34

88

Maintenance and repair

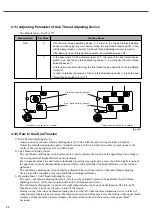

8.1) Adjustment of Thread Take-up Lever

Spring

1) Loosen the stopper tightening screw

①

as in the

figure and turn the thread take-up spring stopper

②

counterclockwise. Then the operating scope of the

thread take-up lever spring becomes narrower.

Otherwise, the operating scope becomes wider.

※

The standard operating scope of the thread take-

up lever is 5~10mm.

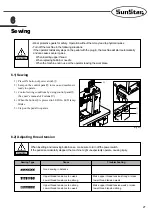

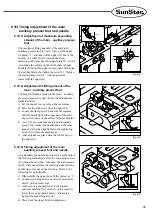

2) Adjustment of Thread Take-up Lever Spring Tension

Loosen the thread adjusting device shaft nut

①

and turn the groove of the thread adjusting device shaft

②

clockwise using a

screwdriver. Then the tension of the thread take-up spring

③

becomes stronger. Otherwise, it gets weaker. [Fig. 8-2]

3) Adjustment of Thread Take-up Lever Spring Operation Timing

Loosen the stopper screw

④

and turn the thread take-up spring guide

⑤

clockwise. Then the thread take-up

spring

③

’s operation timing gets faster. Otherwise, the operation timing gets slower. [Fig. 8-3]

※

The operation timing of the thread take-up lever spring is standard when the stopper screw

④

is at the center

of the guide plate

⑤

.

[Fig. 8-1]

[Fig. 8-2]

[Fig. 8-3]

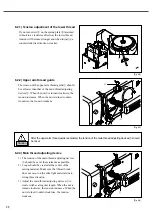

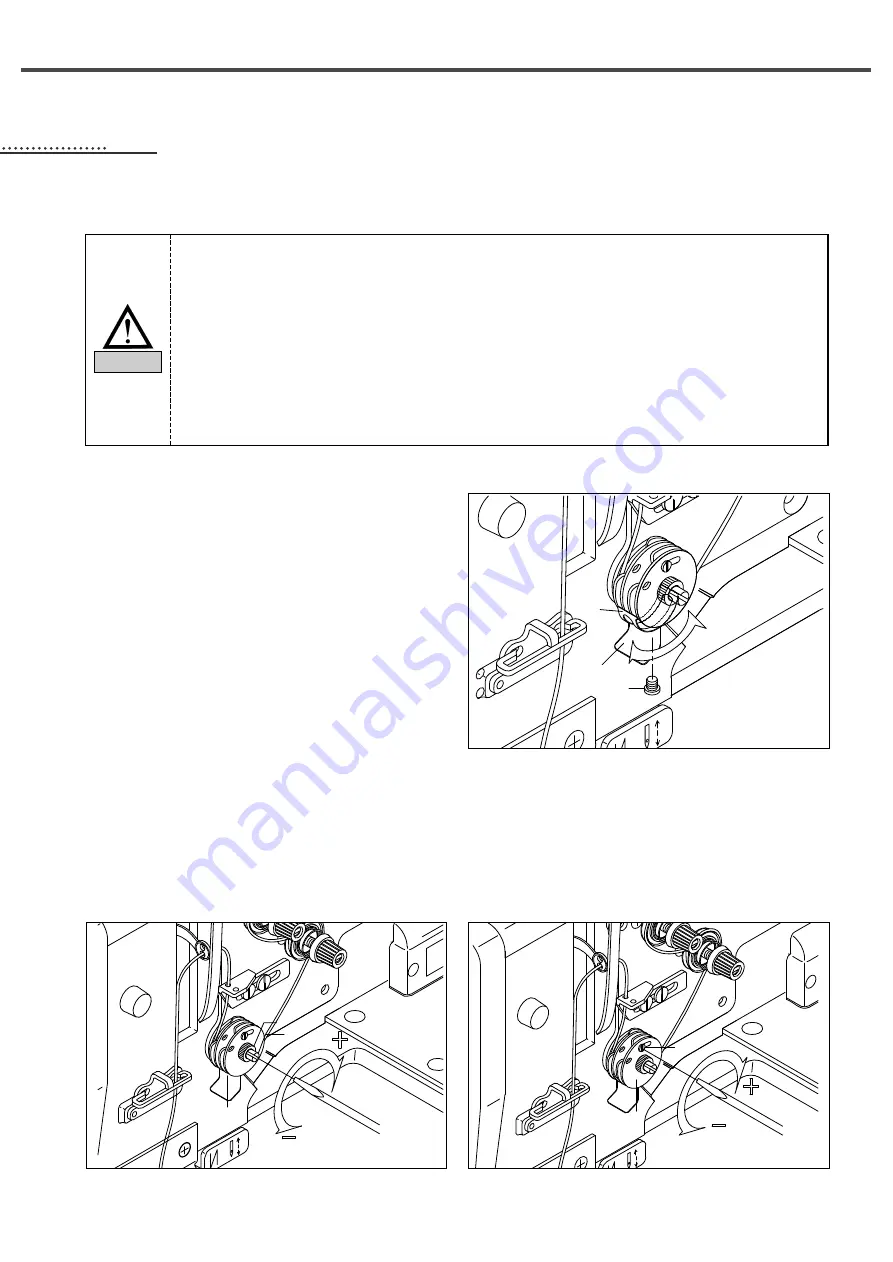

•

For machine maintenance and repair, consult with qualified technicians.

•

For electrical maintenance and repair, consult with qualified technicians or agencies.

•

When safety devices are disassembled, make sure to return them to original positions.

•

Use both hands when bending the machine backwards or returning it to the original position. Using

only one hand can lead to severe hand injuries due to the weight of the machine.

•

Turn off the switch and pull the plug. Pressing pedal by mistake may result in physical injuries.

-

Inspection, maintenance, repair

-

Exchanging expendable parts such as needle, hook, knife.

-

Adjusting hook oil flow

•

In case you operate the machine when the power is on, please take special precaution.

Caution

①

②

③

①

③

④

⑤

②

Summary of Contents for KM-1080 Series

Page 2: ......

Page 13: ...13 4 4 2 Flat table Fig 4 4 ...