7-47

Place the cursor at

“

2.DESIGN

DIVIDE

”

and press

�

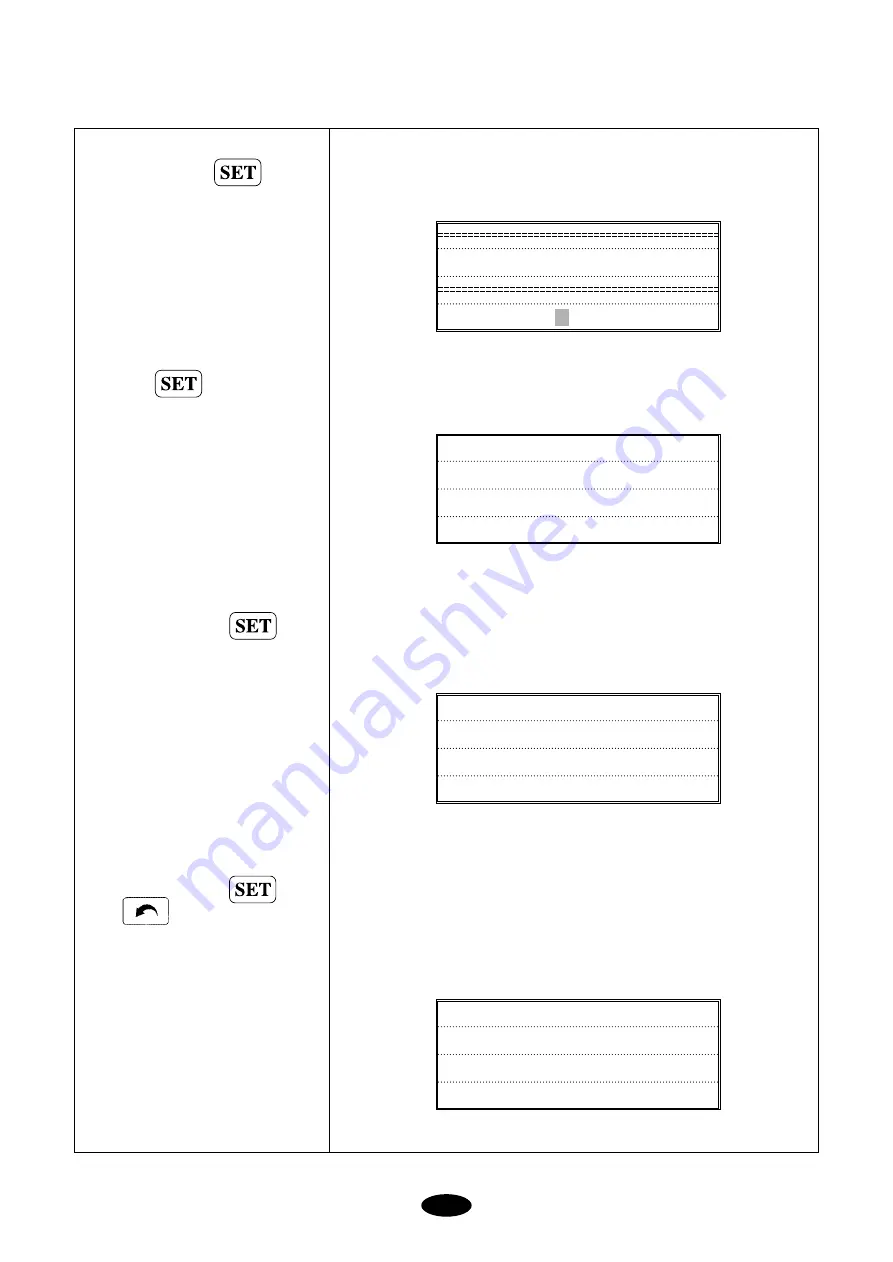

DESIGN DIVIDE

STITCH= [ST]

Input 1000 using the numerical keys

and press

�

SELECT EMPTY ROOM

===> # 18

To store sub-design 1, select #35

using the cursor. Press

�

SELECT EMPTY ROOM

===> # 35

To store sub-design 2, select #36

using the cursor. Press

Press if you do not want to

store the sub designs

�

No.

:

5

NAME

:

SWF002

STITCH

:

18294

COLOR

:

7