6

4) Once the current has stabilized, a reading should be

taken and the anticipator adjusted to that value. If

longer heating cycles are desired, the anticipator can

be set to a higher value

2.5.2.

Ducts and filters

The ducts must be sized such a way as to accommodate the

specified airflow and the available static pressure. Refer to the

applicable local and/or national installation codes.

Insulate the ducts that lead through non-heated areas. Use

flexible supply and return air connectors to avoid the

transmission of vibration. To make the unit run even quieter,

the installer should:

1) Use two elbows between each outlet and the supply

and return air plenum;

2) Cover the vertical sections of the supply and return air

duct with soundproofing material;

3) Use baffles in short radius elbows;

4) Use flexible hangers to suspend the ducts.

The

SUPREME

furnace is equipped with a filter frame for the

blower compartment. It must be installed on the outside of one

of the three sides or the bottom of the furnace. Once the

location of the installation has been determined, use the four

square knockouts for ease of cutting the opening.

A heat pump or an air conditioner can be added to this furnace,

in either the supply or return air duct. Carefully follow the

instructions provided with these appliances to ensure proper

installation and hook-up to the electric furnace. Refrigerant and

drainage pipes must in no way hinder access to the furnace

panels.

2.6 SUPPLY AIR ADJUSTMENTS AND

OTHER BLOWER SETTINGS

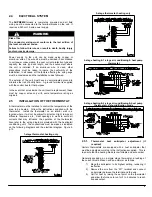

Fan Control Board taps are used by the installer to configure a

system. The ECM motor uses the selected taps to modify its

operation to a pre-programmed table of airflows (Refer to Table

3 and Table 4). Airflows are based on system size or mode of

operation and those airflows are modified in response to

thermostat inputs.

FEM electric furnace must be configured to operate properly

with system components with which it is installed. To

successfully configure a basic system (see information printed

on circuit board label located next to select pins), move the 6

select wires to the pins which match the components used.

(Refer to Figure 4 below)

Figure 4

Fan Control Board

2.6.1.

HEAT KW/CFM adjustment

Installer must verify (factory set) the electric heat airflow

adjustment required for kW size heater installed.

The select pins are marked 23, 20, 18, 15 (for ½ HP ECM motor

unit) and 27, 23, 20, 18 (for 1.0 HP ECM motor unit). Refer to

the unit wiring diagram and select the pin for the heater size

being used (Refer to Figures 4 and 9).

The airflow must be large enough for safe and continuous

operation. (Refer to Table 3 and 4 for airflow delivery CFM).

2.6.2.

AC/HP size

Select System Size Installed

The factory setting for air conditioner or heat pump size is the

largest outdoor unit that can be used with the furnace. Installer

needs to select air conditioner or heat pump size to ensure that

airflow delivered falls within proper range for the size unit

installed.

The select pins are marked 036, 030, 024, 018 for furnace

equipped with ½ HP ECM motor and 060, 048, 042, 036 for

furnace equipped with 1.0 HP ECM motor. Refer to the unit

wiring diagram and select the pin for the outdoor unit size being

used (Refer to Figures 4 and 9).

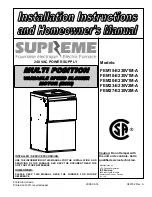

Summary of Contents for FEM15-E230V1M-A

Page 12: ...12 FIGURE 9 Diagramme électrique ...

Page 17: ...17 COMPOSANTES ET PIÈCES DE REMPLACEMENT ...

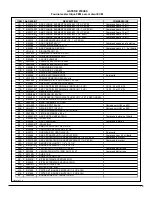

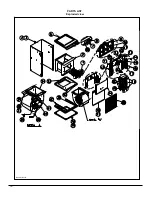

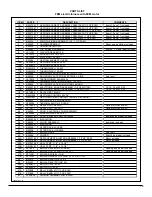

Page 18: ...18 LISTE DE PIÈCES Vue explosée B50081 Rev B ...

Page 31: ...12 FIGURE 9 Electrical Diagram ...

Page 36: ...17 COMPONENTS AND REPLACEMENT PARTS ...