Superabrasive

User

Manual

Original

Language

Lavina®

25G

‐

X

2/2015

17

CHECK

AND

REPLACE

EVERY

200

WORKING

HOURS

Every

200

working

hours

the

operator

should

inspect

all

parts

of

the

machine

carefully.

Most

importantly,

inspect

and

clean

the

tool

plate

connections,

vacuum

hoses

and

water

tank.

Also,

check

the

water

flow.

Check

the

guard

assembly.

Make

certain

the

wheels

are

clean

and

rotate

properly.

Inspect

the

control

buttons.

If

there

are

defective

control

parts,

they

should

be

replaced

immediately.

Replace

worn

vacuum

‐

and

water

hoses.

Carefully

inspect

the

seal

rings

and

bearings

of

the

grinding

units,

and

replace

any

showing

signs

of

excessive

wear.

For

more

information,

refer

to

chapter

troubleshooting

below.

Open

the

service

cover

on

the

motor

base

(Fig

7.2)

(Fig

7.3)

to

check

of

the

planetary

chain.

Lubricate

the

chain

with

special

lubricant

for

chains

and

correct

the

sag

if

needed

.

For

sagging

correction

(See

TROUBLESHOOTING

)

.

Dismount

the

tool

holders

(See

Troubleshooting)

replace

all

parts

(elastic

element,

buffers,

sealers)

with

the

slightest

damage

or

consume.

Return

machine

to

authorized

service

center

for

overall

checkup

of

the

Engine.

For

Propane

safety,

have

the

machine

serviced

by

a

Certified

Technician

,

including

emission

check.

CHECK

AND

REPLACE

EVERY

400

WORKING

HOURS

Besides

the

checks

of

200

working

hours,

replace

sealer

and

V

‐

rings

like

described

in

chapter

“TROUBLESHOOTING

REPLACING

BELT

AND

PULLEY

UNITS.

Check

if

belts

and

bearings

are

in

good

condition,

change

if

needed.

Return

machine

to

authorized

service

center

for

overall

checkup

of

the

Engine.

For

Propane

safety,

have

the

machine

serviced

by

a

Certified

Technician,

including

emission

check.

VACUUM

As

stated

previously,

frequently

check

hoses

and

othe

r

parts

for

clogging.

WATER

LEAKS

Replace

any

leaking

parts

immediately

as

the

water

could

damage

your

machine

MECHANICAL

PARTS

Parts

such

as

the

belts,

seal

rings,

cap

rings,

spiders

and

buffers

and

guard

assembly

are

subject

to

wear

and

should

be

replaced

as

needed.

ELECTRICAL

SYSTEM

Dust

should

not

enter

the

control

box,

as

it

will

destroy

the

contacts.

Remove

(blow

out)

any

dust

present.

Electrical

schemes

with

Kawasaki

Engine

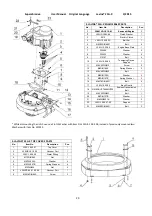

Figure 7.2

Figure 7.3