WISE

Damper

2

Swegon reserves the right to alter specifications. 20180620

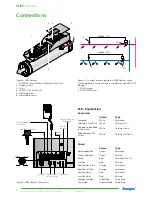

Figure 2. Installation in the duct system The ducts must be firmly

fixed to the frame of the building on each side of WISE Damper.

1. WISE Damper

2. FSR Clamp

3. Sound attenuator

1. WISE Damper

2. FSR Clamp

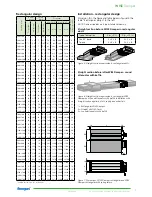

Installation, torque, dimensions and weights

Circular design

Si

ze Ø (

m

m

)

A (

m

m

)

Ins

ta

lla

ti

on

d

im

ens

io

ns

(mm

)

Normal

motor

Spring return

Flow range

To

ler

anc

e Q

*

±

5%

w

ith a

t l

ea

st ±

x l

/s

Min. (0.6

m/s)

Max. (10

m/s)

To

rq

ue

(N

m

)

W

eig

ht

(k

g)

C (

m

m

)

To

rq

ue

(N

m

)

W

eig

ht

(k

g)

l/s

m

3

/h

l/s

m

3

/h

100 574 584

5

2.5

11

5

3.0

5

18

79

285

2

125 574 584

5

2.8

24

5

3.3

7

26

123

443

2

160 574 584

5

3.2

33

5

3.7

11

40

202

728

2

200 574 584

5

3.7

19

5

4.2

18

65

315

1134

3

250 574 584

5

4.3

13

5

4.8

30

108

491

1768

5

315 600 610

10

5.2

0

10

6.2

50

180

780 2808

8

400 830 850

10

8.0

0

10

9.0

87

314 1257 4526

13

500 830 850

10

9.9

0

10

10.9 135 486 1964 7071

20

630 915 935

15

13.5

0

20

14.5 187 674 3118 11225 32

*

Installed according to the instructions

Figure 4. Dimensions, WISE Damper circular and WISE Damper

circular with spring return.

125

125

A

ø

C

Figure 1. Requires a straight section of 2 x Ø for sound attenua-

tors with baffle or centre body.

Installation – all designs

• WISE Dampers’ air flow measurement requires a straight

section before and after the product (in the air direction)

according to the installation figures.

• Instructions for Use are supplied with the product on

delivery, but can also be downloaded from www.

swegon.com.

Installation – circular version

• Installation is position dependent.

Figure 3. Straight section requirements, circular ducts.

1-5: Quantity Ø before the product: 0 x Ø.

6: Quantity Ø before the product: 2 x Ø.

*

Cleaning hatch

1.

2.

3

*

.

4.

5.

6.