Questions? Call or Text +1-801-658-0015 •

15

The Micro Welder Experts

settings and connections. Verify that the Weld On/Off

button is in the on state. If you need assistance, call the

Sunstone Customer Service team at +1 801-658-0015

or send a message to [email protected].

Weld Head Control Screen

Operation

The Weld Head Control Screen is used to set all param

-

eters required for controlling a connected weld head

during the weld process.

Note: The Weld Head Control Screen icon only appears

when a weld head is connected and powered on.

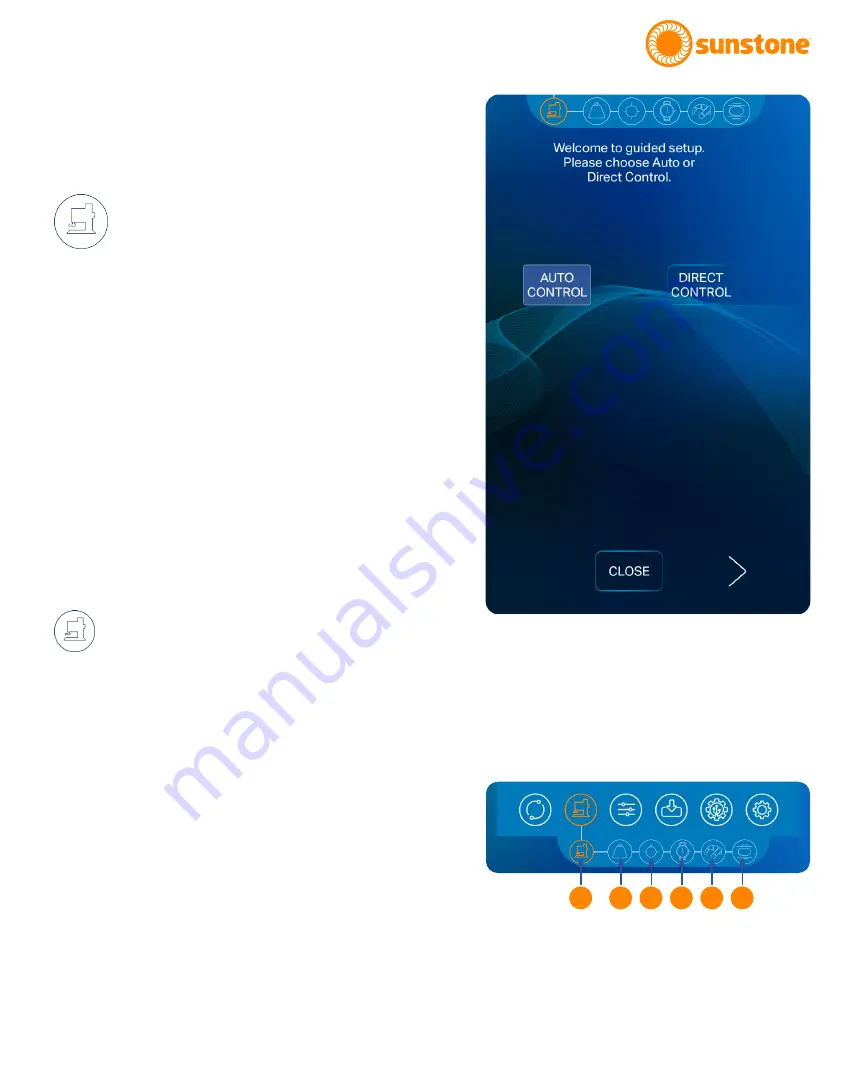

When you press the Weld Head Control Screen Icon

in the Navigation Bar, the Pico will begin a sequence

of step-by-step, pop-up windows to guide you

through the setup process.

You can choose to follow the step-by-step setup

process or jump to any portion of the setup process

by pressing any of the icons in the Weld Head Control

sub-navigation bar (found under the Navigation Bar

when the Weld Head Control icon is pressed). See Fig

-

ure 15.2.

MODE SELECT

The first step of the set up process is choosing

how you wish to control the weld head. The Mode Se

-

lect icon (A) in Figure. 15.2, is identical to the Weld Head

Control Screen icon due to it being an extension of

the weld head controls. The weld head has two modes

available: Direct Control and Automatic Control.

Direct Control

Direct Control allows operators to control the position

of the weld head directly by using an analog foot pedal.

The position of the weld head corresponds to the posi-

tion of the foot pedal. Pressing down on the foot pedal

lowers the weld head; letting up on the pedal raises the

weld head.

In this mode, the operator presses the analog foot

pedal to lower the weld head until contact is made with

Figure 15.1. The Weld Head Control Screen in the Mode

Select step. When you touch the Weld Head Control Screen

icon, the Pico will want to walk you through a step-by-step

process to complete the weld head setup process. When

you’ve selected the desired settings for each step, press the

right arrow button at the bottom of the screen to advance to

the next step. You can press the left arrow button to go back.

Press the Close button to save and end the setup process.

A

B C D E F

Figure 15.2. The Weld Head Control Screen sub-navigation

bar contains six areas of weld head control: Mode Select

(A), Force (B), Position (C), Timing (D), Speed (E), and

Displacement (F).

Summary of Contents for PicoDC

Page 1: ...Direct Current Resistance Welder Users Guide 20210615 PART 1230 Pic...

Page 4: ...Users Guide Pic...

Page 41: ...Questions Call or Text 1 801 658 0015 37 The Micro Welder Experts...

Page 42: ...38 Questions Call or Text 1 801 658 0015 Users Guide Pic...

Page 43: ...Questions Call or Text 1 801 658 0015 39 The Micro Welder Experts...