POWER UNIT 6-33

Cylinder bore

Piston skirt diameter

74.000 – 74.020 mm

73.970 – 73.990 mm

(2.9134 – 2.9142 in)

(2.9122 – 2.9130 in)

Cylinder bore wear (difference)

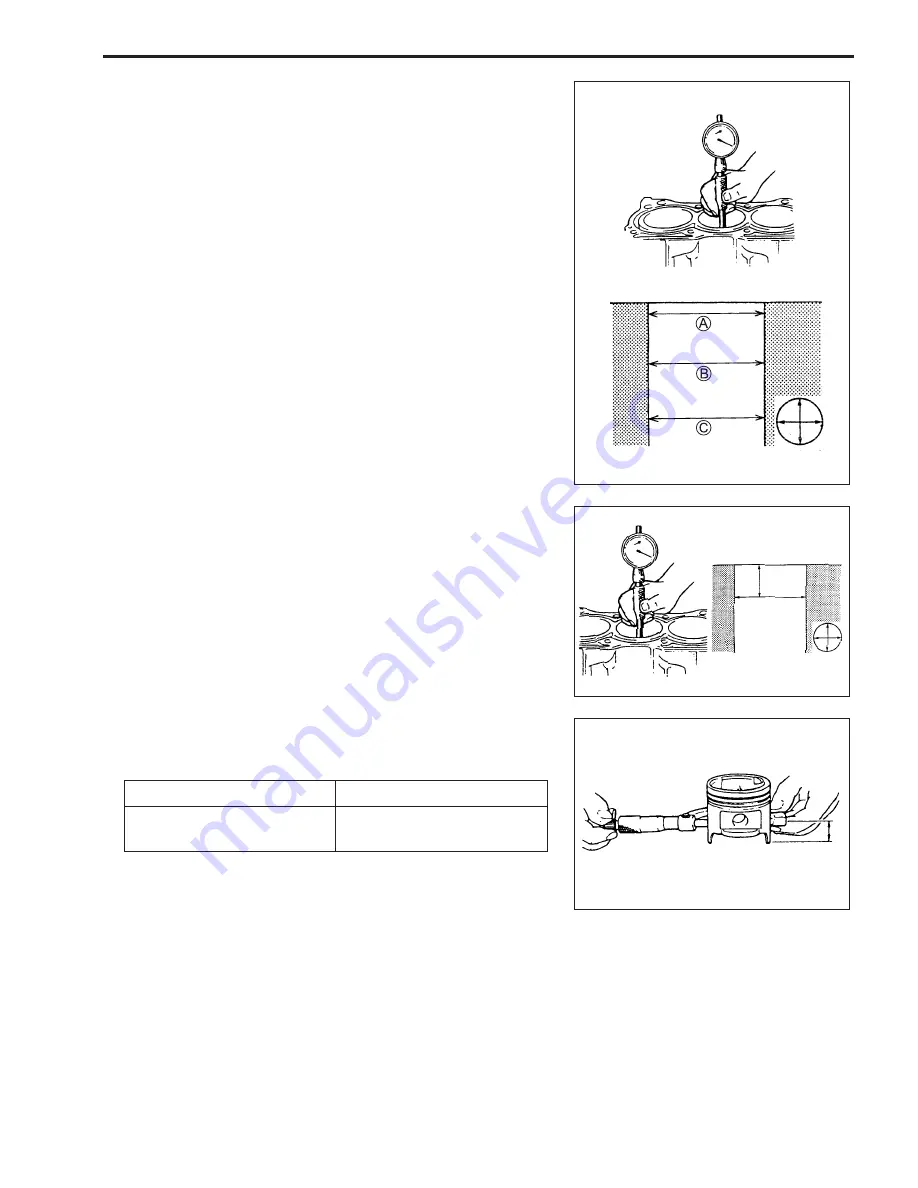

Measure the cylinder bore in the thrust and axial directions at

the three positions

A

,

B

and

C

as shown.

Check for the followings:

• Difference of the measurements at the two positions. (Taper)

• Difference between the thrust and axial measurement. (Out-

of-round)

$

09900-20508: Cylinder gauge set

Service limit: 0.100 mm (0.0039 in)

If the measurement exceeds the service limit, rebore or replace

the cylinder.

Piston to cylinder clearance

Standard

: 0.020 – 0.040 mm (0.0008 – 0.0016 in)

Service limit: 0.100 mm (0.0039 in)

If the measurement exceeds the service limit, replace the pis-

ton and/or the cylinder or rebore the cylinder.

To check the clearance, measure the following items:

• Cylinder bore at 50 mm elevation from the gasketed surface

• Piston skirt diameter at 15 mm elevation from the skirt end

$

09900-20508: Cylinder gauge set

09900-20203: Micrometer

Standard:

NOTE:

For this check, measure the cylinder bore and the piston skirt

diameter in the direction that makes a right angle with the crank-

shaft (piston pin).

50 mm

(2.0 in)

15 mm

(0.6 in)