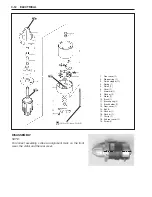

5-4 FUEL SYSTEM

Clamp (Clip)

Hose

Joint piep

3 – 7 mm

(0.1 – 0.3 in)

3 – 7 mm

(0.1 – 0.3 in)

20 – 30 mm

(0.8 – 1.2 in)

3 – 7 mm (0.1 – 0.3 in)

3 – 7 mm

(0.1 – 0.3 in)

20 – 30 mm

(0.8 – 1.2 in)

“A”

“B”

“C”

“D”

FUEL HOSE CONNECTION

Note that the fuel hose connection varies with each type of the

pipe. Be sure to connect and clamp each hose correctly by re-

ferring to the following figure.

• For the type “A” (short barbed end) pipe, hose should com-

pletely cover the pipe.

• For the type “B” (bent end) pipe, hose should cover straight

part of the pipe by 20 – 30mm (0.8 – 1.2 in).

• For the type “C” pipe, hose should fit up against flanged part

of the pipe.

• For the type “D” pipe, hose should cover the pipe by 20 –

30mm (0.8 – 1.2 in).

FUEL PRESSURE INSPECTION

1. Relieve the fuel pressure in line. (See the page 5-2.)

2. Remove the port side cover. (See the page 7-2.)

3. Remove the high pressure fuel filter from the intake mani-

fold.

4. Connect the special tools between the fuel feed hose and

the delivery pipe as shown in the figure.

5. Clamp the hoses securely to ensure no leaks occur during

checking.

$

09912-58442: Pressure gauge –

1

09912-58490: 3-way joint & hose –

2

09912-58432: Fuel pressure hose –

3

Delivery pipe

High pressure

fuel filter

1

3

2