Superabrasive

User

Manual

Original

Language

Lavina®

25G

‐

X

2/2015

24

8.11 TENSIONING AND REPLACING THE BELTS

The

transmission

of

the

machine

has

two

timing

belts

(main

belt

and

planetary

belt)

of

maintenance

free

type.

To

change

the

main

belt

you

have

to

remove

all

holders

and

dismount

their

adaptors.

Dismount

the

sealing.

Carefully

check

the

friction

surface

(flanges

of

the

lower

cover

and

the

outside

diameter

of

the

adaptors).

Decide

if

they

are

in

good

condition

(wear

out,

smoothness

of

surface)

and

whether

they

can

work

until

next

inspection.

Remove

the

bottom

cover,

unscrew

the

bolts

on

the

outskirt

and

the

three

bolts

of

the

spacers

(

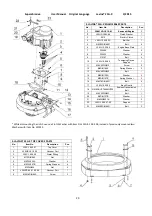

Fig.

8.11.1).

Under

the

cover

on

the

outskirt

there

is

a

sealer,

and

the

spacers

have

O

‐

Rings.

The

change

of

all

seals

together

with

the

belts

is

recommended.

Fig.8.11.5

shows

the

scheme

of

belts

location.

To

dismount

the

old

belts

first

dismount

the

planetary

belt

pos.1

and

after

that

the

main

belt

pos.6.

To

dismount

the

main

belt

pos.6

unscrew

nuts

on

pos.4

and

pos.5

enough

to

be

able

to

turn

the

tensioners

pos.3

around

the

central

axle.

Clean

the

washers

and

space

around,

and

check

if

all

bearings

of

pulley

units

or

tensioners

are

in

good

condition

(check

for

too

much

clearance

or

rolling

noise).

Rotating

the

tensioner

will

allow

the

centre

distance

to

be

reduced

in

such

a

way

that

the

timing

belt

may

be

fitted

without

force.

Installation

with

the

use

of

force

is

NOT

permissible

at

any

time

as

this

can

damage

the

high

quality,

low

stretch

tension

cord

and

other

components.

This

damage

is

often

not

visible.

Put

the

belts

in

pos.6

as

per

the

scheme,

and

pay

attention

for

their

correct

position

in

every

pulley.

Screw

up

until

it

stops

and

loosen

on

the

half

moons

the

nuts

on

pos.4,

allowing

the

rotation

of

the

tensioners

at

minimum

inclination.

Using

nuts

on

pos.5

tighten

the

belt,

verifying

again

the

correct

position

of

the

belt,

and

the

correct

gearing

in

every

pulley.

Rotate

the

gear

while

tensioning

to

allow

regular

tension

distribution

on

the

belt.

Control

the

tension

using

Frequency

tension

Tester

(Optibelt

3

TT)

(Fig.

8.7.3).

Tension

in

span

“

А

”

of

the

belt

should

be

120

‐

130Hz.

It

is

possible

for

tensioning

while

changing

the

belt

to

use

pre

‐

installed

support

(Fig.8.11.5

‐

2)

(Fig.8.11.6)

(only

when

its

factory

position

is

not

changed),

to

limit

the

turn

of

the

tensioner

when

the

required

belt

tension

is

done.

ATTENTION:NEVER

“OVER”

TENSION

THE

BELT,

THE

BELT

WILL

BE

DESTROYED

AND

IT

WILL

NEVER

RECOVER

ITS

ORIGINAL

TENSION

To

dismount

the

planetary

belt

(Fig.8.11.5

‐

1)

unscrew

the

screw

of

the

front

washer

(Fig.8.11.7)

and

the

two

screws

of

the

conical

sleeve

(Fig.8.11.8).

Screw

one

screw

in

the

free

thread(Fig.8.11.9),

to

push

the

washer

down

(Fig.8.11.10);

take

the

conical

sleeve

and

the

belt

(Fig.8.11.11).

You

can

help

with

a

flat

screw

driver

if

the

sleeve

is

not

going

out

easy.

(Fig.8.11.12).

Figure 8.11.3

Figure 8.11.1

Figure 8.11.2

Figure 9.7.4

Figure 8.11.5

Figure 8.11.6