WISE

Damper

8

Swegon reserves the right to alter specifications. 20180620

Declaration of Conformity

Swegon AB hereby affirms that

WISE Damper with integrated radio, complies with the

essential characteristic demands and relevant regulations

specified in the following directives: 2006/42/EC (MD),

2014/53/EU (RED) and 2011/65/EU (RoHS2):

The following standards have been observed:

EN ISO 12100:2010

Safety of machinery - General principles for

design - Risk assessment and risk mitigation

EN 60204-1:2006

Safety of machinery - Electrical equipment of

machines - Part 1: Generic standards

EN 60730-1:2011

Automatic electrical controls for household

and similar use - Part 1 Generic standards

EN 60730-2-14:2009

Automatic electrical controls for household

and similar use - Part 2 Particular require-

ments for electric actuators

IEC 60529:1992+A2:2013

Degrees of protection provided by enclosures

(IP code)

EN 61000-6-2:2007

Electromagnetic compatibility (EMC). Generic

standards. Immunity for industrial environ-

ments

EN 61000-6-3:2007

Electromagnetic compatibility (EMC). Generic

standards. Emission standard for residential,

commercial and light-industrial environments

EN 300328 V1.9.2, V1.9.1,

V1.8.1

Electromagnetic compatibility and Radio spec-

trum Matters (ERM) - Wideband Transmis-

sion systems - Data transmission equipment

operating in the 2.4 GHz ISM band and using

spread spectrum modulation techniques

Person responsible for this declaration:

Name: Ingvar Hagström, Factory Manager Tomelilla

Address: Industrigatan 5, 273 21 Tomelilla, Sweden

Date: 170131

This declaration is applicable only if the product has been

installed according to the instructions in this document and

if no modifications or changes have been made on this

product.

References

www.swegon.com

Building Materials Declaration

WISE Damper product data sheet

WISE System Guide

SuperWISE II / SuperWISE II SC

User Manual

WISE Project Planning Guide VS & Cooling, Electric &

Control and Ventilation

Technical data

Output (ERP):

50 mW

Frequency band:

2.45 GHz, IMS band

(2400--2483 MHz)

Temperature sensor:

0 - 50°C ± -0.5°C

Pressure sensor:

0 - 300 Pa

With SMA

VOC sensor

450 - 2000 ppm

RH sensor:

0 - 100 RH%

IP class:

IP20

Corrosivity class:

C3

Pressure class:

A

Air tightness class, casing:

C

Air tightness class circular damper,

closed:

4

Air tightness class rectangular

damper, closed:

3

Running time open/close (90°):

120 s

Spring return actuator, running

time electricity (90°):

120 s

Return time spring:

max. 20 s (90°)

Ambient temperature

Operation:

0 – 50°C

Storage:

-20 – +50°C

RH:

10 - 95%

(non-condensing)

CE marking:

2016/42/EC (MD)

2014/53/EU (RED)

2011/65/EU (RoHS)

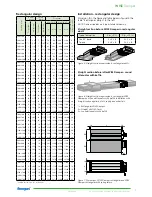

Variant

Motor

VA

Default

+1 valve

actuator

+2 valve

actuator

Normal

5 Nm

8

15

22

10 Nm

15 Nm

Spring return

5 Nm

12

19

10 Nm

20 Nm

16

23

Electrical data

Power supply:

24V AC ±15% 50 - 60Hz

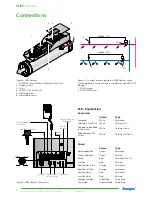

Connections pipe dim.

Power:

Screw terminal max. 2.5mm

2

Valve actuator:

Push-in spring force connections,

max. 1.5 mm

2

Max. power consumption:

See table below