position in relation to the outlet.

4.a If an adjustable top flange or threaded head is used, the

head can be readily turned to place it in alignment to the

underground outlet. In addition, the head should be turned

as needed to attain the proper shaft projection and the

correct distance from the outlet center line to the bottom of

the head. Back the packing ring off to allow ample working

room, fill the chamfer on the lower end of the flange with

lampwick packing that has been precoated with joint com-

pound. Use a generous amount of the packing and wind

the packing around in such a manner that it is screwed into

place. Screw the packing ring against the flange or bottom

of the head and tighten.

4.b If the adjustable flange is being used in conjunction with oil

tubing, the top of the tubing should be approximately 1

1

/

4

inches below the tension box mounting face of the head

after the flange is adjusted.

5. Hoist head slightly. Remove the clamp from the top piece

of column. Remove setting beams and clean surface of the

foundation itself. If there is an auxiliary line to the bowl bearing

or thermo-well, that portion immediately below and attaching

to the head should now be installed. Properly place discharge

outlet and align mounting holes with anchor bolts and lower

until head is resting squarely on the foundation.

6.a If head is resting on foundation plate, align mounting holes

of the head with tapped holes in the foundation plate. Install

and tighten cap screws.

6.b Mix a sufficient quantity of rather dry non-shrink grout. Force

as much grout under the foundation plate as possible. If

grout holes are provided, grout can be pressure-fed through

the grout holes until all cavities are filled.

6.c As the head is resting on the foundation, drive wedges

under head until proper elevation is within .005 inches of the

Total Indicated Run-out with respect to head shaft. Install

and tighten hex nuts to anchor bolts. Grout under the outer

perimeter of the head and cover the wedges with the grout.

6.d If a motor stand is used, as in an underground discharge

application, it should first be determined that the outlet in

the column aligns with the discharge piping so that no strain

will be placed on the pump. Do not make this correction

at this time, however. After checking the pipe alignment

follow Step 4a for leveling and grouting.

6.e Step 6d should be followed if there is a suction connection

to the header. It is recommended that a flexible joint of some

description be used between the suction flange and header

to compensate for any slight misalignment. If no flexible joint

is used, the header flange must be perfectly aligned so that

no misalignment is transferred to the pump.

A5.5: PACKING GLAND OR MECHANICAL SEAL

1. Packing Gland Open Line Shaft

1.a Remove the packing gland, packing rings and lantern ring

from the gland assembly. Clean the packing box thoroughly

and apply a neoprene o-ring to the receiving hole in the dis-

charge head.

1.b Slide the packing box over the head shaft. Properly adjust

mounting holes so that the grease ports of the packing gland

are directed toward the access windows of the discharge

head or motor stand. Seat the packing gland against the

discharge head/motor stand then install and tighten cap

screws. It should not be necessary to exert any side pres-

sure on the shaft in order to seat the packing box properly.

1.c Reseat packing. See Section G4 for details.

1.d Slip rubber slinger over head shaft and position just above

the packing gland.

2. Mechanical Seal Open Line Shaft

Figure A5.3.9

Figure A5.5