5-9

Chapter 5: Chassis Setup and Maintenance

Permanent and Optional Standoffs

Standoffs prevent short circuits by securing space between the motherboard and

the chassis surface. The SC823M chassis includes permanent standoffs in locations

used by most motherboards.

Some motherboards require additional screws for certain CPUs, heatsinks, and

other components. Optional standoffs are included for these motherboards. To use

an optional standoff, screw the standoff into the chassis and use it in the same

manner as the permanent standoffs.

Installing the Motherboard

1. Review the documentation that came with your motherboard. Become familiar

with component placement, requirements, precautions, and cable connec-

tions.

2. Power down the system and remove the power cords from the rear of the

power supplies as described in Section 5-2. Remove the chassis cover as

described in Section 5-3.

3. As required by your motherboard, install standoffs in any areas that do not

have a permanent standoff. All motherboard mounting holes should have

matching chassis standoffs. If there are additional standoffs in the chassis that

are not used by the motherboard, remove them. Do not allow extra standoffs

to remain in the chassis if they are not being used by the motherboard.

4. Lay the motherboard on the chassis aligning the permanent and optional

standoffs. In addition, make sure the motherboard aligns with the I/O shield.

5. Secure the motherboard to the chassis using the rounded, Phillips head

screws.

6. Secure the CPU(s), heatsinks, and other components to the motherboard as

described in the motherboard documentation.

Figure 5-10. Motherboard Standoffs and Motherboard Pan Head Screw

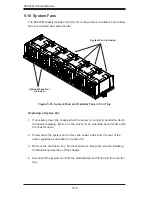

Flat head

M4 x 4 mm

[0.157]

RAIL

Round head

M4 x 4 mm

[0.157]

Flat head

M5 x 12 mm[0.472]

Washer for M5

DVD-ROM CD-ROM FLOPPY DRIVE

Flat head

6-32 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

Round head

3 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

M/B

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Thumb screw

6-32 x 5 mm [0.197]

M/B standoff

6-32 to 6-32

M/B STANDOFFS

M/B (CPU) standoff

M5 to 6-32

Round head

2.6 x 5 mm

[0.197]

Flat head

M4 x 4 mm

[0.157]

RAIL

Round head

M4 x 4 mm

[0.157]

Flat head

M5 x 12 mm[0.472]

Washer for M5

DVD-ROM CD-ROM FLOPPY DRIVE

Flat head

6-32 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

Round head

3 x 5 mm

[0.197]

Pan head

6-32 x 5 mm

[0.197]

M/B

Flat head

6-32 x 5 mm

[0.197]

HARD DRIVE

Thumb screw

6-32 x 5 mm [0.197]

M/B standoff

6-32 to 6-32

M/B STANDOFFS

M/B (CPU) standoff

M5 to 6-32

Round head

2.6 x 5 mm

[0.197]

Summary of Contents for SC823MTQ-R700LPB

Page 5: ...v Preface Notes ...

Page 12: ...SC823M Chassis Manual 1 4 Notes ...

Page 32: ...2 20 SC823M Chassis Manual Notes ...

Page 60: ...SC823M Chassis Manual 5 22 Notes ...

Page 70: ...SC823M Chassis Manual 6 10 Notes ...

Page 72: ...SC823M Chassis Manual A 2 Notes ...